Brew-ta-sauraus

Well-Known Member

subscribed

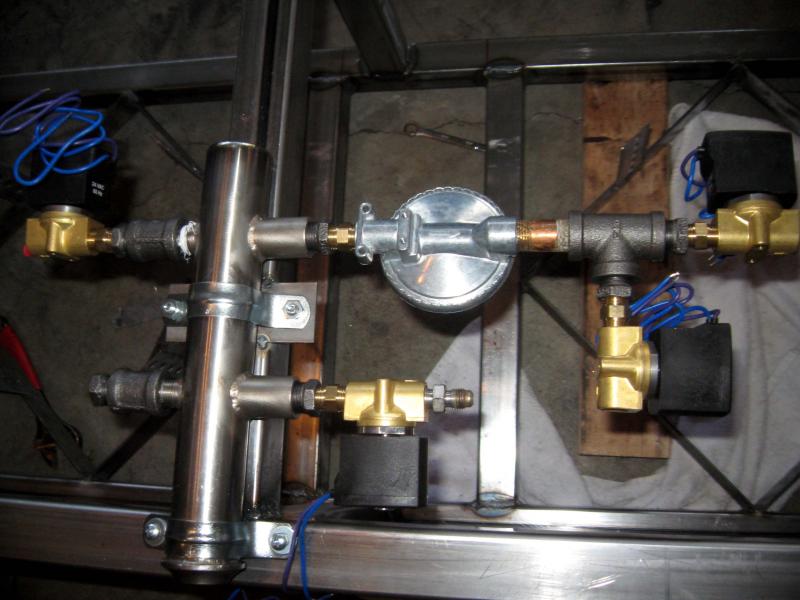

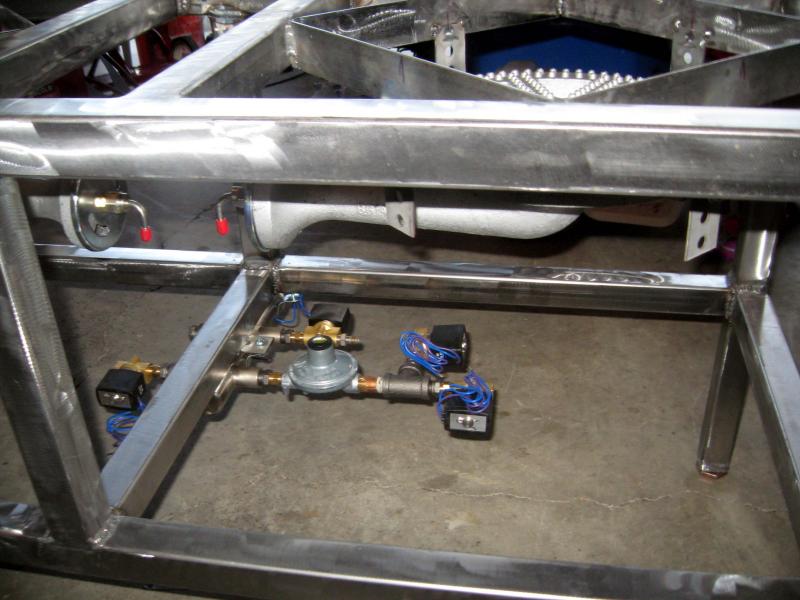

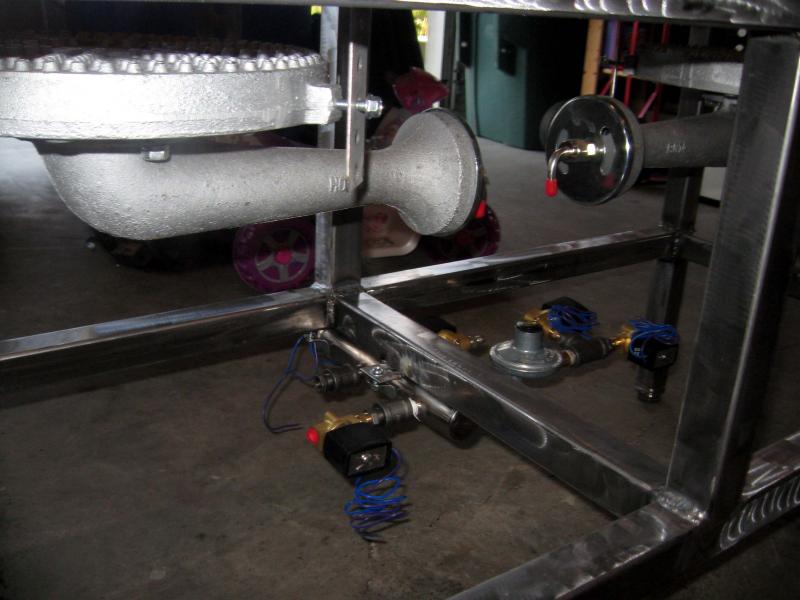

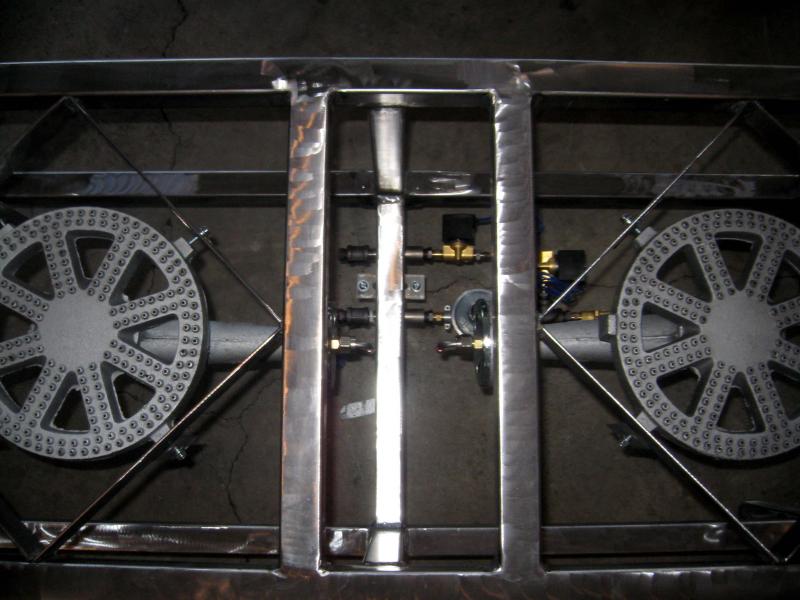

Jaybrinks said:I could not find a jet burner that could boast 210,000 btu's like the Hurricanes do. They may be out there, but I did not find one. We also like the flexibility that the hurricanes offer. I can crank up the pressure to full blast....or back it way down for a tiny gentle flame....and they are nice and quiet.... there are fewer leak points to worry about as