sandyeggoxj

Well-Known Member

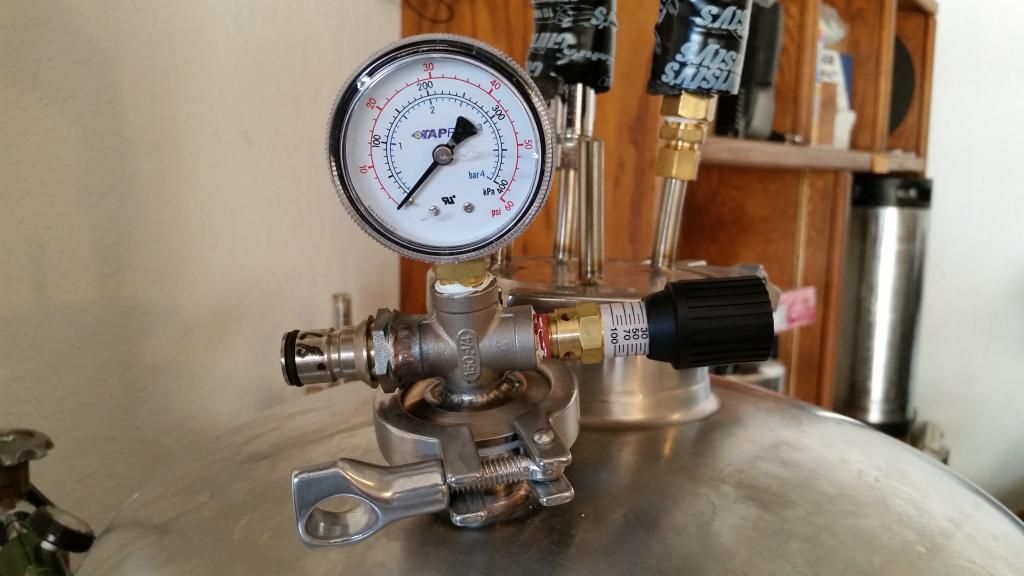

I am going to make one of these: http://brewhemoth.com/spunding-valve

I just got a fancy new pulsed tig welder in the mail from some cyber monday shopping so now I am looking for projects. Does anybody have an idea on how to keep the poppet in place? Everything else is pretty straight forward. I should be able to build it for about $30 plus some time. So that is a considerable savings!

I still need to figure out how to keep the poppet in place. It might just hold itself there with the 1/4" pipe fitting. I am looking for bright ideas.

I just got a fancy new pulsed tig welder in the mail from some cyber monday shopping so now I am looking for projects. Does anybody have an idea on how to keep the poppet in place? Everything else is pretty straight forward. I should be able to build it for about $30 plus some time. So that is a considerable savings!

I still need to figure out how to keep the poppet in place. It might just hold itself there with the 1/4" pipe fitting. I am looking for bright ideas.