gsanstra

Well-Known Member

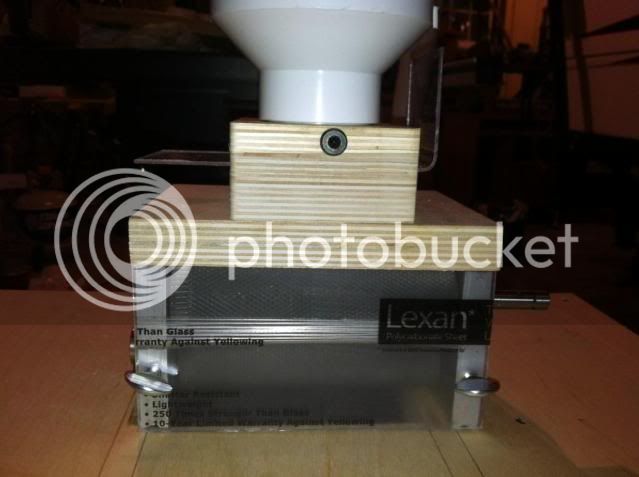

So I just got my new 3D in the mail today (finally), and I'm considering a compact design for the hopper. I like both of these designs:

http://www.slobrewer.com/howto/building-a-compact-crankandstein-mill-base-and-hopper/

http://maltmunchingmashmonsters.com/diy/crankandstein.html

I'm wondering what other variations you all have made for the enclosure / hopper. So show me your designs!

Thinking about going with the second design but with bend aluminum sides to increase the hooper capacity.

Thoughts?

http://www.slobrewer.com/howto/building-a-compact-crankandstein-mill-base-and-hopper/

http://maltmunchingmashmonsters.com/diy/crankandstein.html

I'm wondering what other variations you all have made for the enclosure / hopper. So show me your designs!

Thinking about going with the second design but with bend aluminum sides to increase the hooper capacity.

Thoughts?