GearBeer

Well-Known Member

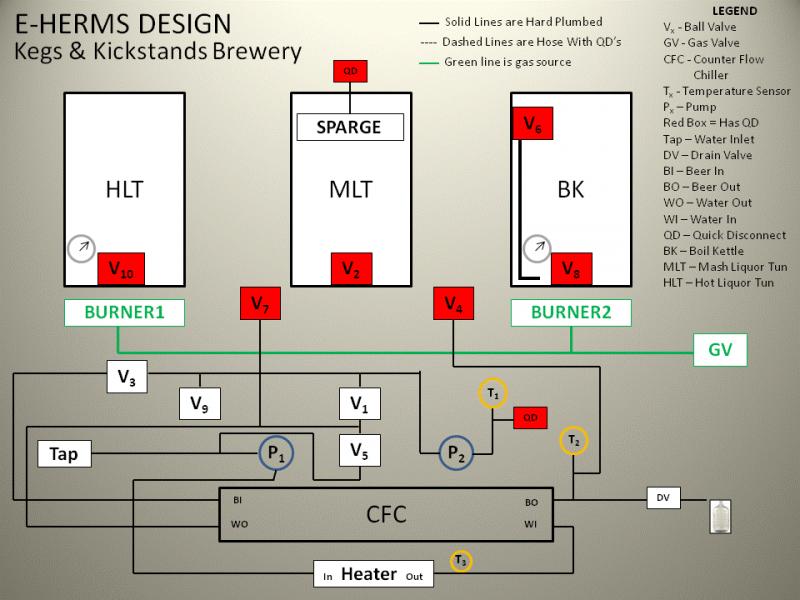

Harley03 and I were spurred into discussion by blackheart's thread. We thought we could develop a design that used fewer valves. I sketched something up and after going back and forth several times and getting additional input from PunchDrunk we managed to trim two valves (which I proceeded to add back for additional capabilities).

Notable design features:

I sketched out every function the system would experience, including fly sparging, batch sparging, capturing second runnings, sanitization and cleaning. If you want to see everything I've done, you may prefer to look through my HERMS Photobucket album.

Note: I am omitting some slides, so some of the directions in the upper right corner will not be continuous. Yes, I realize this.

Water in the HLT and HERMS Tank are heated to strike and control (several degrees above the mash)temperatures, respectively. When both reach their set points the strike water is pumped into the MLT.

The sparge assembly is removed and the grain is added and mixed.

