Finally compelted the new brew rig after a month or so of planning and research. I wanted to keep things small and really all inclusive. So I didnt go all out w/ custom made burners but rather used a camping stive I baught from Costco as it works like a charm.

Some of the thought process was derived from many different variations I found through multiple threads on HBT.

The basic frame:

Water Manifold coming into the rig:

More process on the water source guts:

Water input/output to the stationary chiller:

Water Filtration System:

Valve Completion (From L to R - Water Filtration Valve; Flush Line Valve; Chiller Valve; Pump Flow Valve):

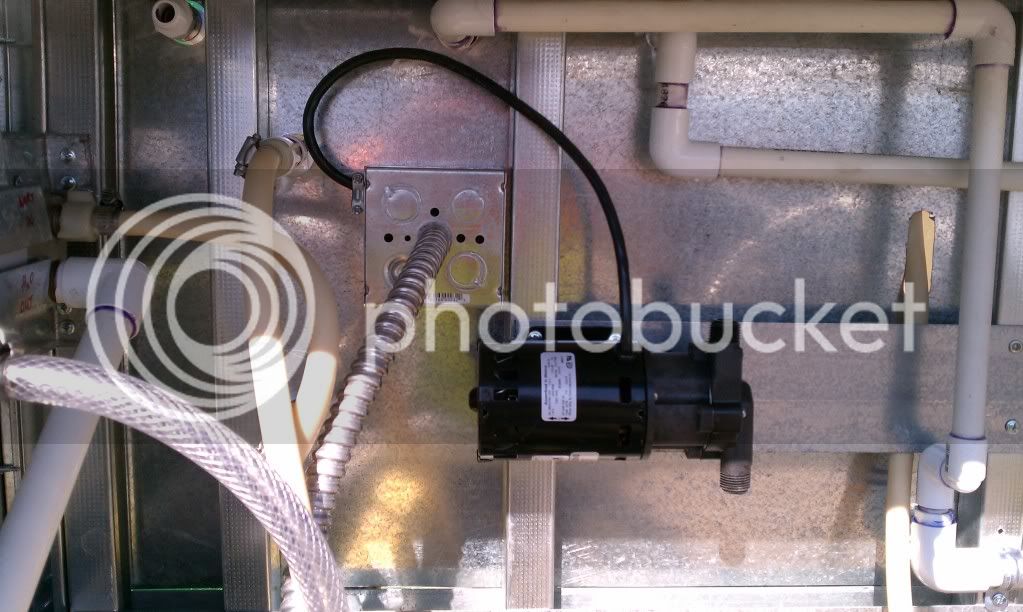

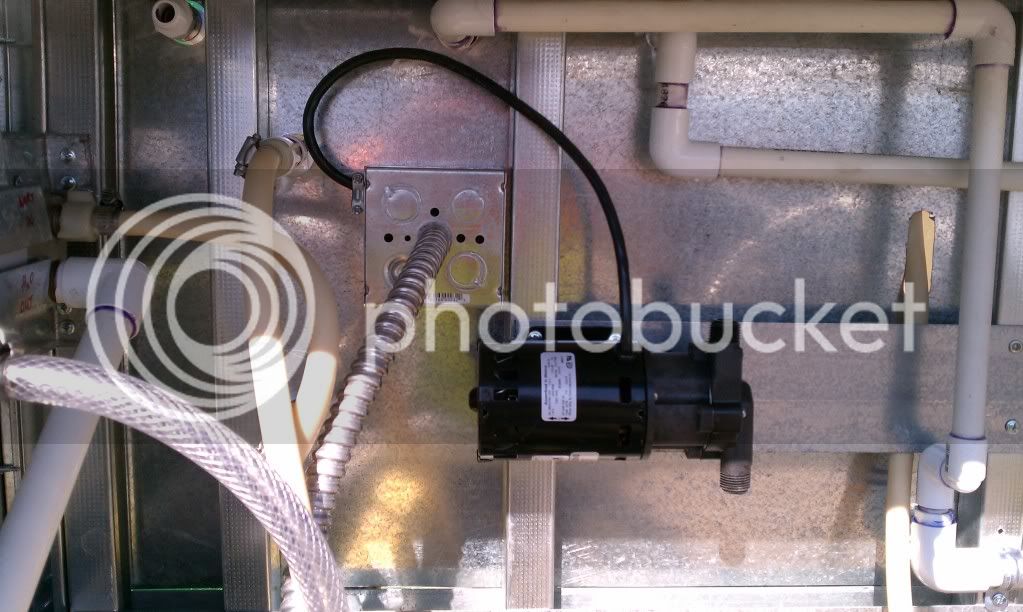

Install of the March Pump and Running of Electrical Switch:

Test Run w/ Water (Making sure there are no leaks):

Water from Filter into Kettle:

Final pics right before brewing: :rockin:

Some of the thought process was derived from many different variations I found through multiple threads on HBT.

The basic frame:

Water Manifold coming into the rig:

More process on the water source guts:

Water input/output to the stationary chiller:

Water Filtration System:

Valve Completion (From L to R - Water Filtration Valve; Flush Line Valve; Chiller Valve; Pump Flow Valve):

Install of the March Pump and Running of Electrical Switch:

Test Run w/ Water (Making sure there are no leaks):

Water from Filter into Kettle:

Final pics right before brewing: :rockin: