Weezy

Well-Known Member

At long last, my brew room is complete! I have a 7'x12' room in the basement now insulated, plumbed, and wired for brewing. There's an all-in-one ss sink & counter at one end, salvaged from a 60s kitchen. The other end is the 4-tap Keezer. The brew table is on the long wall in between. The SS counter was donated by a friend. I just had to build legs for it (the sink too). There's a SS 36" stove hood over the table that vents out of a small, louvered vent window.

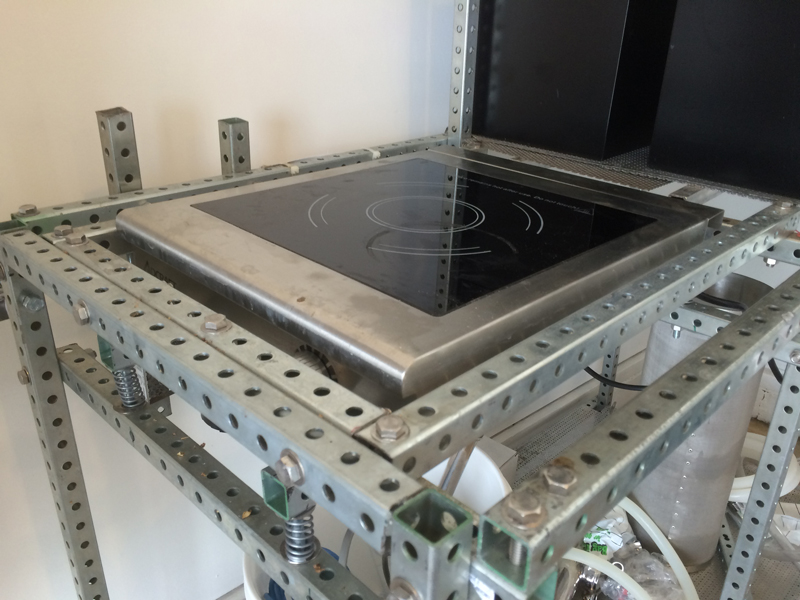

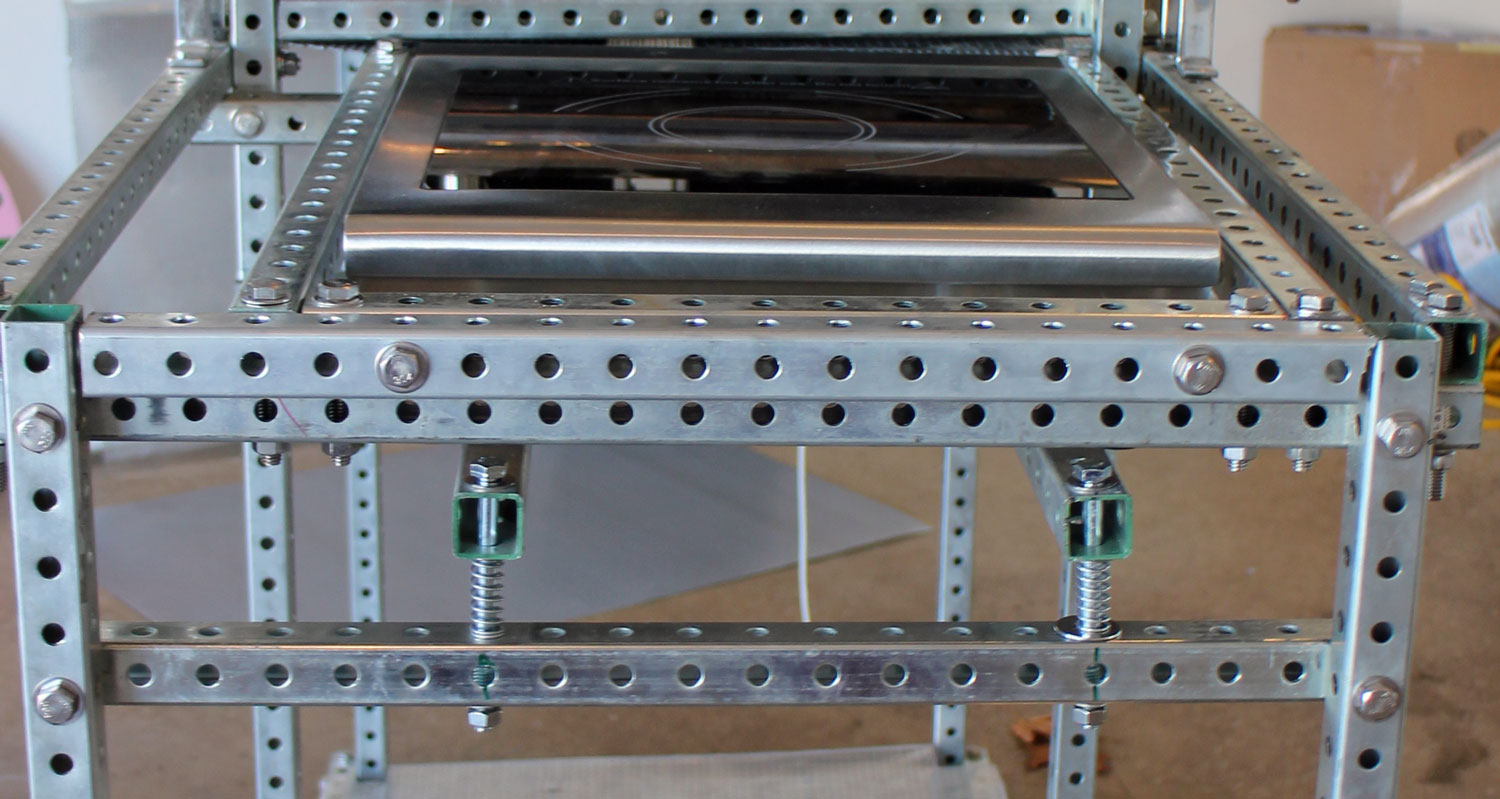

I was so glad to get everything buttoned up over the holiday vacation. Got the rig built. The pic is of a cross circulation running warm pbw through everything. Then got ready to brew...AND I BROKE MY GRAIN MILL!!!! So I haven't brewed in the new room yet. Tonight I plan a nice simple smash brew to try it all out.

The BK is on left on an Avantco 3500W. The MLT is on the right on an Avantco 1800W, that has been modified to use an external temp probe, so that the onboard temp controls work very precisely. I haven't decided if I'll mod the 3500 yet. We'll see how it goes. In the middle is my dual 12V pump box. I have posts here on the pump box and the induction mod. Tubing is 3/8" thick walled silicone connected to 1/2" PEX nipples. It fits so snug I don't need any tube clamps, even under max pump pressure. It works out great.

Basic brewing process is...

- Fill MLT with strike water and BK with sparge water.

- Heat strike water in MLT

- Go crush grain while strike water heats up

- Dough in using paint strainer bag in MLT, stir, set pump to recirculate

- Set BK to heat sparge water, recirculate

- Once sparge water is at temp (shooting for ~20 min), set pumps to cross recirculate very slowly for 30-45 minutes. Let the SG normalize and grain bed settle and filter the fines.

- Move all wort to BK and boil.

Wish me luck and thanks to all the good folks at HBT for all the great input over the years!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)