I am actually wondering how someone could fill their own 5# off of their own 25#? I know paintball places do it all the time. This alone would make me happy and save me a ton of trouble and cost.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How about a CO2 Capture system?

- Thread starter Sir Humpsalot

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Nov 26, 2006

- Messages

- 3,996

- Reaction score

- 94

Nice find wortmonger, but it's about 3x what I was thinking of spending.

Yeah, me too.

The beer staying at serving pressure is a tough one to think through since the regulator won't work at such low back pressures.

The beer staying at serving pressure is a tough one to think through since the regulator won't work at such low back pressures.

Ohhh, I may have an even smaller solution to my problems (well if I continue buying CO2 in bulk). Check out the refill stuff.

OK, how bout this for lower back pressure CO2 regulation.

http://cgi.ebay.com/Miniature-Secondary-CO2-Regulator-for-beer-paintbrush_W0QQitemZ150195446351QQihZ005QQcategoryZ38172QQssPageNameZWDVWQQrdZ1QQcmdZViewItem

http://cgi.ebay.com/Miniature-Secondary-CO2-Regulator-for-beer-paintbrush_W0QQitemZ150195446351QQihZ005QQcategoryZ38172QQssPageNameZWDVWQQrdZ1QQcmdZViewItem

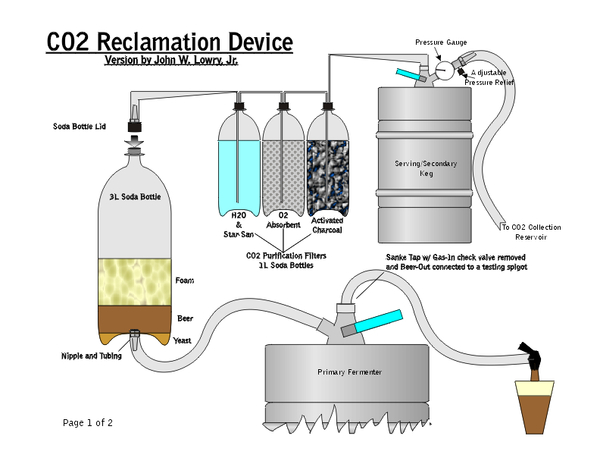

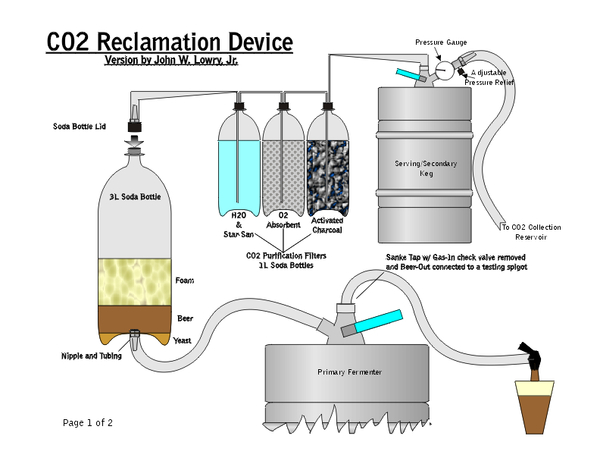

Keep in mind you'll have to collect your CO2 in a collapsable container like a huge balloon. Why? Well, if you collect it in a 1/2barrel keg, there would be no way to collect all the CO2 into the vaccum line of the compressor unless it could pull a vaccum equal to the output pressure (no way).

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

- Joined

- Nov 26, 2006

- Messages

- 3,996

- Reaction score

- 94

I was about to say mini airbrush things seem like a good fit...

- Joined

- Nov 26, 2006

- Messages

- 3,996

- Reaction score

- 94

Bobby_M said:Keep in mind you'll have to collect your CO2 in a collapsable container like a huge balloon. Why? Well, if you collect it in a 1/2barrel keg, there would be no way to collect all the CO2 into the vaccum line of the compressor unless it could pull a vaccum equal to the output pressure (no way).

see my post about the double carboy setup. Use water/starsan as a medium for "expanding and collapsing" the volume of a rigid system, for example, one using carboys.

