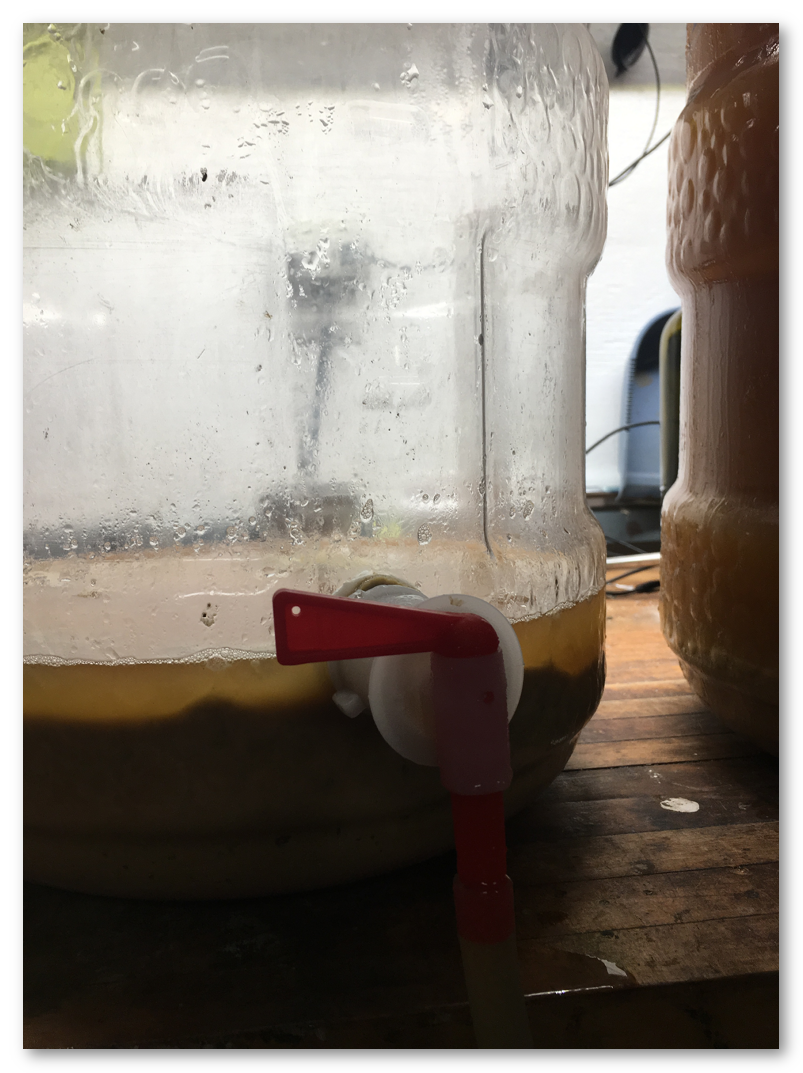

I am finally getting around to adding spigots to my carboys. Just can't stand to use the autosiphon one more time. Couple of questions:

I think I want it a little higher than the highest expected trub/hop crap. Then I can just tip it a little forward if the trub is well under the spigot. Thoughts?

BTW, I bought the spigots below on Amazon and I'm mounting then into plastic Big Mouth Bubblers. Hope the dumb bubble pattern doesn't affect the seal.

I bought these: https://www.amazon.com/gp/product/B07G8WD4LY/ref=ppx_yo_dt_b_asin_title_o03_s00?ie=UTF8&psc=1

- What height, from the bottom of the carboy to the center of the hole, do you guys have your's at?

- How did you drill your hole (if you did it yourself)? I've got step bits and hole saws here, I figure one is better than the other.

I think I want it a little higher than the highest expected trub/hop crap. Then I can just tip it a little forward if the trub is well under the spigot. Thoughts?

BTW, I bought the spigots below on Amazon and I'm mounting then into plastic Big Mouth Bubblers. Hope the dumb bubble pattern doesn't affect the seal.

I bought these: https://www.amazon.com/gp/product/B07G8WD4LY/ref=ppx_yo_dt_b_asin_title_o03_s00?ie=UTF8&psc=1

Last edited: