neomantra

Well-Known Member

Ok, I've done several AG batches now. I tried BIAB with decent success but grew tired of holding heavy bags of grain and so I bought a bazooka screen that fit into my 10g kettle to use it for batch sparging. The first time I used this I quickly realized that maintaining the mash temp for an hour was a problem. My efficiency came out to 60% or something. Then I bought the Reflectix insulation stuff I've seen mentioned here on the forums to help with insulation. This helped hold the temperature for an hour but I still think I missed my target mash temp by a few degrees, and again the efficiency was crap (~60%) yet again. So the question is, would a 146-147 temp contribute to low efficiency? That's the only thing I can think of that's not going according to plan.

More details for those who might be able to help...

I always thought the lower temps would just mean dry beer and higher fermentability. Any ideas what could be causing my problem? I'd really like to get up in to the high 70's or lower 80's for efficiency.

More details for those who might be able to help...

- I ran an iodine test and it looked to me like the conversion completed (no blue colors after mixing the iodine w/ the wort sample).

- I'm using Austin Homebrew grains that are pre-crushed

- BobbyM's no mash out double batch sparge was the technique I tried to follow

- I used BrewTarget to calculate water volumes (1.25 q/lb mash, sparge was two ~3g volumes)

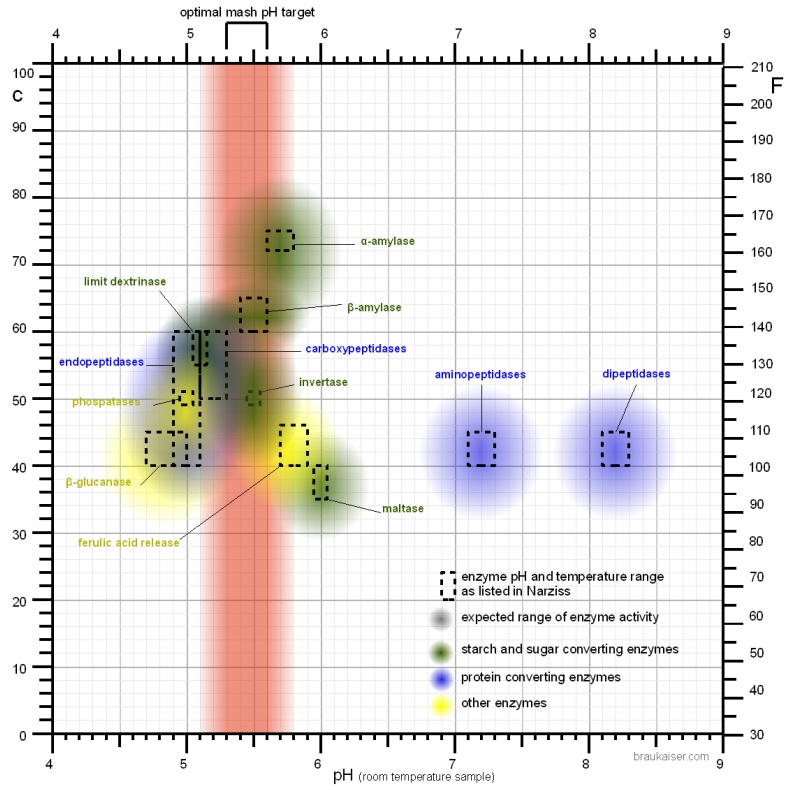

- I've tested water PH in the past with PH strips and it seemed to be ~5

- The kettle spigot is a little bit raised from the bottom. I figured out that I lose about 1.2 gallons of wort at the end of the boil if I don't try and tilt the thing at all. I'm not really sure how much I'm losing during the mash since a lot of the liquid is absorbed into grains and makes it hard to measure what gets left behind in the kettle during that part.

I always thought the lower temps would just mean dry beer and higher fermentability. Any ideas what could be causing my problem? I'd really like to get up in to the high 70's or lower 80's for efficiency.