dukes7779

Well-Known Member

- Joined

- Jun 9, 2011

- Messages

- 205

- Reaction score

- 0

Hey everyone!

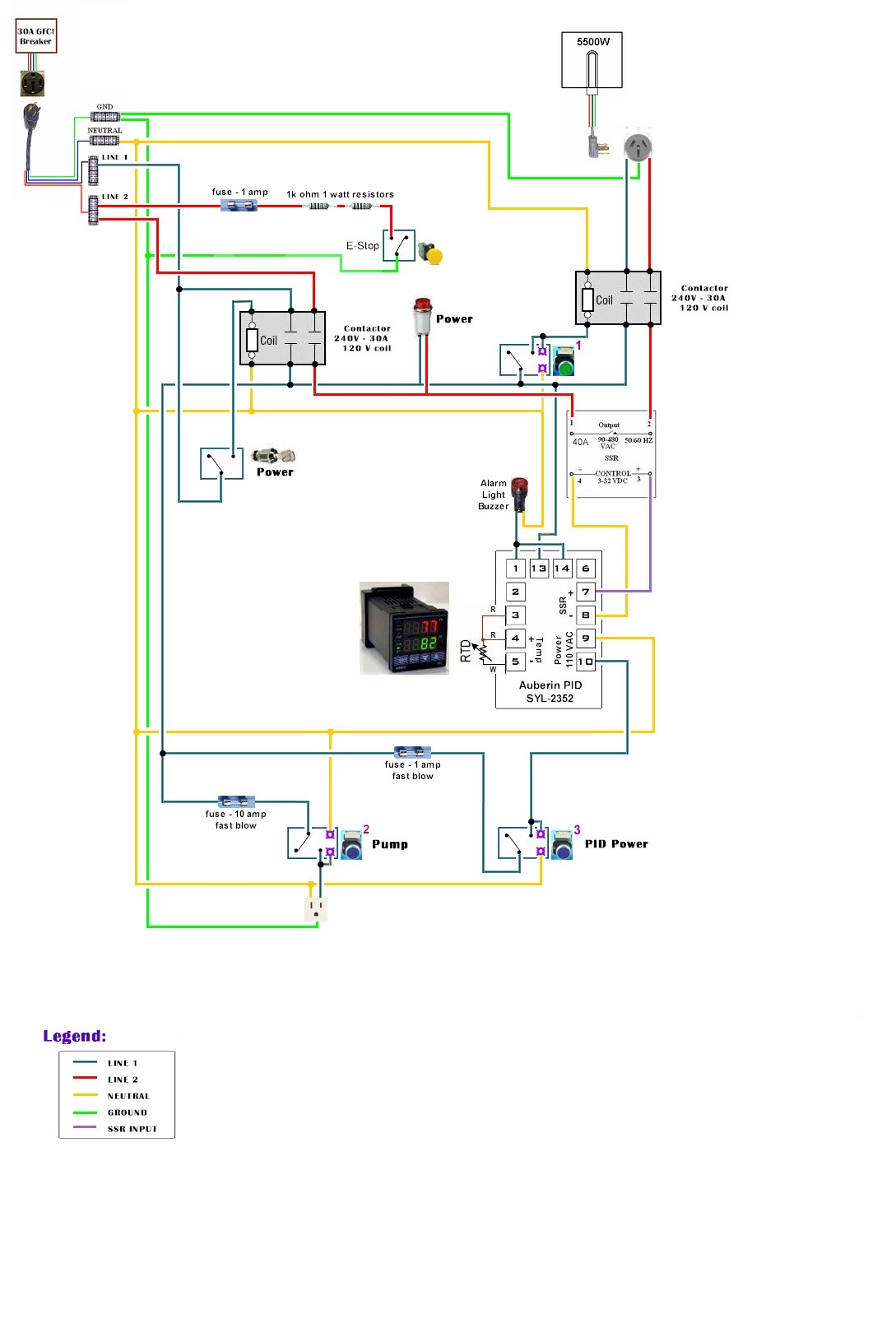

The following pics are my simple set up and one of P-Js wiring diagrams. Single 5500w element in the BK. There is no on/off switch with a key (ala Kal's) in the diagram and I would like to add one to turn the control panel on and off. Where in this diagram would I do that, please? Wanting a on/off switch (not keyed) for the pump as well.

Also, wanted to make sure the diagram I chose matches what I want to do with my set up.

Thanks!!

The following pics are my simple set up and one of P-Js wiring diagrams. Single 5500w element in the BK. There is no on/off switch with a key (ala Kal's) in the diagram and I would like to add one to turn the control panel on and off. Where in this diagram would I do that, please? Wanting a on/off switch (not keyed) for the pump as well.

Also, wanted to make sure the diagram I chose matches what I want to do with my set up.

Thanks!!