BreakingBarley

I should brew soon...

- Joined

- Nov 7, 2020

- Messages

- 13

- Reaction score

- 4

Hi all,

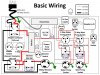

I'm finally coming around to electric brewing and am starting off with a 3-vessel E-HERMS setup wiith the following features:

-20 Gal HLT, 5500W 240v element, HERMS coil

-SS Brewtech insulated MLT, no direct heat

-Direct fire BK

-2 pumps, TC everywhere feasible

-CraftBeerPi controlled element & pumps w/manual pump override switches

-5-10 gal batches typical, surge to 15 gal periodically

With that in mind, how does my wiring & overall setup look? Any protections missing or unintuitive wiring?

Thanks in advance!

-BB

I'm finally coming around to electric brewing and am starting off with a 3-vessel E-HERMS setup wiith the following features:

-20 Gal HLT, 5500W 240v element, HERMS coil

-SS Brewtech insulated MLT, no direct heat

-Direct fire BK

-2 pumps, TC everywhere feasible

-CraftBeerPi controlled element & pumps w/manual pump override switches

-5-10 gal batches typical, surge to 15 gal periodically

With that in mind, how does my wiring & overall setup look? Any protections missing or unintuitive wiring?

Thanks in advance!

-BB