Dear Homebrewing friends I continue in this thread in order to highlight main SmartPID features and functions and collect your feedback during the project

Before entering technical details few words about the philosophy and idea behind the project

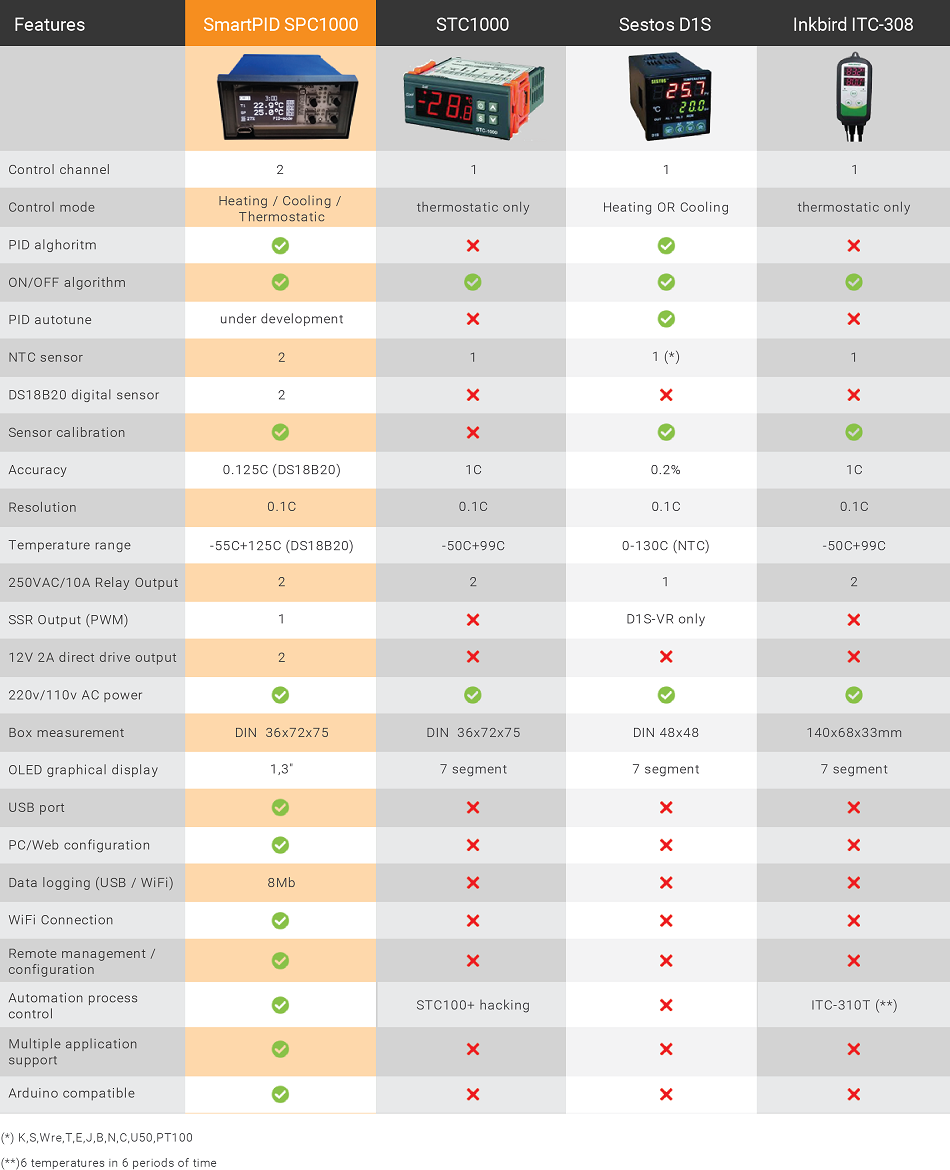

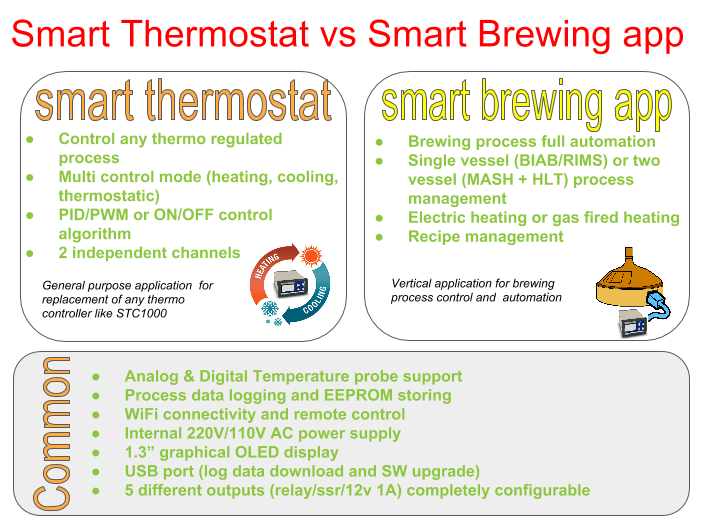

When I start designing the SmatPID I try to capture some requirements and functionalities that are actually not