Hello all!

I have finally been able to get into brewing (been waiting to for a while but haven't had the time) and I have now completed two of my own simple Blonde Ale recipes. However, things started out rough in my first batch but ended up better in the second. The problem is that both batches have had a very low OG of 1.030 instead of the target 1.047. Exact same OG for both batches even after adjusting my BeerSmith profiles for the second batch. I've searched the web and looked at a bunch of forums here and couldn't figure out a definitive answer. So, here are the details and I hope you can help pinpoint where I'm going wrong. I'm sorry for the long post, but every thread I read was very short and it seemed solutions were hard to make with little info, so hopefully this will make it more painless.

The BeerSmith recipe is also attached if you would like to see where things are at (Name is Cat & Carrot in BeerSmith).

Brewing equipment:

-8 gallon Alfred brewing pot

-11.7 gallon Mash King mash tun with a 12'' bazooka tube (I have a false bottom but there would be way too much dead space if I'm brewing small batches)

-Secura 8100MC 1800W induction cooktop (used this in a brewing class and it did the trick, and I'm only brewing small batches for now. I would grab a propane burner for larger batches.)

-Grains are milled at the store when they are purchased.

-Brewers Best pH strips (I don't trust these. pH meter is the next purchase)

-Hydrometer calibrated for 68F

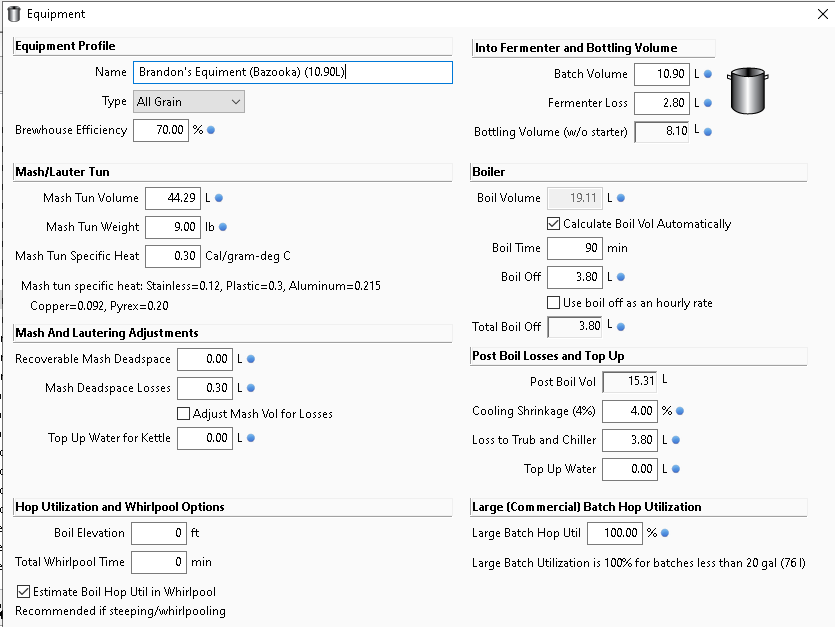

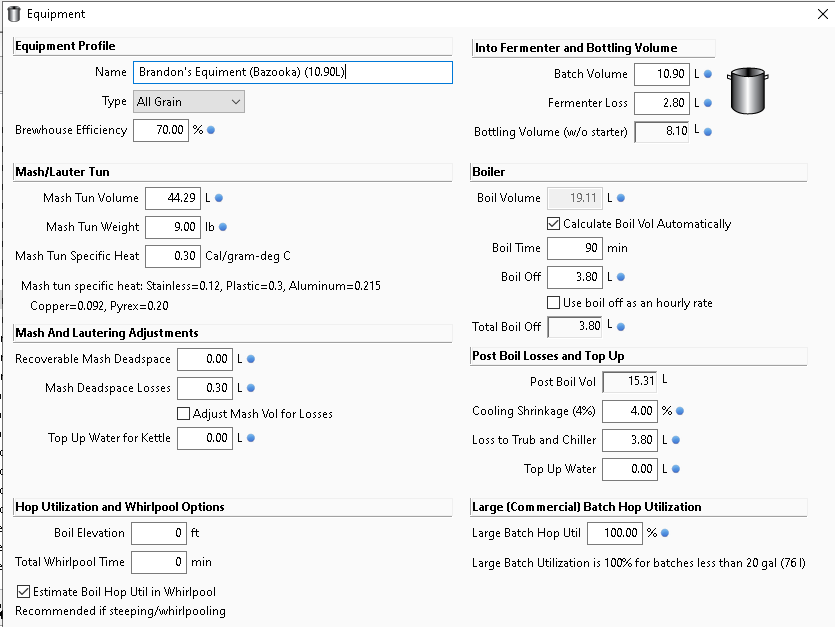

Attached below are my current BeerSmith equipment profile settings (adjusted after the two batches, sorry I can't accurately recall what they were before but I can ballpark it if need be):

I create my recipes as if they were 5gal batches and simply scale them down.

Recipes were followed by the Brew Steps tab.

Attempt 1:

Recipe:

-3.3lbs Bohemian pilsner

-1.11lbs pale Canadian 2 row

-0.75lbs honey malt

Process (All volumes/temps given/estimated by BeerSmith):

-Hit strike temp, added 6.11L of water and threw the grains slowly in and stirred well. This dropped the mash temp lower than I was expecting to 136.4F, so I added another 1L of water at 194F but this only raised the temp to 140F. So already I was mashing with way too low of a temperature. After 10 minutes I checked the pH, pH was estimated to be 5.72 with my water profile (so I would add lactic acid) but my pH strips were measuring at about 5 (how is this possible?). I tried adding baking soda to raise it (about a teaspoon) and my strip read 6.4. So I added acid and it went right back down to 5 on the strip. It was a mess, so I gave up and just let the mash go.

-Mashed for 75mins, mashed out for 10mins with 2.9L of 194F water.

-Fly sparged with 16.7L of 170F water. I sparged way too quickly, let the grain bed dry out a few times.

-Pre-boil gravity was 1.028 (I mixed the wort in the kettle to get an accurate reading and took the measurement at 68F).

-Estimated pre-boil was 24.08L. Boiled for 60 minutes (started the timer when I had a low rolling boil). Boiled off about a gallon, ended with 20.2L (estimated 17.27L) after chilling. Lost 1 gallon to trub.

-Measured OG at 68F and had a reading of 1.030 (target 1.047).

For this attempt, I had a mash efficiency of 106% in BeerSmith, so obviously something was wrong in my profiles. Mash efficiency was set to 70%.

Attempt 2 (learned from my mistakes):

Recipe:

-3.5lbs German Pilsner

-1.15 Canadian 2 row

-0.6lbs honey malt

Process (All volumes/temps given/estimated by BeerSmith):

-Hit strike temp, added 6.15L of water, poured grain in slowly and stirred well. Mash temp was on target at 147.2F. After 10 minutes I checked the pH (estimated 5.74) and the strips read 5. There is no way it would drop this low, hence why I don't trust the strips. Based on this reading, I didn't bother adding anything this time and just left it. I let the mash go for 75 minutes. Mashed out for 10 minutes with 4L of 205F water.

-Fly sparged with 16.5L of 170F water. Sparging went really well, kept about 2.5cm above the grain bed the whole time, used a plastic strainer to disperse water and avoid tunneling, sparged with a good rate of water in = water out. (took about 40 minutes)

-Pre-boil gravity was 1.030 at 68F.

-Pre-boil volume was 23.94L. Boiled for 90mins, boiled off 1 gallon. Ended with 20.1L after chilling when it was supposed to be 15.51L. After seeing this I changed the boil-off to 1 gallon in BeerSmith.

-Measured OG at 68F and had a reading of 1.030 (target 1.047).

Luckily this time I had some DME in case this happened, so I managed to save this batch but I definitely don't want to have to do this every time. .

Efficiency was still set at 70%, mash efficiency was at 95.7% so something is still off because there is no way I'm even able to come close to that with my set up.

I can only think of two possibilities that might be contributing to the low OG:

On the bright side, the first batch is now done fermenting and other than the weak alcohol content, the flavour, colour and clarity have all come out perfectly so far!

Cheers,

Brandon

I have finally been able to get into brewing (been waiting to for a while but haven't had the time) and I have now completed two of my own simple Blonde Ale recipes. However, things started out rough in my first batch but ended up better in the second. The problem is that both batches have had a very low OG of 1.030 instead of the target 1.047. Exact same OG for both batches even after adjusting my BeerSmith profiles for the second batch. I've searched the web and looked at a bunch of forums here and couldn't figure out a definitive answer. So, here are the details and I hope you can help pinpoint where I'm going wrong. I'm sorry for the long post, but every thread I read was very short and it seemed solutions were hard to make with little info, so hopefully this will make it more painless.

The BeerSmith recipe is also attached if you would like to see where things are at (Name is Cat & Carrot in BeerSmith).

