roncruiser

Well-Known Member

My local Home Depot has a Frigidaire FFTR1814QW0 on sale that's at a very good price. The sale is for this weekend only.

I want to make sure I can re-wire the fridge before pulling the trigger. I wanted to check in with some of the experts here on the forum first to make sure it can be done.

I'm sure I have access to all the wires. That shouldn't be a problem.

Here's what I would like to do:

*Control the temp in the top freezer and use it to store bottles at ~50F.

*Use the bottom fridge section as a fermentation chamber.

My first question is which wires would I need to access first to control the compressor?

With control of the compressor, I can keep the freezer section at a stable ~50F. My first thought is to use the STC-1000 to control the temp in the freezer section.

Then use another STC-1000 to control the temp in the fridge section. I believe a fan moves cool air from the freezer to the fridge to maintain fridge temp. By controlling this fan,

I can then maintain the fridge at fermenting temps greater than 50F... in theory. Preferably around 65-70F for DIPA's.

Let me know what your thoughts.

Thanks.

Ron

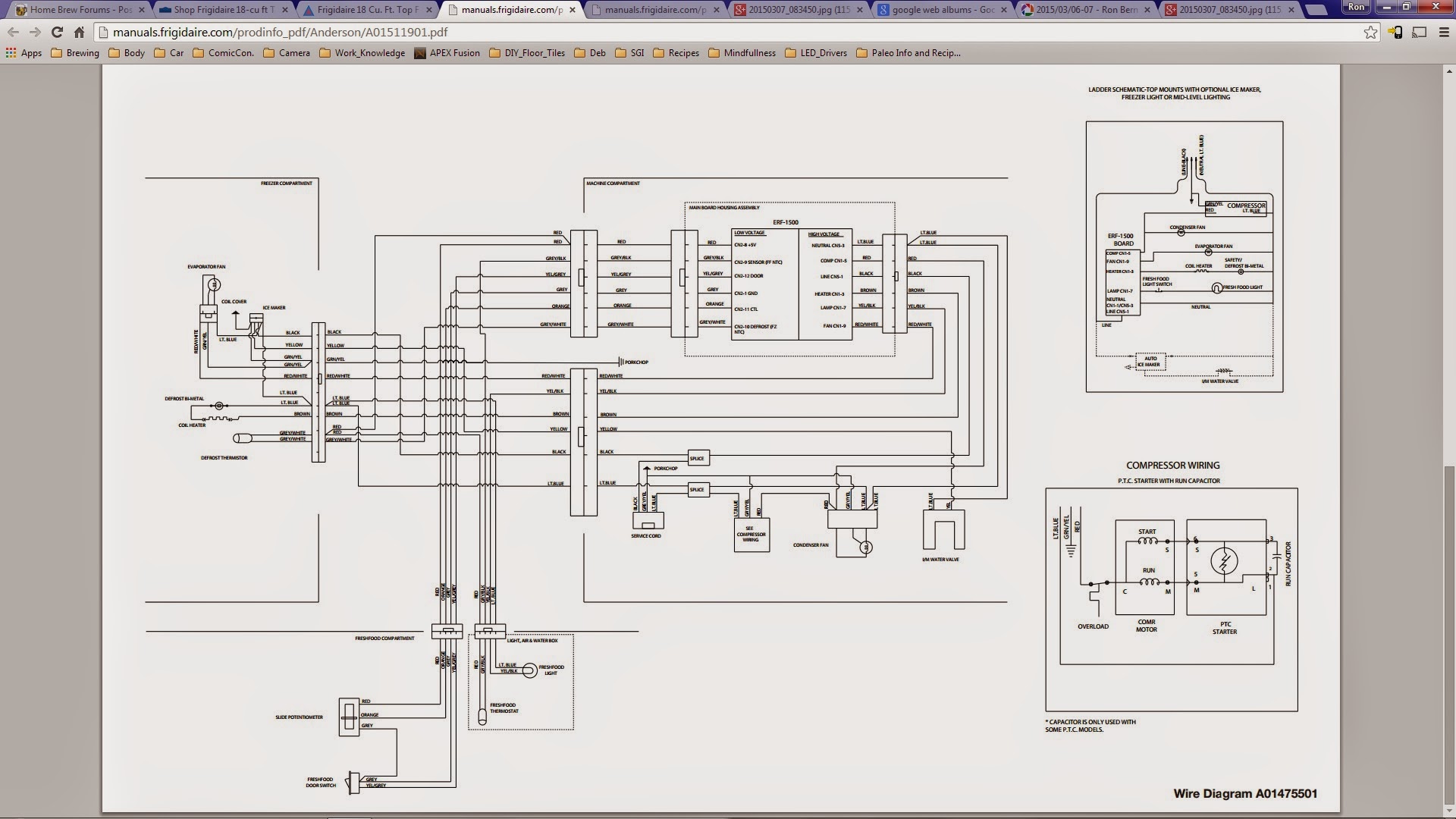

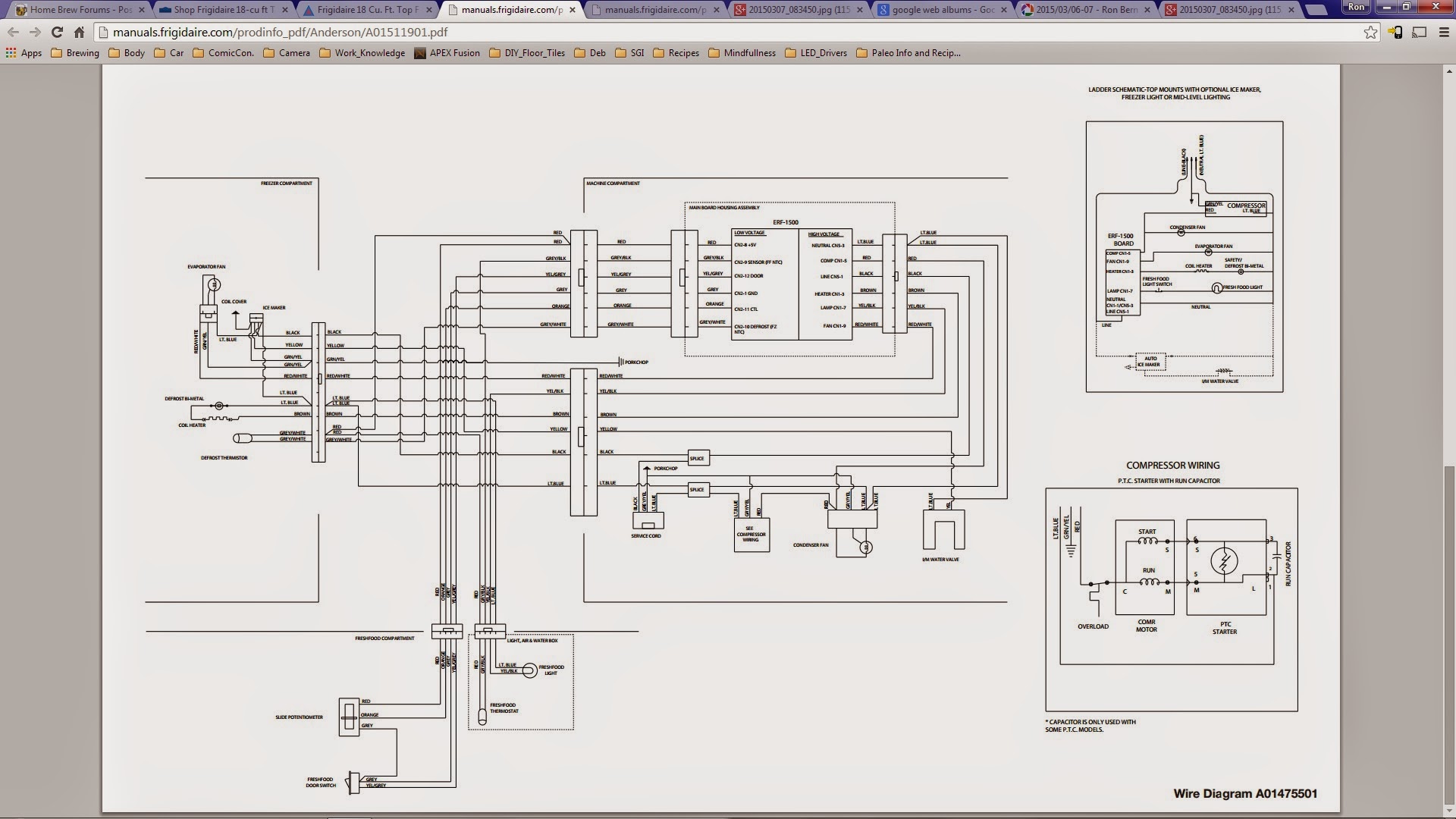

I have the schematic here:

http://manuals.frigidaire.com/prodinfo_pdf/Anderson/A01511901.pdf

Schematic below (The URL above provides a better view of the schematic):

It's a nice freezer/fridge setup. The price is almost to good to pass up.

The fridge section on top of the clear shelves measure: 18 deep x 25 wide x 28-30 high.

The freezer section measures 14 deep x 23 wide x 14 high. High enough to store bottles upright!