present in low cost thermostat like STC1000 and are more typical in the professional control device (PLC) but at the same time I put lot of effort to keep it simple, accessible, affordable for a consumer market and DIY enthusiast

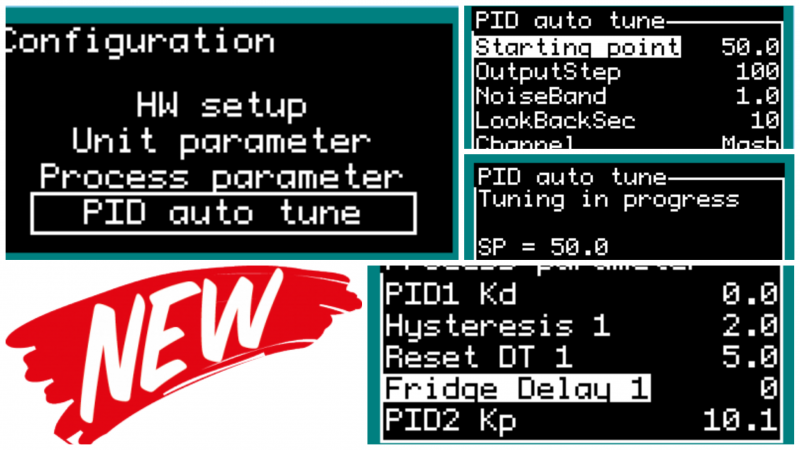

apart form the core temperature control features (PID/PWM etc..) indeed very advanced and powerful t the main innovation I have introduced that make SmartPID unique are