Ahh haa!! See that is good to know. I was hoping everything after the spunding valve wouldn't have to be controlled, just collected.

- Joined

- Nov 26, 2006

- Messages

- 3,996

- Reaction score

- 94

In fact, if there were a way of preventing CO2 from dissolving in water, we could use about a gallon of water in a tube with a nearly 2-inch cross-section, about 10 feet high, to create 8 pounds of pressure on the co2 in a carboy... (231 cu inches in a gallon, a gallon of water equals 8.33 lbs) I didn't actually do any measurements or math, but that's my rough guess of what it would take...

You know what though? I'm tired of looking for a simple hydraulic device... I'm thinking I could make one... I'm going to go search the net for parts....

You know what though? I'm tired of looking for a simple hydraulic device... I'm thinking I could make one... I'm going to go search the net for parts....

Philip1993

Well-Known Member

- Joined

- Jul 5, 2007

- Messages

- 1,644

- Reaction score

- 19

8# of h2o would require a one square inch piston (1.13in diameter) to create 8psi. A 2 inch diameter piston would would generate a mere 2.65psi.

- Joined

- Nov 26, 2006

- Messages

- 3,996

- Reaction score

- 94

Ok, forget the parts list, it's going to be quite a search, but basically, here's what you need.

Two pistons housed in a cylinder, each with a port. On one side, you have, for example, a 3 square inch piston. On the other side, you have a one square inch piston.

You use a low pressure pump, like one from a spray gun, into the 3 inch diameter piston. at 50 psi, you have 150 pounds of force.

Now, on the 1 inch side, you introduce CO2. where 1/3 of the volume gets squeezed up to 150 psi. Open the valve on the tank, put the gas in, close the valve, and release the pressure.

Now, just find a way to automate this procedure safely....

Two pistons housed in a cylinder, each with a port. On one side, you have, for example, a 3 square inch piston. On the other side, you have a one square inch piston.

You use a low pressure pump, like one from a spray gun, into the 3 inch diameter piston. at 50 psi, you have 150 pounds of force.

Now, on the 1 inch side, you introduce CO2. where 1/3 of the volume gets squeezed up to 150 psi. Open the valve on the tank, put the gas in, close the valve, and release the pressure.

Now, just find a way to automate this procedure safely....

You could get around many of the problems by using a high pressure portable air compressor & putting it inside of your collection balloon. (Maybe one of those balloons used for flying meteorological instruments.) You could control the compressor with a micro-switch triggered by the balloon collapsing.

Nwcw2001

Well-Known Member

wortmonger said:I am actually wondering how someone could fill their own 5# off of their own 25#? I know paintball places do it all the time. This alone would make me happy and save me a ton of trouble and cost.

Yes that is possible. At the brewery I worked at before I move to Colorado, I needed to fill my buddy's 25# CO2 tank after emptying it after 2 years of use. The Brewer had what he called a "pigtail" and it was a tube with a screw end, like on your regulator, on each end. Hook up both tanks and turn the gas on the full one, open the empty one and it PARTIALLY fills. At this point you turn off the valves and disconnect the partial tank. Open the valve on the partial to drain the tank quickly (but not full bore or the gas inside will turn to dry ice) and chill it down, because a warm tank will not fill all the way. Weigh the empty tank to find out how much the tank weighs. Reconnect the tanks and repeat the filling direction, when the hissing stops it will be full. Now weigh the tank to ensure it is holding the correct poundage! IF it is more than the tank should be (ie: 6#'s in a 5# tank) bleed it off or you will blow the safety valve.

- Joined

- Nov 26, 2006

- Messages

- 3,996

- Reaction score

- 94

david_42 said:You could get around many of the problems by using a high pressure portable air compressor & putting it inside of your collection balloon. (Maybe one of those balloons used for flying meteorological instruments.) You could control the compressor with a micro-switch triggered by the balloon collapsing.

True.. but I would prefer one that's pneumatic-based, rather than electrically based. I am afraid of what would happen when using an electrical device in an oxygen-free environment. I'm not saying whether or not it's dangerous, but it's just something I haven't ever thought about and I'm rather unsure of where to start...

There's really nothing to fear. Fire needs oxygen. CO2 puts fires out. Electrical devices don't need oxygen to run. I think you're good to go!Sir Humpsalot said:I am afraid of what would happen when using an electrical device in an oxygen-free environment.

Philip1993

Well-Known Member

- Joined

- Jul 5, 2007

- Messages

- 1,644

- Reaction score

- 19

wortmonger said:I am actually wondering how someone could fill their own 5# off of their own 25#? I know paintball places do it all the time. This alone would make me happy and save me a ton of trouble and cost.

I have a simple adapter that I use to fill 1# propane cylinders off a 30# tank. And my rocket buddies fill N2O cylinders of a bulk tank. In both cases, the supply is inverted to flow liquid into the destination. Stop filling when the target weighs the proper weight. AS already indicated, overfilling can result in the burst disk rupturing when the tank reaches ambient temps.

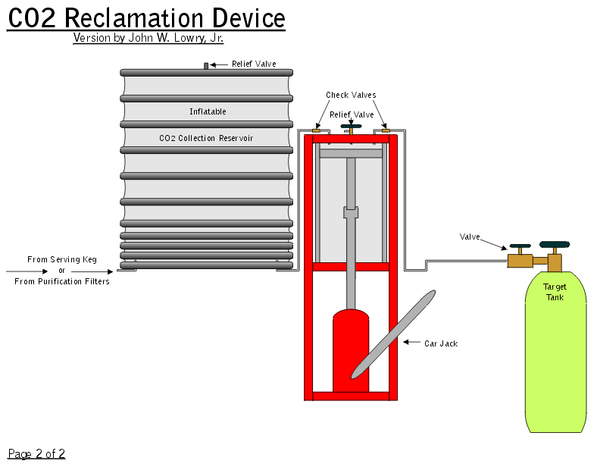

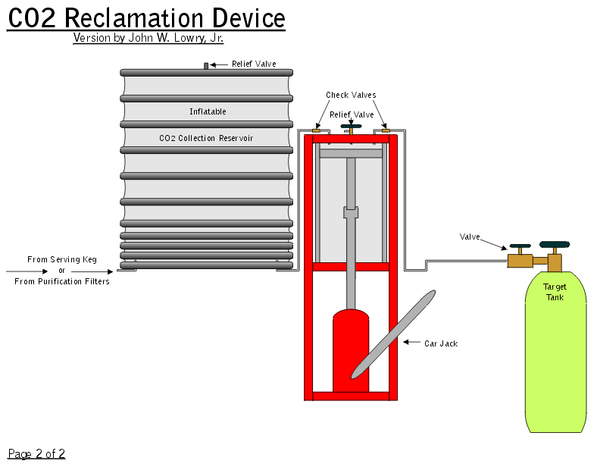

Would a single piston and "one side closed" cylinder work? What if the cylinder was plumbed with two one-way valves (one only introducing CO2 from your collection device, and the other leading to the target CO2 tanks plumbing and connections), and a manual relief valve to purge the system the first time. The piston and closed-off cylinder could be attached to a car jack by surrounding them both with a heavier gauge metal welding both permanantly together opposing each others force. How would that work for filling the tank over a couple of times jacking?

Just found this, I need a air compressor!!!

Just found this, I need a air compressor!!!

macs

Well-Known Member

- Joined

- Sep 6, 2007

- Messages

- 138

- Reaction score

- 2

Sir Humpsalot said:True.. but I would prefer one that's pneumatic-based, rather than electrically based. I am afraid of what would happen when using an electrical device in an oxygen-free environment. I'm not saying whether or not it's dangerous, but it's just something I haven't ever thought about and I'm rather unsure of where to start...

