augiedoggy

Well-Known Member

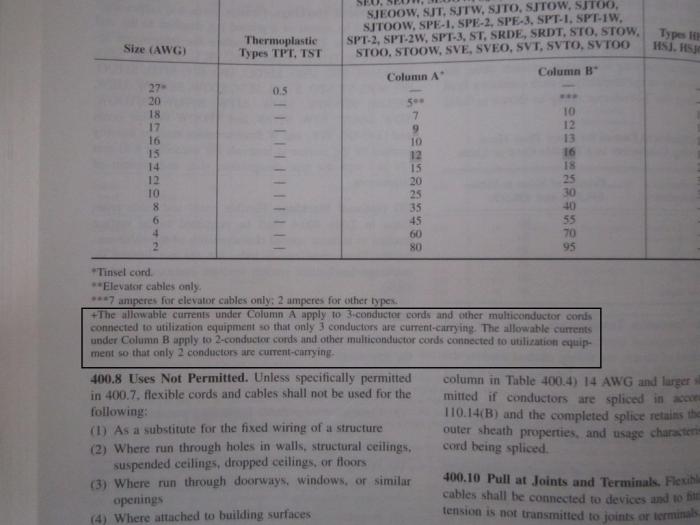

Yep! This is just a friendly conversation about wire types and some sharing and learning of the NEC. I did look at NFPA 79 last night and it agreed with Jerz - 14awg = 15a, 12awg = 20a, 10awg = 30a, etc, without specifying any difference between THHN, MTW, or others that I dont recall off hand.

But - NFPA 79 is more about wiring practices within machine tool electrical panels. It assumes initial ampacities from NFPA 70 - NEC.

And I was just offering my experiences with machinery I service and the long term effects of the current on the wiring in some cases...

BTW I took a look at some of the wiring harnesses in my garage and most of the wiring for the heating elements is 12 gauge not 10 as I originally thought (which makes more sense). and the heat damage on those was mainly at the spade connectors so I believe poor connections cause things to heat up and it had nothing to do with the choice of wiring as I originally thought it could have.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)