I am mostly into the 8-10 percent alcohol imperial stouts and quickly realized, as I was designing my e-brewing system, that I couldn't fit enough grains into a keggle, to make 10 gal of beer in the style I want.

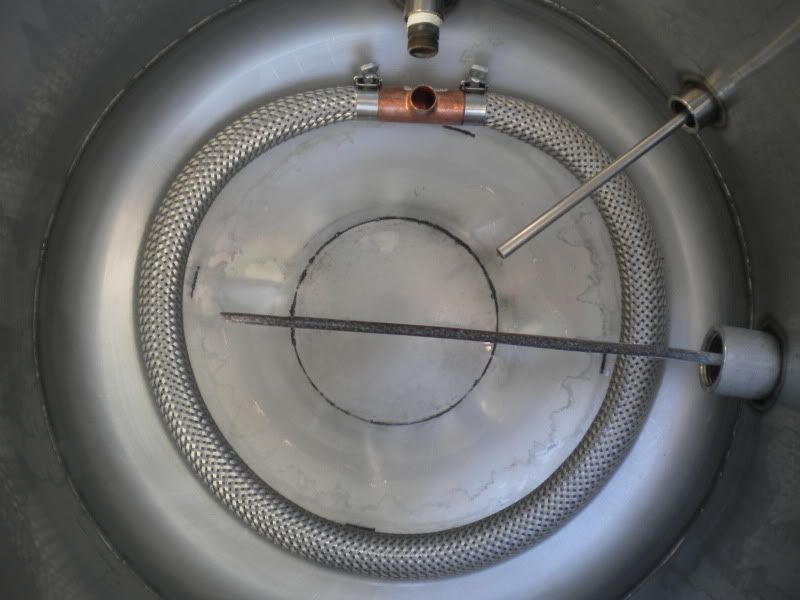

This leads me to the MLT. I have a 114L/30gal food grade barrel. I have a lid for it, however, the barrel is not insulated. The plastic is 2.2mm thick and it is really sturdy and was never previously used for anything. (The dribble in the pic is from putting my IC in there after my last batch--no big deal.)

I'm building a single-tier e-system following Kal's design. The other two vessels are keggles, one for a BK and one for a HLT with a HERMS coil. You get the idea....

So...Here are the main questions:

1) With a HERMS coil regulating my temps, do I need to insulate it?

1a) If so, what should I use to insulate it? (what doesn't get gross when exposed to liquid?)

2) What type of false bottom should I use? The diameter of the barrel is 17" but as you can see, the bottom is not flat.

3) Should I use a dip tube through the false bottom and go up and out the side?

3a) Should I mount the dump valve underneath one of the sides (lowest point inside) so the barrel kinda' hangs off my brewing stand and I can just let gravity do its thing down to my pumps?

3b) Do I need any other holes in the barrel if pump in through the lid or open top (ie: no other holes in the sides)?

4) Should I make one of those copper manifolds with drilled holes, attached to the underside of the lid, to more evenly disperse the recirculated water?

Whatever, I'm even confusing myself. Here are some pictures. I'd really appreciate any suggestions ya'll have to get this brewing party started. Thanks!

This leads me to the MLT. I have a 114L/30gal food grade barrel. I have a lid for it, however, the barrel is not insulated. The plastic is 2.2mm thick and it is really sturdy and was never previously used for anything. (The dribble in the pic is from putting my IC in there after my last batch--no big deal.)

I'm building a single-tier e-system following Kal's design. The other two vessels are keggles, one for a BK and one for a HLT with a HERMS coil. You get the idea....

So...Here are the main questions:

1) With a HERMS coil regulating my temps, do I need to insulate it?

1a) If so, what should I use to insulate it? (what doesn't get gross when exposed to liquid?)

2) What type of false bottom should I use? The diameter of the barrel is 17" but as you can see, the bottom is not flat.

3) Should I use a dip tube through the false bottom and go up and out the side?

3a) Should I mount the dump valve underneath one of the sides (lowest point inside) so the barrel kinda' hangs off my brewing stand and I can just let gravity do its thing down to my pumps?

3b) Do I need any other holes in the barrel if pump in through the lid or open top (ie: no other holes in the sides)?

4) Should I make one of those copper manifolds with drilled holes, attached to the underside of the lid, to more evenly disperse the recirculated water?

Whatever, I'm even confusing myself. Here are some pictures. I'd really appreciate any suggestions ya'll have to get this brewing party started. Thanks!