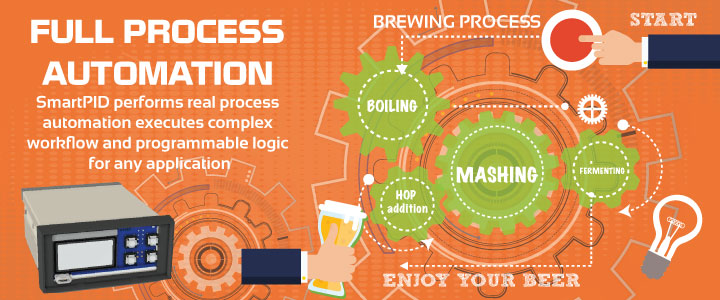

Full process automation

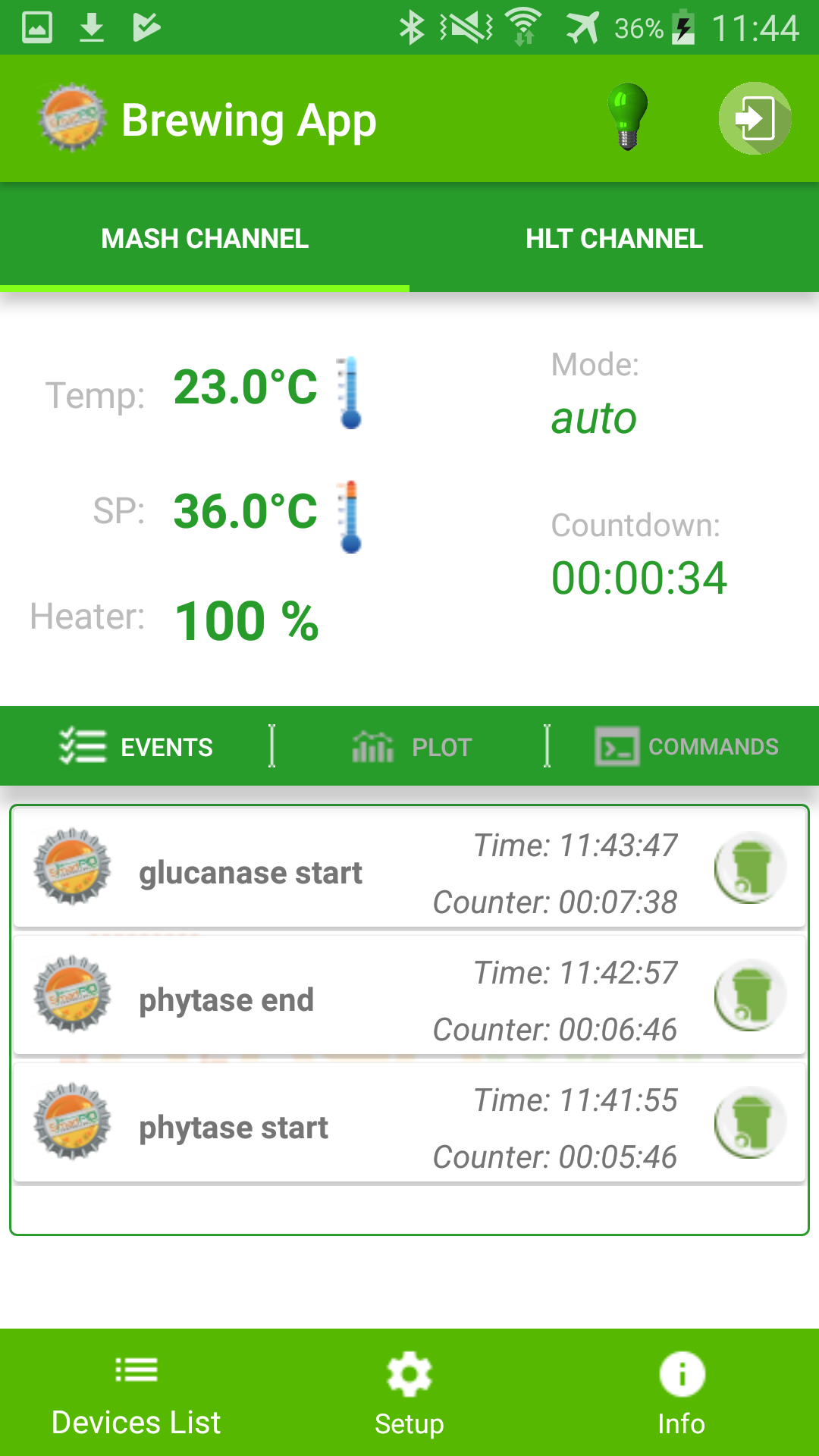

Thanks to the power of the platform it's possible to develop custom application that needs process control with complex service logic and manage a complete workflow.

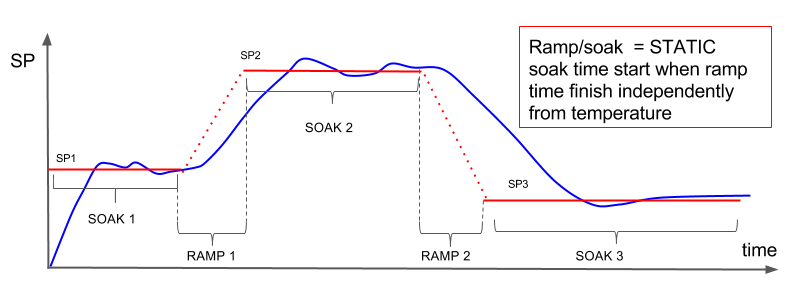

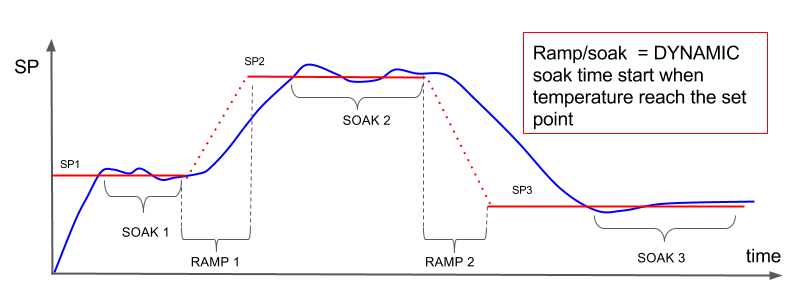

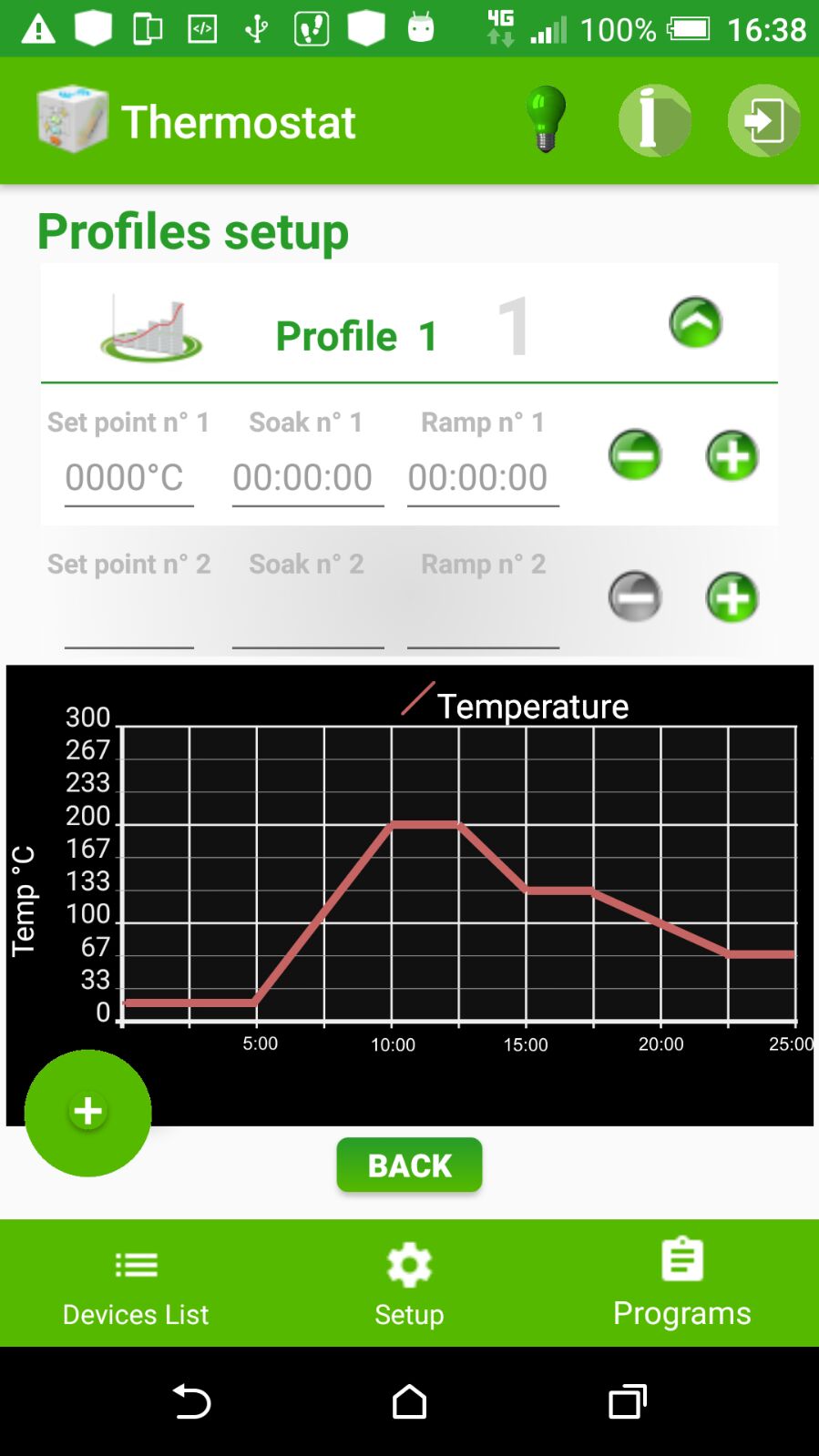

Basic thermostat just simply ready temperature and control a relay according to set point..In smartPID you can program steps, ramps, triggers, alarms and manage complex temperature profile over the time.

Typical example is food processing like beer brewing, cheese making or food drying where according to specific recipe parameters the heating process should be managed step by step controlling and orchestrating different elements (heater, pump, fan..)

Data logging and export (USB & wifi)

The possibility to log all process data and analyse real time or off line is another typical feature that is available only on professional devices or with external data logger.

SmartPID has an internal 8Mbit EEPROM where all the process data (temperature, set point, PWM power, control direction etc,,) are logged and can be accessed either locally via USB and a desktop application (CSV export) or remotely pushed via wifi connection to a cloud server.

WiFi connectivity for remote management and IoT cloud integration

Wifi connectivity and cloud integration is what make SmartPID really smart !

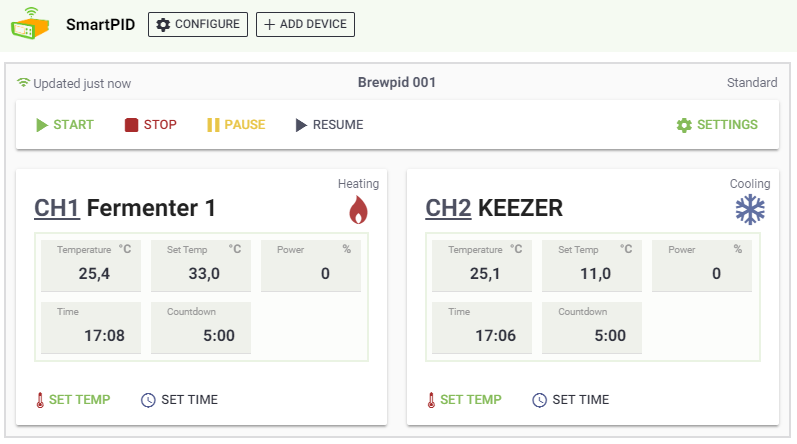

Small wifi optional module is integrated in the SmarPID box and once connected to the wifi access the device can provide lot of new feature

remote management → configuration and control of setup parameter and process parameter from any location via web or smartphone

data logg→ real time monitoring of main process parameter and storage in the cloud server

for the development and design phase the thingspeak cloud service has been used , a private cloud server will be deployed after project founding

DIN Box

Another key driver for the design was the box size and we decide to use a standard DIN box in order to make SmartpID ultra compact and backward compatible with STC1000 like thermostat, you can just unplug your current controller and plug SmartPID to get the new full set of features

Engineering all the HW to support the new features has been very challenging but the result is a very powerful platform with powerful CPU, lot of memory and I/O capabilities that is the base line for developing powerful applications

Arduino Compatibility

Last but not least important driver was to keep as much as possible the platform open and easy programmable so the natural choice was to do development under Arduino umbrella. The component selection like the MCU (SAMD21 arduino Zero and MKR1000 IoT new board) and the architure are fully arduino compatible. I have developed a custom bootloader and specific board definition that can be imported in the Arduino IDE so you can just connect SmartPID via USB port to your PC and develop you sketch using the arduino tool-chain and all the supported libraries.

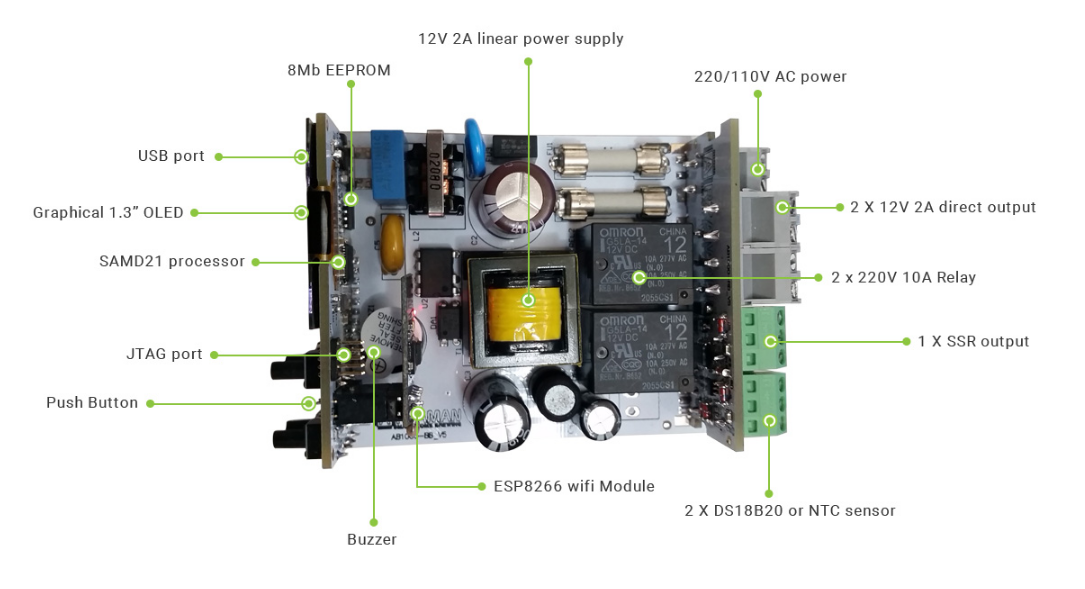

Lets now have an overview to HW and core features

HW configuration

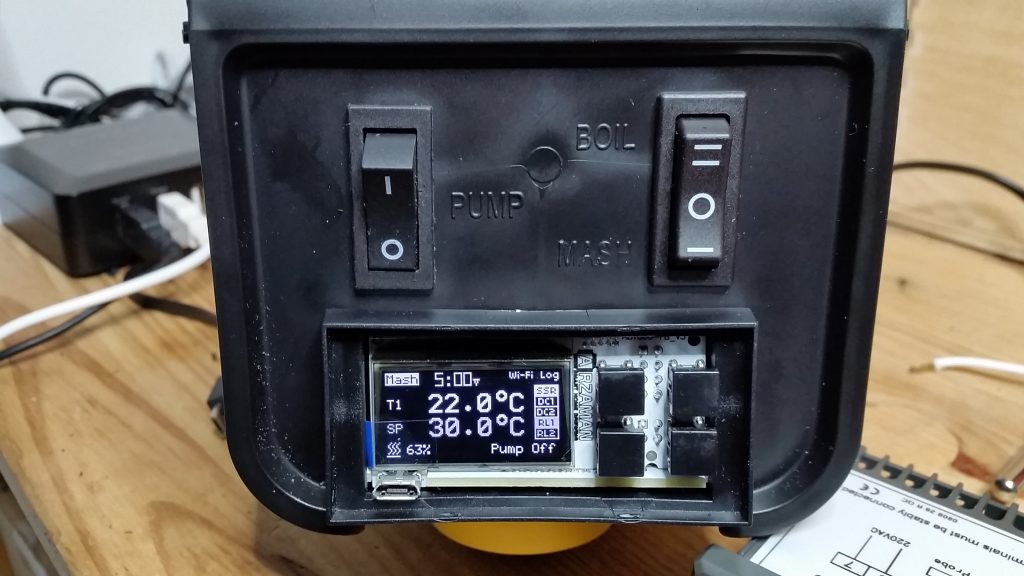

-SAMD21 processor ARM cortex M0+

-8Mbit EEPROM for data log, recipe storage etc..

-1.3 OLED graphical display

-USB front port for programming, SW upgrade, data logging

-4 tactile switch to navigate trough menu

-1x Buzzer

-Jtag/SWD port

-WIFI module (detachable)

-110/220 V AC power supply

-2x temp probe input (DS18B20 or NTC)

