Bryce

Active Member

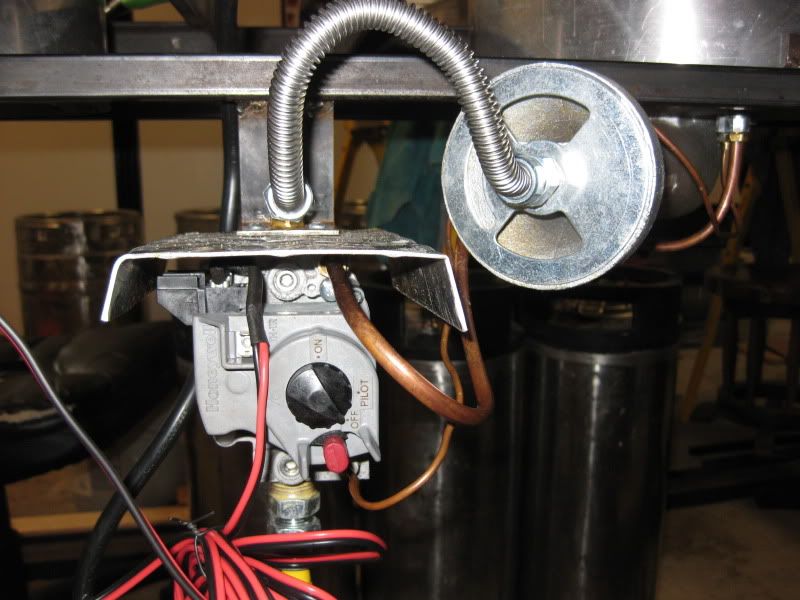

Beerthirty I'm putting together an automated HLT with a pilot using the:

Each Y8610U kit includes:

S8610U Intermittent Pilot Module.

VR8304M Dual Valve Combination Gas Control.

392431 Igniter-Sensor* (Not used for this Application you will need to purchase a Q345A1313. See Below).

394800-30 Ignition Cable.

393691 Natural to LP Gas Conversion Kit.

Wiring Harness.

393690-14 Straight Flange Kit (3/4 in.) .

Reducer adapters for gas control.

Adhesive mounting option for S8610.

Installation hardware.

Can I run 10 PSI through this? Will I need an ASCO value with it? I didn't think the Y8610U could handle high pressure. What type of regulator are you using in your setup? I would really use some help pulling these pieces together. Thanks!!!!!!

Each Y8610U kit includes:

S8610U Intermittent Pilot Module.

VR8304M Dual Valve Combination Gas Control.

392431 Igniter-Sensor* (Not used for this Application you will need to purchase a Q345A1313. See Below).

394800-30 Ignition Cable.

393691 Natural to LP Gas Conversion Kit.

Wiring Harness.

393690-14 Straight Flange Kit (3/4 in.) .

Reducer adapters for gas control.

Adhesive mounting option for S8610.

Installation hardware.

Can I run 10 PSI through this? Will I need an ASCO value with it? I didn't think the Y8610U could handle high pressure. What type of regulator are you using in your setup? I would really use some help pulling these pieces together. Thanks!!!!!!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)