user 40839

Well-Known Member

- Joined

- Jul 13, 2009

- Messages

- 1,176

- Reaction score

- 86

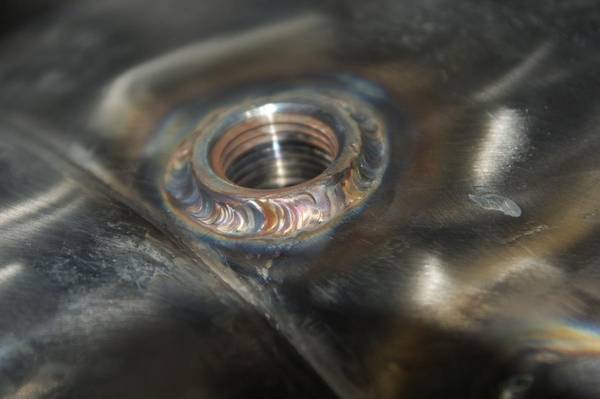

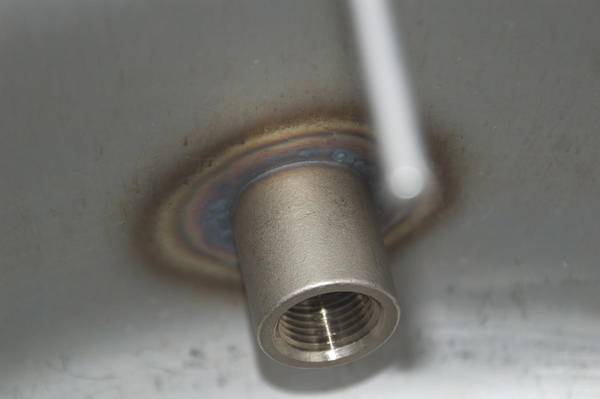

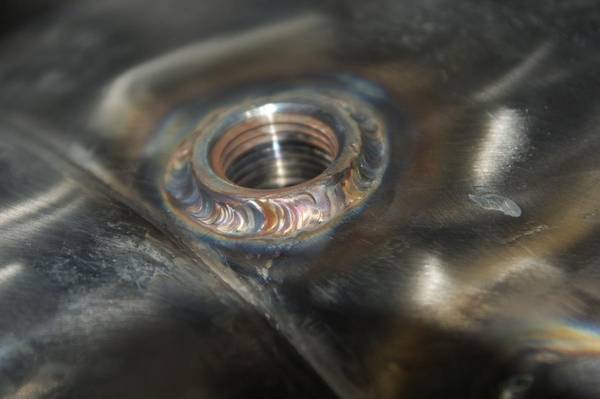

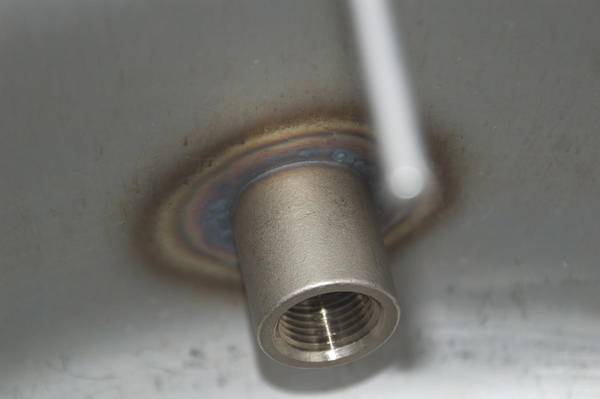

Okay, got sick of my weldless fittings leaking, and having to chip stalagmites of burned wort off my keggles and brewstand at the end of every session, so I searched for a place to get them welded. After visiting the local shops and getting prices like $75 per weld (hahahah!) I resorted to Craigslist and searched for a TIG welder. Found a guy willing to do them for $20 a pop, sanitary welds. (At least when I told him what I wanted, he automatically knew that they'd need to be back gassed to avoid sugaring.) Here's the result:

Am I being hyper critical here, or do these welds look a bit crap? The bottom one is EASILY the best of the five welds I had done, but the other ones just look... meh. He did say if I wasn't happy with them that he'd make it right, but...

Am I being hyper critical here, or do these welds look a bit crap? The bottom one is EASILY the best of the five welds I had done, but the other ones just look... meh. He did say if I wasn't happy with them that he'd make it right, but...