-2x 220v AC 10A Relay output

-1x SSR output

-2x 12V 1A direct drive output

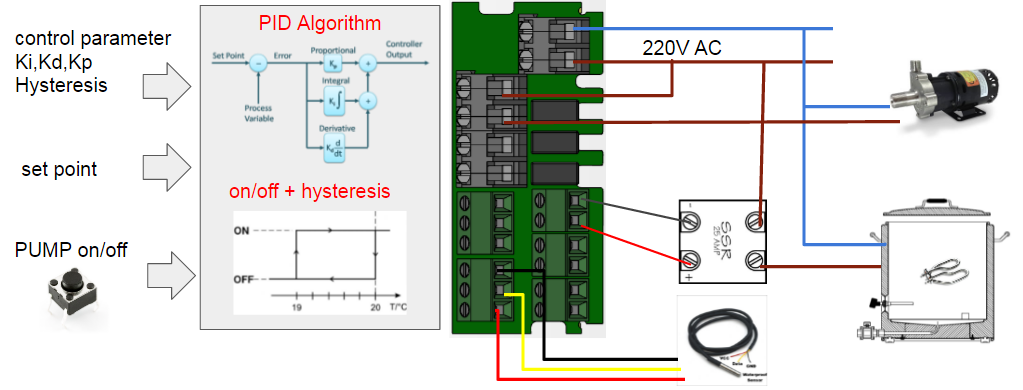

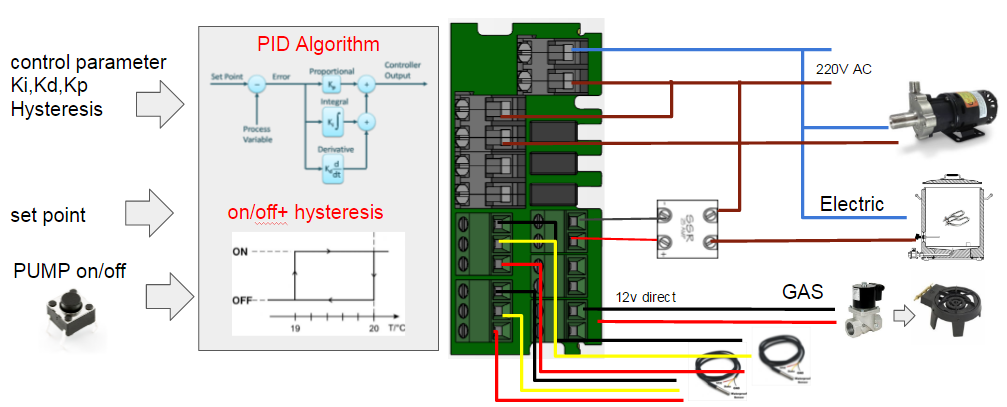

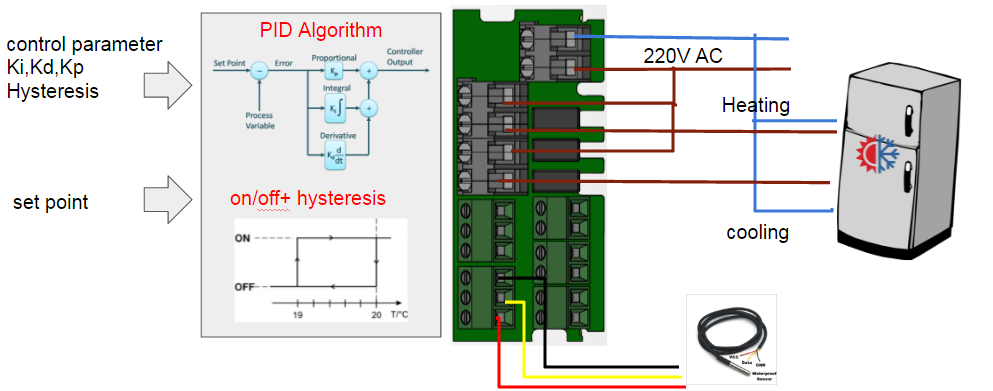

The core control functions are

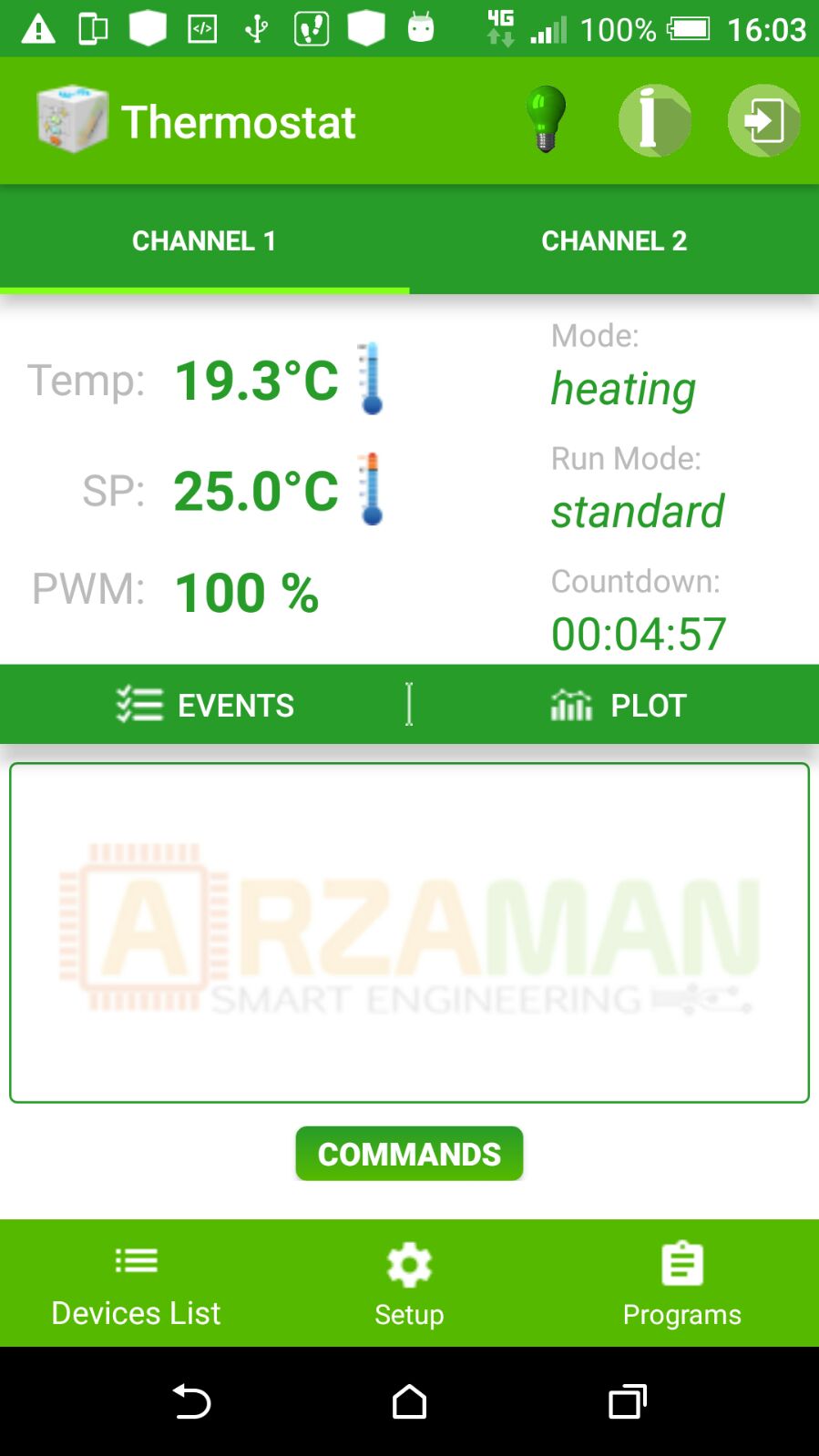

-DUAL Independent control channel

-Multi control mode (heating , cooling or thermostatic)

