I was on a mission today. With company coming Thursday evening I needed to get some serious work done. I started at 9 AM Wed. and (minus a dinner break and one trip to Home Depot) have worked straight through until 6 AM.

I started this morning by moving all my fermenting beers into kegs and getting them hooked up to CO2. The peanut butter stout had a huge oil slick on top, I believe I was able to leave most, if not all, of it behind when I transferred. It had a huge peanut butter aroma, can't wait to try this.

I got everything measured and figured out exactly where I wanted my drip tray so I could cut and lay my tile.

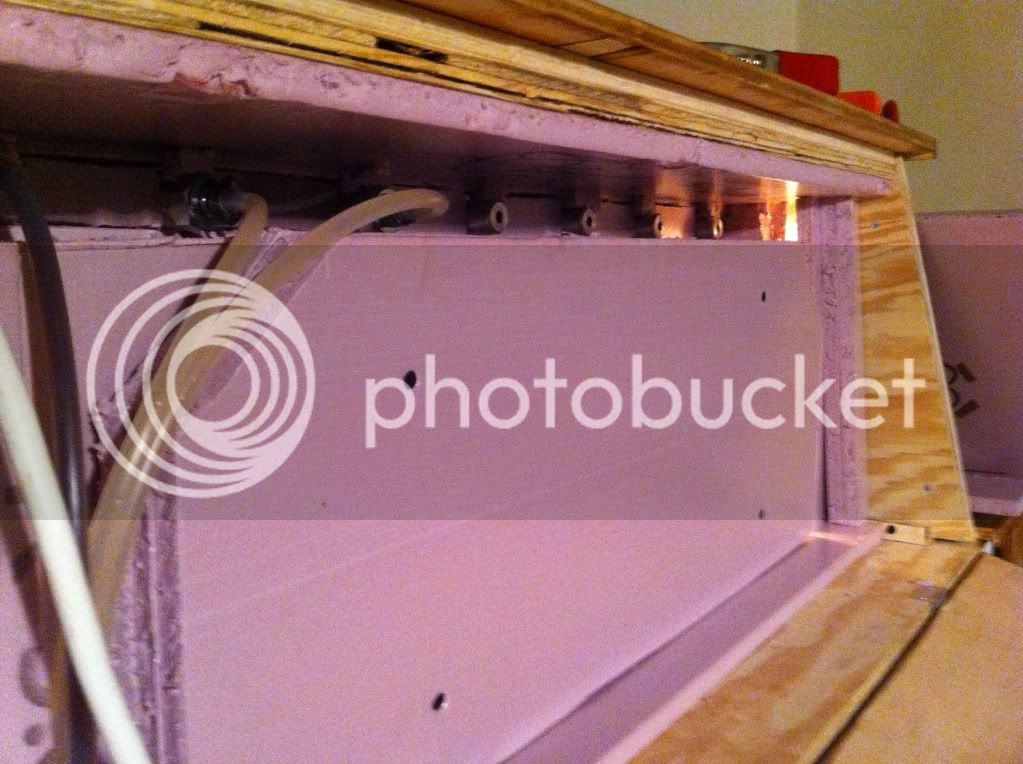

Then a mini disaster hit. I was lifting the lid in order to screw in the back pieces of the skirt and I forgot that the coffin was not attached yet. It went off the back end and the top piece was ripped out. I had to disassemble the whole thing and replace the top pieces then put it back together. Luckily the two perlicks that were attached seemed to be fine and the tile survived. After a few choice words and two hours I got it fixed.

After that I got trim pieces cut and put on all of my borders. I also stuck some wood putty in my joints to cover up my woodworking shortcomings.

I was very happy with how the tile come together, my drip tray fits perfectly.

After that it was a few hours of grouting, staining and assembling the hardware.

I still need to put a coat of varnish on, sink the drip tray so it is level with the tile, seal the grout and install the base skirt, but at least it's presentable to the public now.