I arc weld with CO2 as the shielding gas. If it's fairly pure CO2 there is no danger.

macs

Well-Known Member

- Joined

- Sep 6, 2007

- Messages

- 138

- Reaction score

- 2

wortmonger said:Would a single piston and "one side closed" cylinder work? What if the cylinder was plumbed with two one-way valves (one only introducing CO2 from your collection device, and the other leading to the target CO2 tanks plumbing and connections), and a manual relief valve to purge the system the first time. The piston and closed-off cylinder could be attached to a car jack by surrounding them both with a heavier gauge metal welding both permanantly together opposing each others force. How would that work for filling the tank over a couple of times jacking?

Just found this, I need a air compressor!!!

I like that huge guage on that small tank!! What pressure scale does it cover??

Found this on CO2 recovery. Beer chemists.

http://www.asbcnet.org/resources/CO2.html

More than half-way down it talks about the steps in CO2 purification. It says there are volatiles in fermentation gasses, and I am assuming these are mostly water soluble? They have a the same type of filter train that OldFart had on his initial runs.

http://www.asbcnet.org/resources/CO2.html

More than half-way down it talks about the steps in CO2 purification. It says there are volatiles in fermentation gasses, and I am assuming these are mostly water soluble? They have a the same type of filter train that OldFart had on his initial runs.

Well, it's probably something like 1000-5000psi. Tanks are usually hot filled to 4000psi but cavers have been known to push them to back splitting pressures like 6000. Crazy guys they are.

By the way, have you guys realized enough obstacles in this project to throw the towel in or what? I'm all for basement engineering but you do realize for the amount of thought you've put into this, you could have begged for change on the street and taken the profit to have a 20lb tank filled.

Bobby_M said:By the way, have you guys realized enough obstacles in this project to throw the towel in or what? I'm all for basement engineering but you do realize for the amount of thought you've put into this, you could have begged for change on the street and taken the profit to have a 20lb tank filled.

Too early to call. I put the overs @125 posts.

I like working it out in my head and on here. I am probably just going to learn how to refill my own 5# bottle to half-way so it is a little more safe for me, and just refill when needed to serve only. I can then keep my big bottle in my brewery to purge and transfer things as needed. The only way I would actually build anything is if it could be completely self collecting (like a collapsible ducting that grew to the ceiling) and hand operated to pressure fill the 5# tank (like the jack and cylinder I spoke of earlier and the other ideas). Past that, if it were ran off an already bought air compressor I could do that too, but it really isn't worth the hassle just fun to have the hassle to work in my head and on paper. That low back-pressure CO2 regulator really gave me some ideas of use once in the 5#, just how to get in there with enough juice to power through at least a single keg before needing a refill.

Somewhat related. I know david_42 recycles the CO2 when he makes seltzer water using street water pressure. Maybe he'll chime in on that.

I think the practical usage for collected CO2 is simply purging O2 out of say your secondary or keg. It can easily done by fitting a mylar balloon to a nipple on a capped blowoff vessel. Then you can attach a long dip tube, insert to the bottom of your carboy and squeeze the balloon. This idea of pressuring to 60psi into a tank is just way out there.

macs

Well-Known Member

- Joined

- Sep 6, 2007

- Messages

- 138

- Reaction score

- 2

Bobby_M said:Well, it's probably something like 1000-5000psi. Tanks are usually hot filled to 4000psi but cavers have been known to push them to back splitting pressures like 6000. Crazy guys they are.

Wow!! That's wickedly high! That's like strapping rockets on your back. I wonder if the compressors they use for compressing air to those levels are the same ones used for CO2?

I doubt it. CO2 needs less than 1000psi to liquify. Here are some USED scuba compressors for only $8500.

http://www.northshorecompressor.com/used-compressors/used-compressors.html

http://www.northshorecompressor.com/used-compressors/used-compressors.html

OK, I know this probably won't work, but....

Similar threads

- Replies

- 1

- Views

- 2K

- Replies

- 0

- Views

- 892

- Replies

- 7

- Views

- 2K

- Replies

- 14

- Views

- 770