Yes, I searched and got conflicting information.

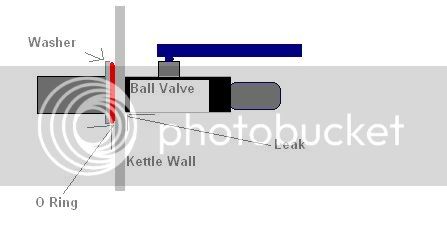

I am installing a spigot into my new brew kettle. Got that slight leak from the bottom part of the valve where it meets the pan. I've read that my back might be too tight, I've read to tighten it more.

I'm trying a small boil now to see if heat fixes the problem.

Who has sucessfully stopped this sort of leak and how did you do it (besides welding the fitting on )?

)?

Thanks in Advance,

McKBrew

I am installing a spigot into my new brew kettle. Got that slight leak from the bottom part of the valve where it meets the pan. I've read that my back might be too tight, I've read to tighten it more.

I'm trying a small boil now to see if heat fixes the problem.

Who has sucessfully stopped this sort of leak and how did you do it (besides welding the fitting on

Thanks in Advance,

McKBrew