Carolina_Matt

Well-Known Member

- Joined

- Jan 24, 2018

- Messages

- 482

- Reaction score

- 255

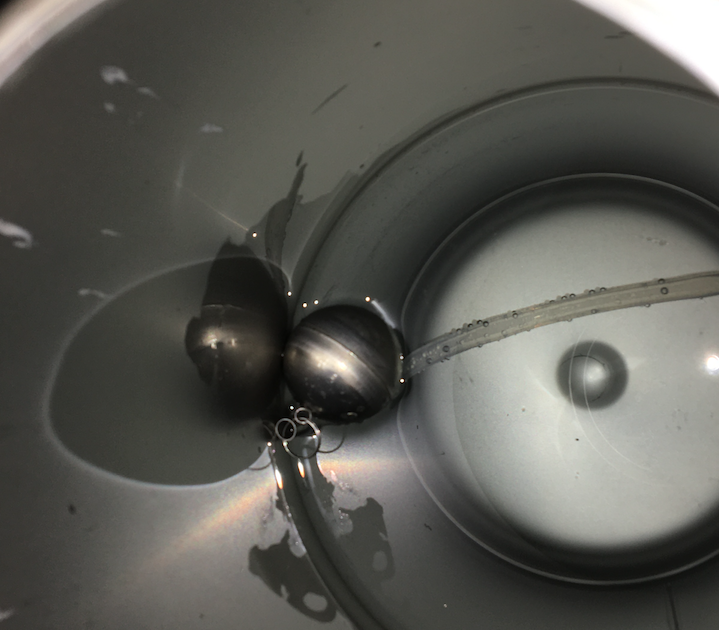

FYI, I saw this at Morebeer today and ordered 3 to ferment and serve in the same keg. Not sure if this should be in the Equipment, Kegging or Fermentation forum.

This looks like the Fermentasaurus version, but it comes with a metal dip tube and they say it has a better silicone tubing. It also looks similar to the Top Draw from Williams, but they've been out of stock for most of the last few months. So if you're looking for a Floating Dip Tube, there's another option out there. As of now, it's $17.99.

https://www.morebeer.com/products/floating-dip-tube-1.html

This looks like the Fermentasaurus version, but it comes with a metal dip tube and they say it has a better silicone tubing. It also looks similar to the Top Draw from Williams, but they've been out of stock for most of the last few months. So if you're looking for a Floating Dip Tube, there's another option out there. As of now, it's $17.99.

https://www.morebeer.com/products/floating-dip-tube-1.html