For future reference:

https://www.homebrewtalk.com/f252/top-freezer-roper-fridge-fermentation-chamber-223499/

I want to make sure I can re-wire the fridge before pulling the trigger. I wanted to check in with some of the experts here on the forum first to make sure it can be done.

I'm sure I have access to all the wires. That shouldn't be a problem.

Here's what I would like to do:

*Control the temp in the top freezer and use it to store bottles at ~50F.

*Use the bottom fridge section as a fermentation chamber.

My first question is which wires would I need to access first to control the compressor?

With control of the compressor, I can keep the freezer section at a stable ~50F. My first thought is to use the STC-1000 to control the temp in the freezer section.

Then use another STC-1000 to control the temp in the fridge section. I believe a fan moves cool air from the freezer to the fridge to maintain fridge temp. By controlling this fan,

I can then maintain the fridge at fermenting temps greater than 50F... in theory. Preferably around 65-70F for DIPA's.

Let me know what your thoughts.

Thanks.

Ron

I have the schematic here:

http://manuals.frigidaire.com/prodinfo_pdf/Anderson/A01511901.pdf

Schematic below (The URL above provides a better view of the schematic):

It's a nice freezer/fridge setup. The price is almost to good to pass up.

The fridge section on top of the clear shelves measure: 18 deep x 25 wide x 28-30 high.

The freezer section measures 14 deep x 23 wide x 14 high. High enough to store bottles upright!

For future reference:

https://www.homebrewtalk.com/f252/top-freezer-roper-fridge-fermentation-chamber-223499/

Last edited: