clonies720

Active Member

- Joined

- Apr 9, 2012

- Messages

- 33

- Reaction score

- 1

I made an Irish Red Ale from Midwest Supplies kit. Had a potentially minor issue while brewing though as I had to temporarily leave the brewing process in the hands of a friend, and the specialty grains reached a temperature way higher than the 155 F that Midwest recommends. But I believe that I adequately recovered from the mishap. My OG reading was consistent within Midwest's calculations, the color looked great, no funny smells or anything of the sort. I had another issue with my Shirron plate chiller. I got about 4.7 gallons into my primary before the plate chiller "Wort in" and "out" got clogged up with sediment. Had to flush it out with water and just gave up on the last .3 gallons or so. Should have topped my primary off with cold, clean water now that I think of it to make 5 gallons. *hangs head in shame* ETA: My original batch size was 5.5 gallons. Specialty grains were heated @ 155 F for 30 minutes, then steeped for another 10 off the heat. Add barley malt extract, stir in, bring to boil, add 1oz Cascade hops for 60 minutes @212 F, then add 1oz Fuggles hops for 2 minutes @ 212 F. Flamed out and got my 4.7ish gallons of wort chilled around 15 minutes. I was going to use a kickass pre-chiller with a stainless immersion wort chiller, but was missing a female thread adapter to fit on my plate chiller.

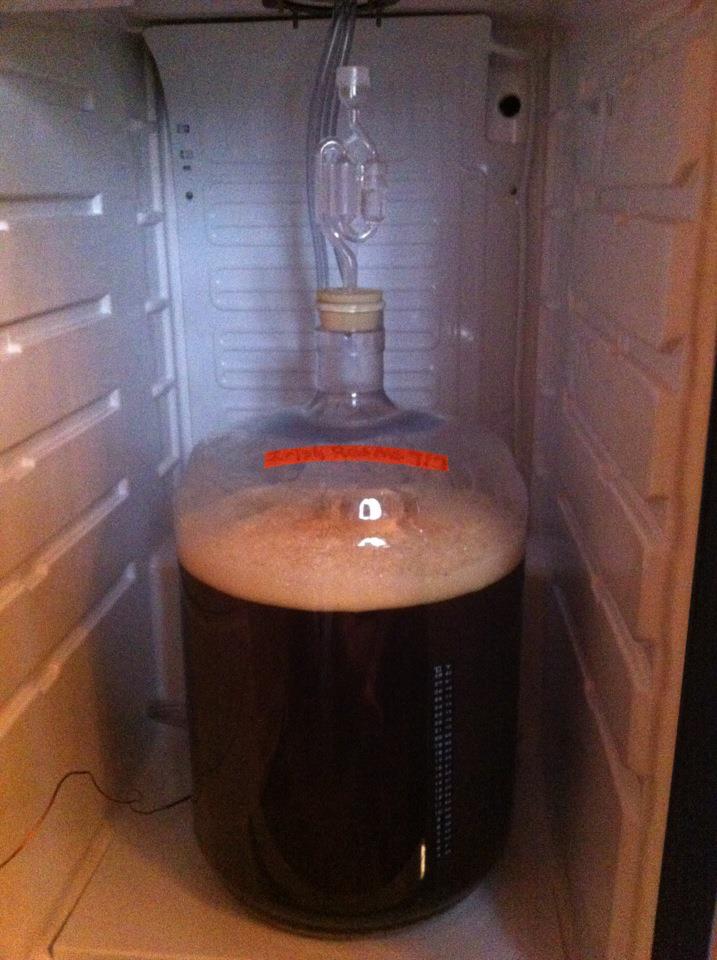

I sampled a bit of the wort after taking an OG and temperature reading, and it was actually pretty decent. Hah. Anyways, I pitched my Wyeast Activator and it's now cooling in my dual-tap kegerator (I'm shooting for around 68 degrees. Is this a good temp to ferment at?) until I get a fermentation chiller built in the meantime. But enough talk. Time for some pitchers. :rockin:

^20mm cartridge keg tap handle

Some of the equipment I used:

PolarWare 42 quart boiling pot w/ thermometer

Nylon hoses

6 gallon PET carboy

Shirron Economy Plate Chiller

Bayou Classic gas burner (they claim 135,000 BTU's but that sounds awfully high to me. It heated up my 5.5 gallon batch pretty quickly though)

Krausen is so pretty. However, I've been unable to figure out a blow-off setup for my primary 6 gallon PET fermenters and possibly for my 5 gallon glass carboys. Any suggestions?

Krausen is so pretty. However, I've been unable to figure out a blow-off setup for my primary 6 gallon PET fermenters and possibly for my 5 gallon glass carboys. Any suggestions?