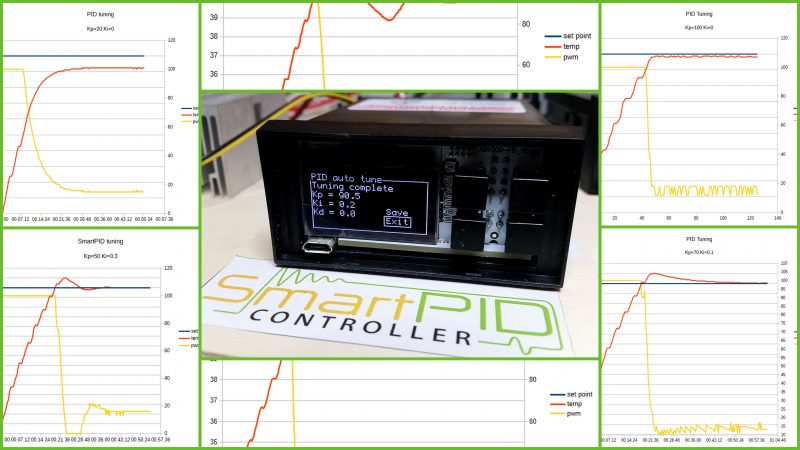

-Dual control algorithm (PID or ON/OFF)

Is this little box powerful, flexible, smart enough for your applications ?

Next posts try to go in detail of major functions and remote management part

Any feedback is appreciated !

Arzaman

http://smartpid.com

https://www.facebook.com/smartPID