Brewing equipment:

-8 gallon Alfred brewing pot

-11.7 gallon Mash King mash tun with a 12'' bazooka tube (I have a false bottom but there would be way too much dead space if I'm brewing small batches)

-Secura 8100MC 1800W induction cooktop (used this in a brewing class and it did the trick, and I'm only brewing small batches for now. I would grab a propane burner for larger batches.)

-Grains are milled at the store when they are purchased.

-Brewers Best pH strips (I don't trust these. pH meter is the next purchase)

-Hydrometer calibrated for 68F

Attached below are my current BeerSmith equipment profile settings (adjusted after the two batches, sorry I can't accurately recall what they were before but I can ballpark it if need be):

I create my recipes as if they were 5gal batches and simply scale them down.

Recipes were followed by the Brew Steps tab.

Attempt 1:

Recipe:

-3.3lbs Bohemian pilsner

-1.11lbs pale Canadian 2 row

-0.75lbs honey malt

Process (All volumes/temps given/estimated by BeerSmith):

-Hit strike temp, added 6.11L of water and threw the grains slowly in and stirred well. This dropped the mash temp lower than I was expecting to 136.4F, so I added another 1L of water at 194F but this only raised the temp to 140F. So already I was mashing with way too low of a temperature. After 10 minutes I checked the pH, pH was estimated to be 5.72 with my water profile (so I would add lactic acid) but my pH strips were measuring at about 5 (how is this possible?). I tried adding baking soda to raise it (about a teaspoon) and my strip read 6.4. So I added acid and it went right back down to 5 on the strip. It was a mess, so I gave up and just let the mash go.

-Mashed for 75mins, mashed out for 10mins with 2.9L of 194F water.

-Fly sparged with 16.7L of 170F water. I sparged way too quickly, let the grain bed dry out a few times.

-Pre-boil gravity was 1.028 (I mixed the wort in the kettle to get an accurate reading and took the measurement at 68F).

-Estimated pre-boil was 24.08L. Boiled for 60 minutes (started the timer when I had a low rolling boil). Boiled off about a gallon, ended with 20.2L (estimated 17.27L) after chilling. Lost 1 gallon to trub.

-Measured OG at 68F and had a reading of 1.030 (target 1.047).

For this attempt, I had a mash efficiency of 106% in BeerSmith, so obviously something was wrong in my profiles. Mash efficiency was set to 70%.

Attempt 2 (learned from my mistakes):

Recipe:

-3.5lbs German Pilsner

-1.15 Canadian 2 row

-0.6lbs honey malt

Process (All volumes/temps given/estimated by BeerSmith):

-Hit strike temp, added 6.15L of water, poured grain in slowly and stirred well. Mash temp was on target at 147.2F. After 10 minutes I checked the pH (estimated 5.74) and the strips read 5. There is no way it would drop this low, hence why I don't trust the strips. Based on this reading, I didn't bother adding anything this time and just left it. I let the mash go for 75 minutes. Mashed out for 10 minutes with 4L of 205F water.

-Fly sparged with 16.5L of 170F water. Sparging went really well, kept about 2.5cm above the grain bed the whole time, used a plastic strainer to disperse water and avoid tunneling, sparged with a good rate of water in = water out. (took about 40 minutes)

-Pre-boil gravity was 1.030 at 68F.

-Pre-boil volume was 23.94L. Boiled for 90mins, boiled off 1 gallon. Ended with 20.1L after chilling when it was supposed to be 15.51L. After seeing this I changed the boil-off to 1 gallon in BeerSmith.

-Measured OG at 68F and had a reading of 1.030 (target 1.047).

Luckily this time I had some DME in case this happened, so I managed to save this batch but I definitely don't want to have to do this every time. .

Efficiency was still set at 70%, mash efficiency was at 95.7% so something is still off because there is no way I'm even able to come close to that with my set up.

I can only think of two possibilities that might be contributing to the low OG:

- The pH in the mash was actually too low. However, I have no idea how this is possible or how I would be able to change that other than doing custom water chemistry (I would rather not for the time being until things start to go well). Beersmith has a predicted pH of 5.7 with my water profile and grain bill (obviously did not get that if the strips are accurate). Again, this was with zero additions to try to change the pH. Before brewing, I take my total water + extra and bring it to a boil to get rid of any chlorine that may be in it.

- I had my boil off set to 2 gallons when I actually only boiled off 1 gallon. I changed this after the fact and my recipe was altered by a few liters less so I doubt this would have a terribly large impact. Or would that small difference actually dilute the wort that much? In my second batch I had an extra 5L of wort so did that throw it off?

On the bright side, the first batch is now done fermenting and other than the weak alcohol content, the flavour, colour and clarity have all come out perfectly so far!

Cheers,

Brandon

Attachments

Last edited: