user 263363

Well-Known Member

- Joined

- Feb 18, 2019

- Messages

- 1,199

- Reaction score

- 7,058

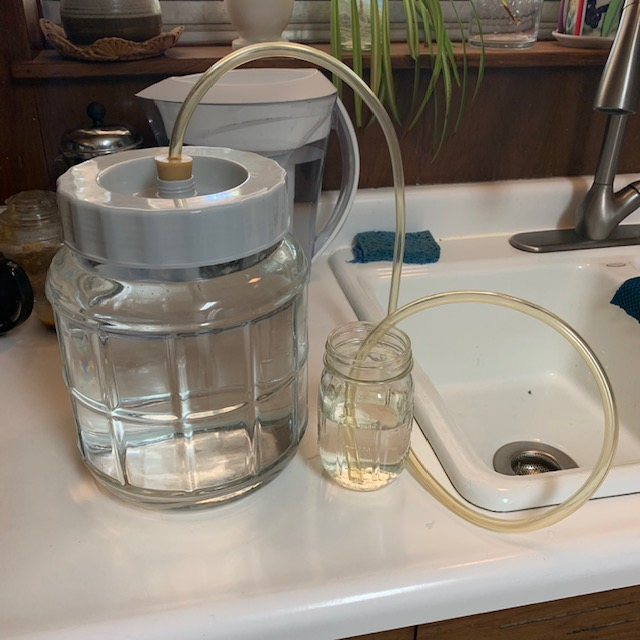

I use the Little Big Mouth Bubblers for my one gallon test batches. No spigot so I have to siphon. Very easy to clean, as you point out. I don't care for the lid gaskets so I bought a thin sheet of silicone and had the local HS Technology teacher cut out some gaskets on his laser trimmer for me. And finally, yes, I also have trouble removing the lids after fermentation is complete. I use something similar to these which makes it a bit easier.

That seems like a simple solution for the troublesome lid. I also like the idea of the silicone gaskets. I’ll see if the mechanics at work can hook me up. Thanks!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)