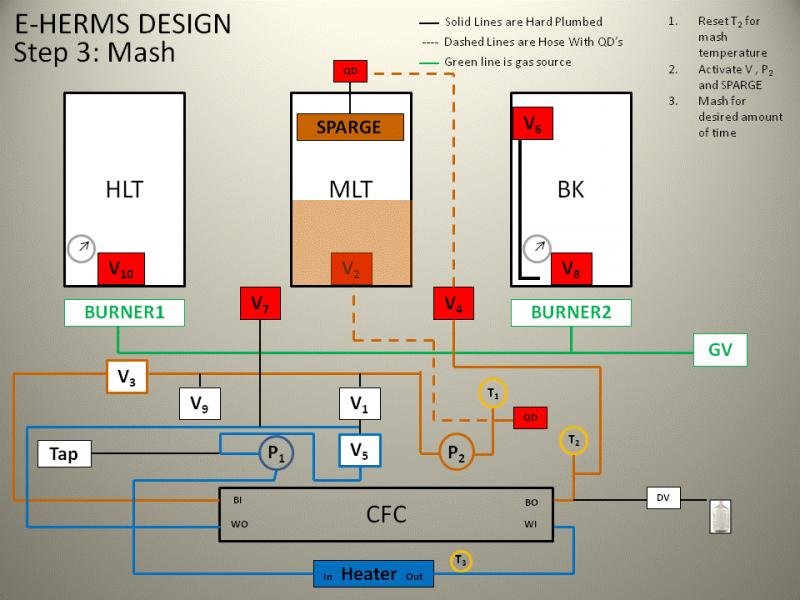

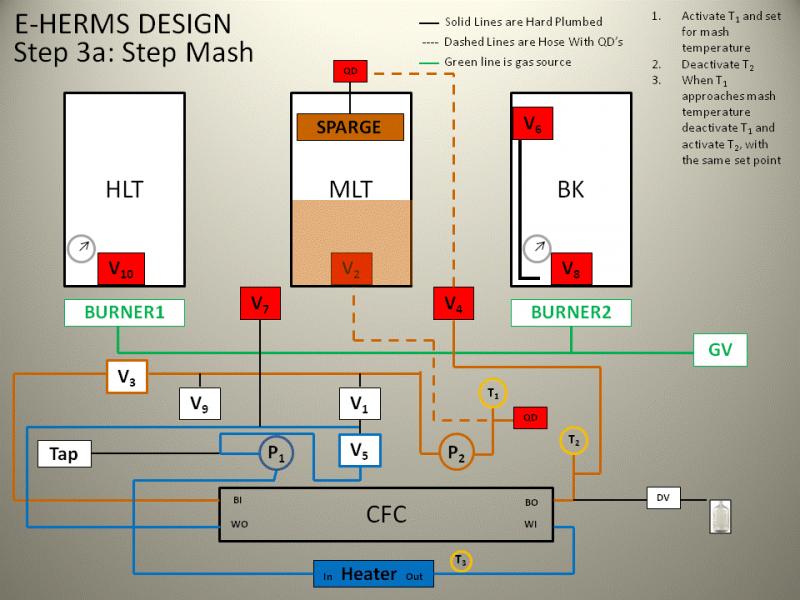

The sparge assembly is replaced and partially submerged, then the valves are reconfigured to recirculate the mash. The recirculation will be used to perform a mash out.

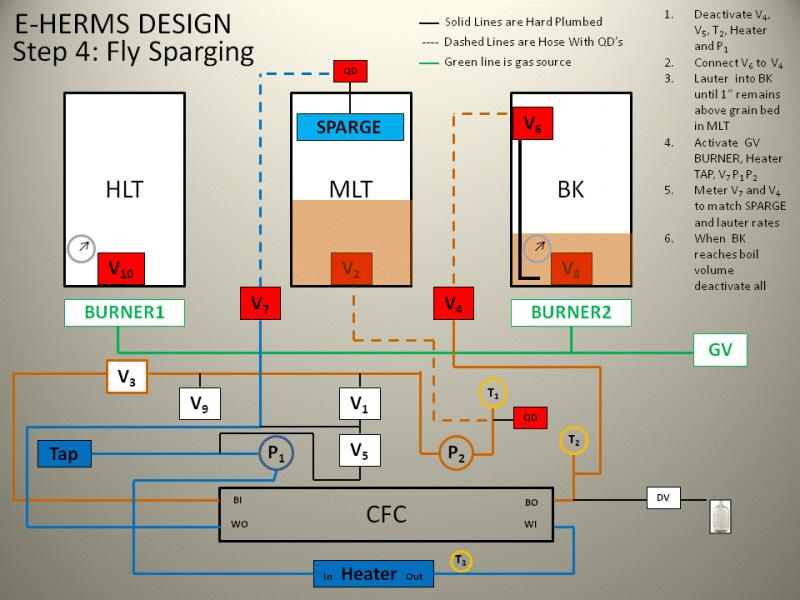

The fully converted mash is pumped into the boil kettle. When the wort in the MLT is approximately one inch above the grain bed the first pump resumes and the grain bed is fly sparged until the desired volume is reached.

The omitted slide runs boiling water through the system from the HLT.

Boiling wort is recirculated to sanitize the CFC and piping that will carry the wort to the fermenter.

The wort recirculation continues and whirlpools the hot break and hop material away from the pickup tube. As whirlpooling ends cold water begins to flow through the counterflow. The hot exhaust water from the counterflow is captured in the HLT for cleaning. A temperature sensor controls the solenoid valve, which routes cooled wort into the fermenter.

The omitted slides push hot water through the system.

Hot water from the HLT and HERMS Tank is pumped through the system to expel any captured sugars. When all of the water has been expelled, the system is left open to dry.

Notable design features:

- Separte HERMS tank

- Faster temperature response

- Control temperature independent of sparge water temperature

- MLT made from inverted keg

- Central drain location

- Easy cleaning

- Escape valve

- Exit point for hop matter and hot break dislodged during cleaning before CFC

- Exit point for second runnings

- Sparge Arm with vertical copper piping and silicone flex hose

- Hard copper piping permits adjustability without separate support

- Vertical adjustability allows sparge arm to double for recirculation

I sketched out every function the system would experience, including fly sparging, batch sparging, capturing second runnings, sanitization and cleaning. If you want to see everything I've done, you may prefer to look through my HERMS Photobucket album.

