I am currently trying to design a single tier brew stand that allows for 2 of the converted kegs to tip (MLT and Boil Kettle. I don't see a point for the HLT to tip), so that I can clean them easily. My father in law (lets call him Ed) can weld and has some scrap stainless etc, but I am willing to purchase things as needed.

My Keggles will have the tops completely taken off, as I will be able to tip them I wont need to lift them off the stand, and it will make it MUCH easier to clean, which is the goal.

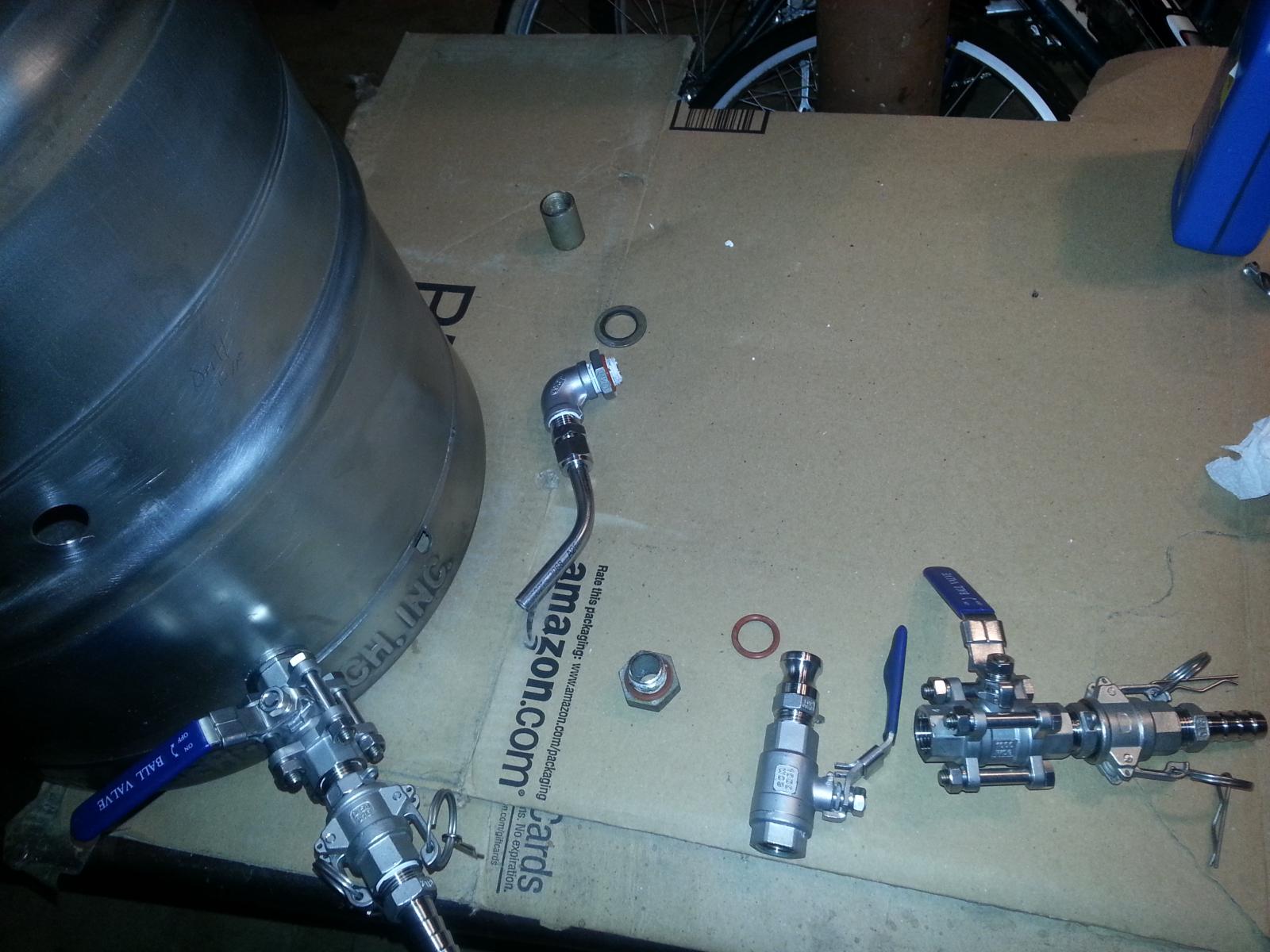

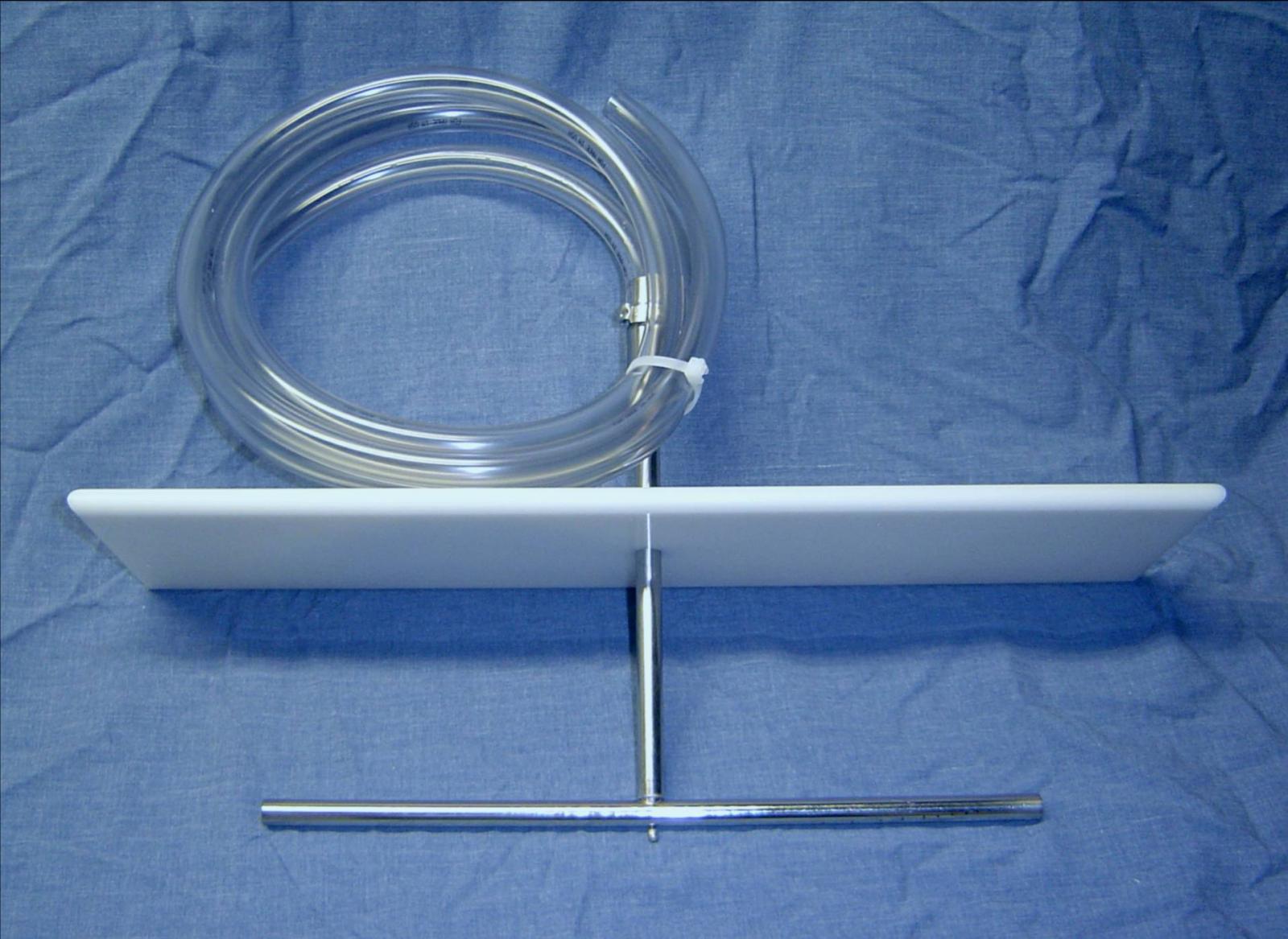

I plan to purchase 3 100,000 BTU burners under the keggles (3, obviously) and I have a chugger pump with hose and stainless fittings. I currently batch sparge and I plan to incorporate a recirculating mash with this set up and most likely, eventually, switch to fly sparging.

Ed thinks the best (or easiest) way to make them tippy is to weld a bar a little lower than halfway down the kegs (on each side) and to let them perch on a on a horizontal bar (with supports). Since they will be "floating" then the burners would need to be adjustable to swing or lower out of the way of the tipping keg.

I was thinking that just making a hinged bottom would be easier and give you better control to dump (as it will swing out and away from the stand) not to mention be more stable.

For those of you who have tippy stands (or even those who dont) can you lend some of your experience or knowledge here?

If anyone has any diagrams, build plans etc., they are always welcome to post so I can have something to start with and improve if necessary, or simply copy if it seems to be a "perfect" build.

My Keggles will have the tops completely taken off, as I will be able to tip them I wont need to lift them off the stand, and it will make it MUCH easier to clean, which is the goal.

I plan to purchase 3 100,000 BTU burners under the keggles (3, obviously) and I have a chugger pump with hose and stainless fittings. I currently batch sparge and I plan to incorporate a recirculating mash with this set up and most likely, eventually, switch to fly sparging.

Ed thinks the best (or easiest) way to make them tippy is to weld a bar a little lower than halfway down the kegs (on each side) and to let them perch on a on a horizontal bar (with supports). Since they will be "floating" then the burners would need to be adjustable to swing or lower out of the way of the tipping keg.

I was thinking that just making a hinged bottom would be easier and give you better control to dump (as it will swing out and away from the stand) not to mention be more stable.

For those of you who have tippy stands (or even those who dont) can you lend some of your experience or knowledge here?

If anyone has any diagrams, build plans etc., they are always welcome to post so I can have something to start with and improve if necessary, or simply copy if it seems to be a "perfect" build.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)