Heitdj22

Active Member

- Joined

- Nov 11, 2020

- Messages

- 35

- Reaction score

- 6

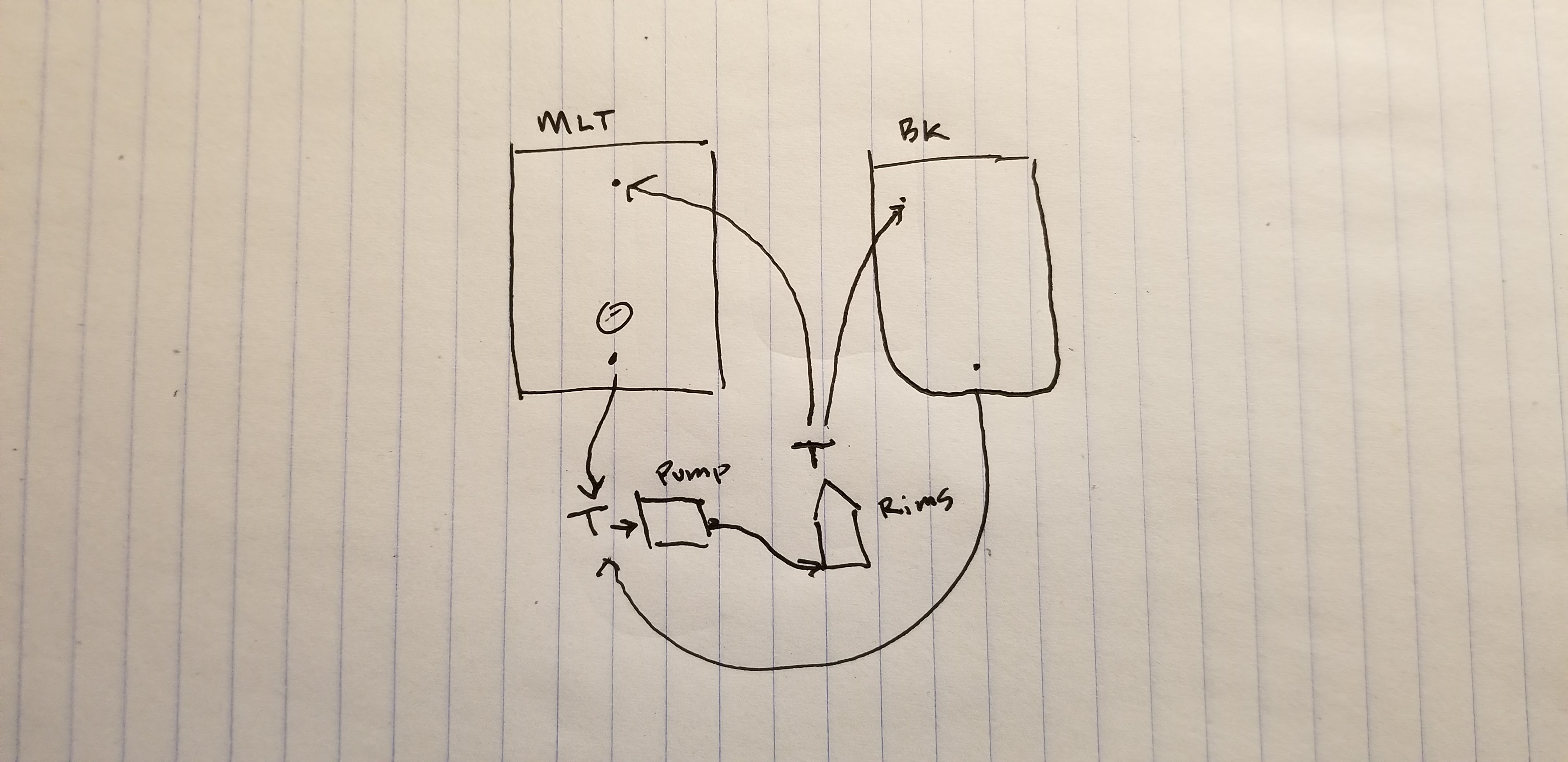

Hi all, I am currently in the market to upgrade my brewing to a 2V all grain setup. I am having trouble deciding port locations on spike kettles. I made a diagram on my phone and wondering what I am missing or need to implement into my brew system. This is the setup I was thinking.

MT

Bottom drain port

Temp/ possible whirlpool port

Sparge port

BK

Bottom drain port

Whirlpool port

Top recirculation port

2 pumps

1 rims tube

2 thermowells (1 at the rims tube, and 1 at the pump nearest the BK).

The red t is possibly thinking a 4 way valve.

Is this seeming logical for 3 ports on each kettle?

any advice is appreciated.

Thanks!

MT

Bottom drain port

Temp/ possible whirlpool port

Sparge port

BK

Bottom drain port

Whirlpool port

Top recirculation port

2 pumps

1 rims tube

2 thermowells (1 at the rims tube, and 1 at the pump nearest the BK).

The red t is possibly thinking a 4 way valve.

Is this seeming logical for 3 ports on each kettle?

any advice is appreciated.

Thanks!