Note: I am omitting some slides, so some of the directions in the upper right corner will not be continuous. Yes, I realize this.

Water in the HLT and HERMS Tank are heated to strike and control (several degrees above the mash)temperatures, respectively. When both reach their set points the strike water is pumped into the MLT.

The sparge assembly is removed and the grain is added and mixed.

The sparge assembly is replaced and partially submerged, then the valves are reconfigured to recirculate the mash. The recirculation will be used to perform a mash out.

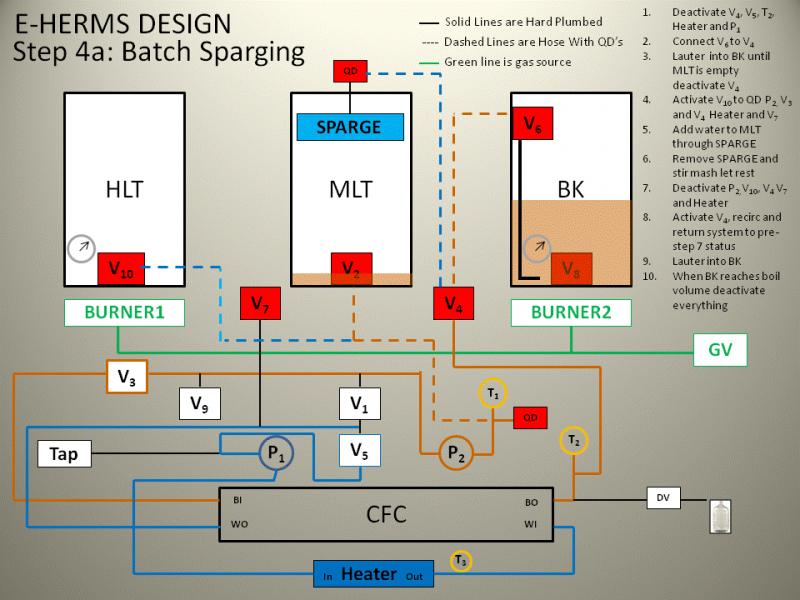

The fully converted mash is pumped into the boil kettle. When the wort in the MLT is approximately one inch above the grain bed the first pump resumes and the grain bed is fly sparged until the desired volume is reached.

The omitted slide runs boiling water through the system from the HLT.

Boiling wort is recirculated to sanitize the CFC and piping that will carry the wort to the fermenter.

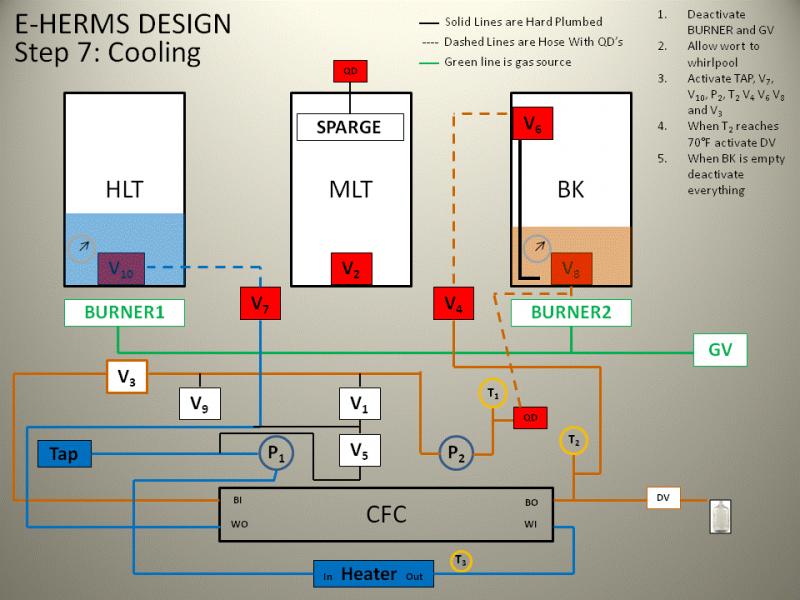

The wort recirculation continues and whirlpools the hot break and hop material away from the pickup tube. As whirlpooling ends cold water begins to flow through the counterflow. The hot exhaust water from the counterflow is captured in the HLT for cleaning. A temperature sensor controls the solenoid valve, which routes cooled wort into the fermenter.

The omitted slides push hot water through the system.

Hot water from the HLT and HERMS Tank is pumped through the system to expel any captured sugars. When all of the water has been expelled, the system is left open to dry.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)