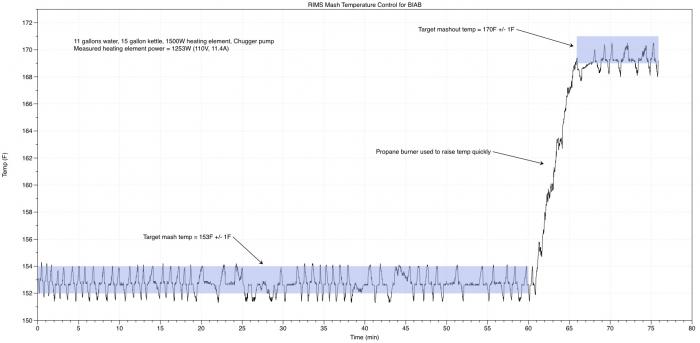

I've been brewing BIAB on a propane-fired system for about a year and have just completed a build of a RIMS system to help control mash temperature and free up some brewday time by avoiding kettle babysitting duty during mash/mash-out. Propane would still be used for initial heating and for the boil.

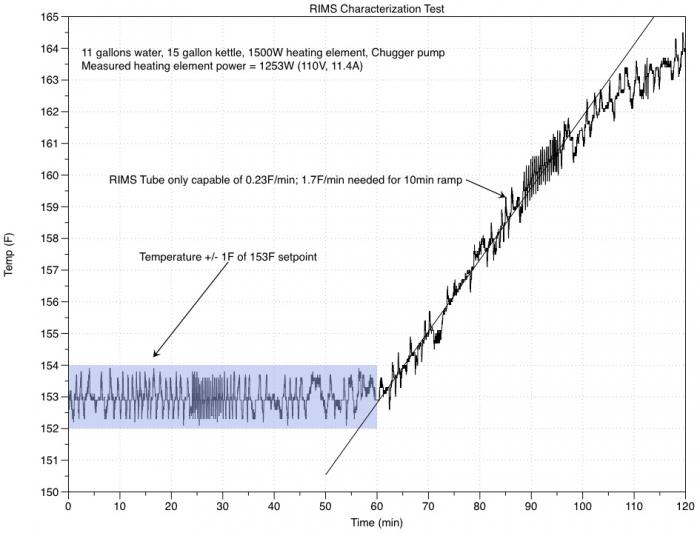

My original goal was to build a programmable PID-controlled, 120V/15A system that could handle both single and multi-step mash profiles. Unattended multi-step profiles ended up not being possible due to capacity of the heating element (more in a later post), but in the end the system does a great job of tightly controlling mash temp at a programmed set point with no active monitoring needed.

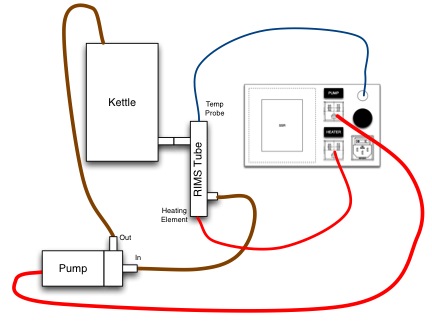

One concern was whether or not a 1500W (about the max usable on a 120V/15A circuit) heating element could even maintain temp. I have a 15G brew kettle and want to be able to do 10G batches. I set up an experiment to see how much heat was lost from the kettle when filled with 10G of mash-temperature water -- see diagram below. The kettle/water lost about 0.22C per minute which, if my thermodynamic calculations are correct, corresponds to about 550W. Making up for the kettle's heat loss seemed well-within the capabilities of a 1500W element.

My original goal was to build a programmable PID-controlled, 120V/15A system that could handle both single and multi-step mash profiles. Unattended multi-step profiles ended up not being possible due to capacity of the heating element (more in a later post), but in the end the system does a great job of tightly controlling mash temp at a programmed set point with no active monitoring needed.

One concern was whether or not a 1500W (about the max usable on a 120V/15A circuit) heating element could even maintain temp. I have a 15G brew kettle and want to be able to do 10G batches. I set up an experiment to see how much heat was lost from the kettle when filled with 10G of mash-temperature water -- see diagram below. The kettle/water lost about 0.22C per minute which, if my thermodynamic calculations are correct, corresponds to about 550W. Making up for the kettle's heat loss seemed well-within the capabilities of a 1500W element.

I achieve my temp rise mostly by flow rate.

I achieve my temp rise mostly by flow rate.