You have chick hands or was that your wife's hands?

These are the hands of creation!!! Don't you have some kegs to clean?

You have chick hands or was that your wife's hands?

All for the love of beer! Well done man! Well done!

Cheers

Jay

Looking good, I am working towards a similar sized system, but probably using a hybrid gas/electric setup for the hlt at least (propane costs add up quickly for me). How well does your stand design support the weight of the kettles? Have you filled them up to test yet? Any bowing in middle? Thanks for the help and documentation!

This build is very interesting and I am loving the progress. I was thinking about picking up the 210,000 btu hurricane for a 55 gal boilermaker. I would love to hear how it works on your system.

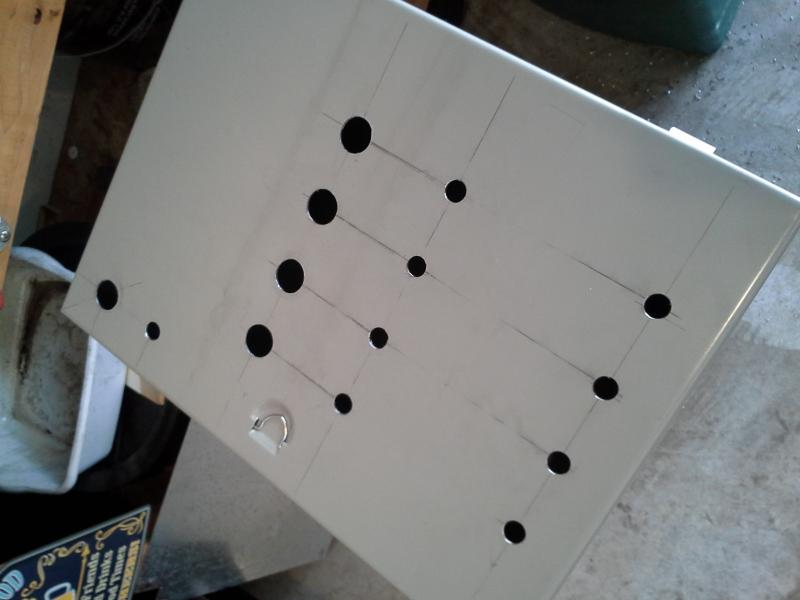

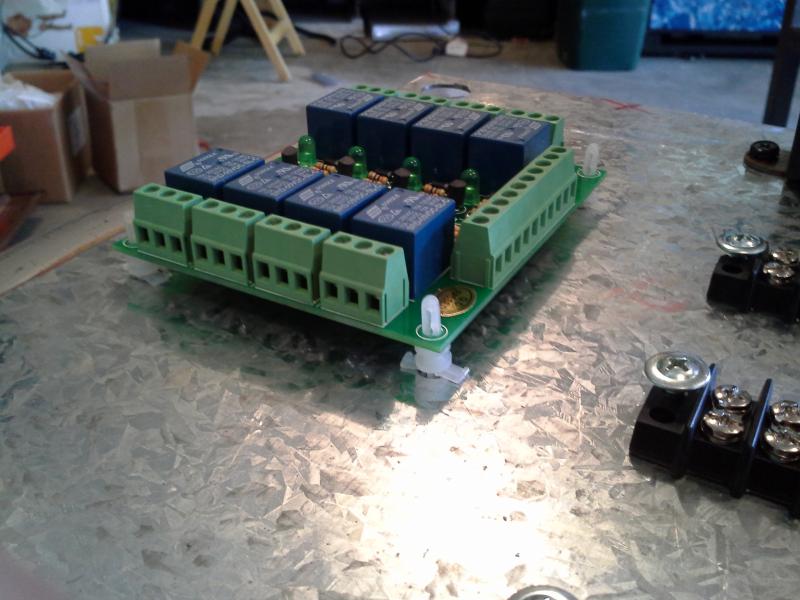

Got most of the wiring done in the control panel....still have to wire up the temp sensors, fuses, etc......clean some things up and make the end connector for the wiring harness that will connect to the stand.

I broke an LED so am waiting for the replacement to show up as well...arrgh.

We are close to firing this thing up!!