Beer Viking

Beer Lover

Hey everyone,

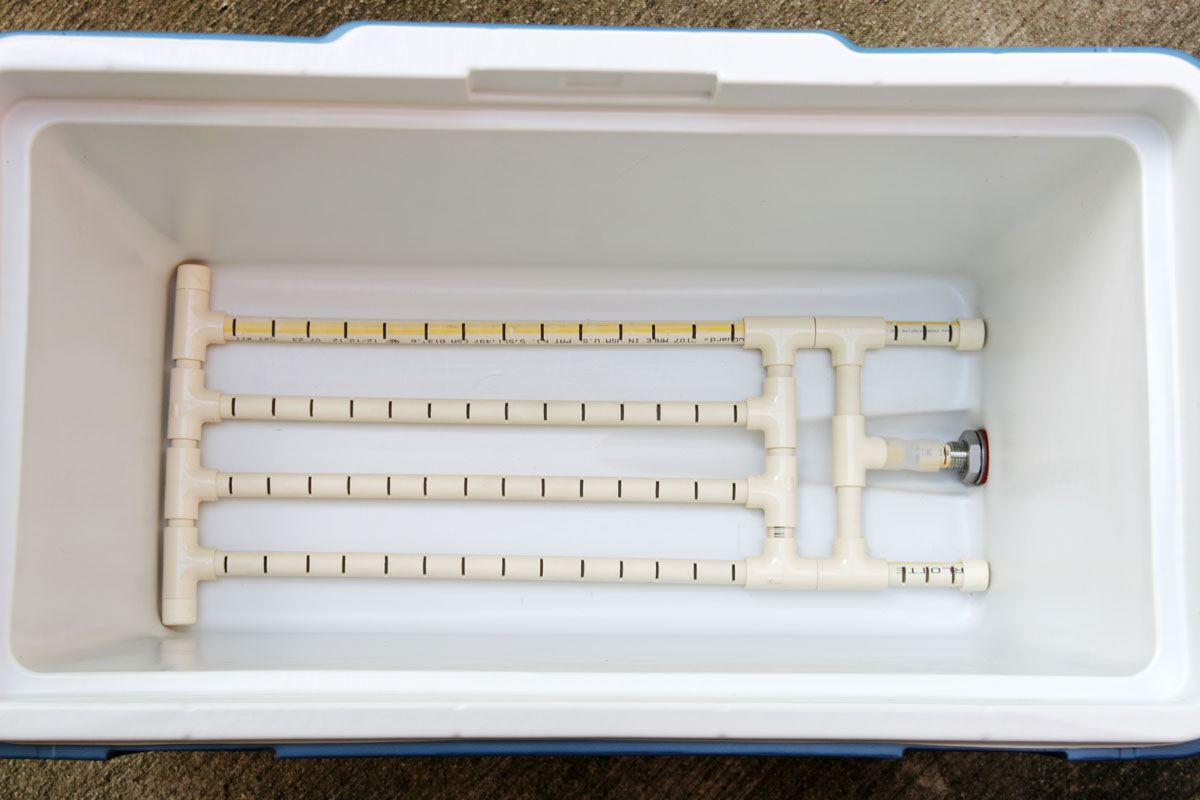

I've made beer from beer kits and I want to start making it from scratch by making the wort myself. In a previous thread I can't find now someone said when you buy the malt you have to condition it in some sort of insulated cooler before you boil it with hops to make the wort. Can someone please explain to me what I need to do with the malt before it gets boiled? A lot of the bulk malt looks like it has already been malted so if that is the case would it just be good to go?

Thanks a lot everyone!

Cheers!

I've made beer from beer kits and I want to start making it from scratch by making the wort myself. In a previous thread I can't find now someone said when you buy the malt you have to condition it in some sort of insulated cooler before you boil it with hops to make the wort. Can someone please explain to me what I need to do with the malt before it gets boiled? A lot of the bulk malt looks like it has already been malted so if that is the case would it just be good to go?

Thanks a lot everyone!

Cheers!