well....I'm sure we could have made the Jet Burner's work..but after a lot of research, these seemed like a good fit for us......I guess we will really find out once we do our first test run..

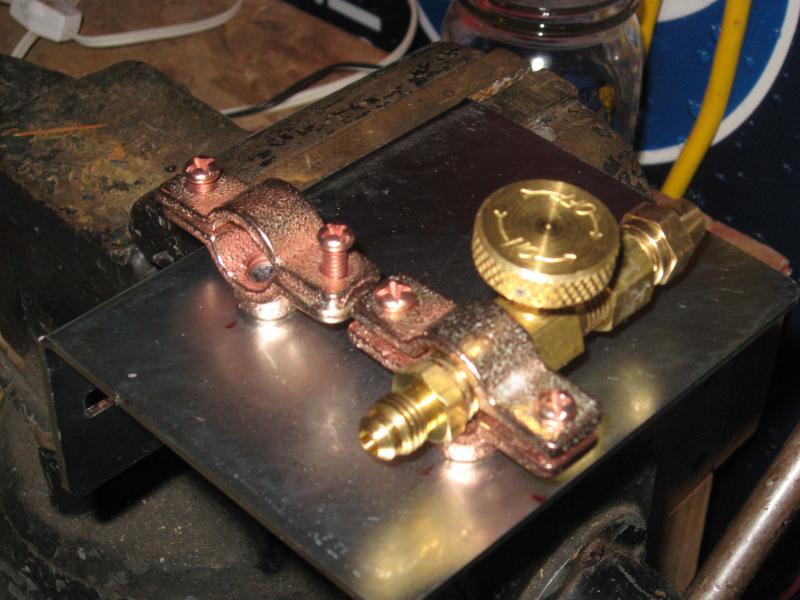

The High/Low pressure piping was only complicated at first...it is actually pretty simple to do...which allows us the full flexibility of using the Hurricanes on high pressure safely, getting the higher btu's.....and having adjustability.

So are you guys bottling or is your beer only available at a pub? I'd sure like to sample what you're brewing.

cheers