You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rims or HERMS

- Thread starter SbNepTX

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

SoCal-Doug

Well-Known Member

Sabco makes a good machine. A bit outdated and a little pricey relative to other comparable systems. I've used them in the past and designed my last couple systems around some of their concepts. I found the whole computer thing to be overkill and a bit hokey. It's a lot of money and complexity for a screen to tell me to turn the burner on because the RIMS can't keep up. I do prefer their sparge method over anything else and the simple 2-level layout and plumbing is great.

I can't speak to Blichmann, but they appear solid and should get the job done well. I haven't heard any real negative about them yet, other than price.

I've had both RIMS and HERMS systems and keep going back to HERMS. I honestly don't think either is much "better" than the other. Both are a similar workload with slightly different brew day numbers. I've never had or witnessed scorching on a RIMS but some people have. Many complain about smaller RIMS elements being slow to ramp up (hence sabco adding burners). I agree. A fatty 5500W element really makes things happen.

Either method on a good system should get you mash efficiencies in the 90's and very repeatable brews. Having gone to electric, i'll never go back. There's just too much pro and very little con. I put propane on mine as an available option, but have yet to use it.

I did a "hybrid" with what I liked about Sabco and made it a HERMS. I liked the frame dimensions, plumbing and layout. If you shop smartly and are kinda handy with fabricating and wiring, you can do a nice rig for easily 1/3 the price of a commercial system. If someone else does some labor for you, it will go up, but not to a $7000 sabco level. I might be into this ghetto rig for $2K.

Just some thoughts

I can't speak to Blichmann, but they appear solid and should get the job done well. I haven't heard any real negative about them yet, other than price.

I've had both RIMS and HERMS systems and keep going back to HERMS. I honestly don't think either is much "better" than the other. Both are a similar workload with slightly different brew day numbers. I've never had or witnessed scorching on a RIMS but some people have. Many complain about smaller RIMS elements being slow to ramp up (hence sabco adding burners). I agree. A fatty 5500W element really makes things happen.

Either method on a good system should get you mash efficiencies in the 90's and very repeatable brews. Having gone to electric, i'll never go back. There's just too much pro and very little con. I put propane on mine as an available option, but have yet to use it.

I did a "hybrid" with what I liked about Sabco and made it a HERMS. I liked the frame dimensions, plumbing and layout. If you shop smartly and are kinda handy with fabricating and wiring, you can do a nice rig for easily 1/3 the price of a commercial system. If someone else does some labor for you, it will go up, but not to a $7000 sabco level. I might be into this ghetto rig for $2K.

Just some thoughts

augiedoggy

Well-Known Member

I started with herms and once I got my rims configured properly I can honestly say I'll never go back to herms. if built correctly RIMS has too many advantages to ignore... there are plenty of threads on here debating this old subject though.

Of course everyone's experiences and equipment is different as well as their environment and implementation of the equipment. I believe out of the box "Brew Machines" do often have compromises. This forum if full of threads about them and comparing them.

I started with analog pids and switches and went to an arduino based electric system which I actually found had a lot of advantages and capabilities (for both fermentation control and brewing)... They both make the same quality beer though..

Of course everyone's experiences and equipment is different as well as their environment and implementation of the equipment. I believe out of the box "Brew Machines" do often have compromises. This forum if full of threads about them and comparing them.

I started with analog pids and switches and went to an arduino based electric system which I actually found had a lot of advantages and capabilities (for both fermentation control and brewing)... They both make the same quality beer though..

I 100% agree with @augiedoggy... this has been frequently debated a here, with users of one or the other declaring theirs is best. I am no different as I don't have experience with HERMS. But conceptually, I struggle with the idea of needing to heat liquid in order to heat more liquid. Why not just heat the liquid?

The bigger issue many have is the need for an HLT and RIMS - this would mean 3 elements (along with BK) so more electronics, hardware, etc. In my system, I have eliminated the HLT by doing on-demand fly sparging, but 2 vessel can also be implemented by doing no sparging, batch sparging, drain before sparging, cold sparging, or all water in sparging. At the end of the day we are heating and rinsing porous grains and there are lots of ways to skin that cat.

The bigger issue many have is the need for an HLT and RIMS - this would mean 3 elements (along with BK) so more electronics, hardware, etc. In my system, I have eliminated the HLT by doing on-demand fly sparging, but 2 vessel can also be implemented by doing no sparging, batch sparging, drain before sparging, cold sparging, or all water in sparging. At the end of the day we are heating and rinsing porous grains and there are lots of ways to skin that cat.

shoo

Well-Known Member

- Joined

- Aug 14, 2017

- Messages

- 93

- Reaction score

- 28

At the end of the day we are heating and rinsing porous grains and there are lots of ways to skin that cat.

Great reminder.

I just "finished" (read: is now functional, but still more to do) building a weird RIMS/HERMS hybrid. As with all home built systems, mine has a few weird requirements and features, mine being that everything needs to be portable, cheap, use what I already had for vessels, can't require anything more than a regular old 20A 120V outlet + an electric stove top to power, and relatively easy to clean.

What I ended up with is a 2.5 vessel system. My MT is a cooler system with ball valve at the bottom, but with a movable depth temperature probe, float switch, and sparge arm built into the lit. My HLT doubles as my BK, and has a built in ball valve and whirlpool arm, but no element built in. Heating the HLT is taken care of via my RIMS tube. Wort runs through a standard immersion chiller copper heat exchange coil which is placed in the HLT. RIMS tube circulates water in the HLT. So I have HERMS powered by RIMS. The HLT is on the stovetop if I want to manually accelerate heating the sparge water.

The reasoning for this is that no wort ever touches a heating element, nor does it ever enter the RIMS tube. That means I will rarely, if ever, have to clean the RIMS element or tube, since it's only ever touching water. Similarly, I have one chugger which does the bulk of the work and can handle the wort, but only a little brown $20 12v is needed for the RIMS water. Bonus: no chance of scorching if I screw up. Plus I get the benefits of HERMS (heating my sparge water and mash to sparging temps simultaneously). Extra bonus: if this system turns out to suck, I haven't bought or made anything that can't be used some other way, so no waste.

First attempted brew with the full system scheduled for Sunday. Wish me luck!

Edit: $1,350 for the SABCO RIMS system seems crazy expensive to me. You can definitely buy a pre-built RIMS system for much cheaper, such as this one from BrewHardware. For what it's worth, all of the purchases I made for the above system came in at a fraction of the cost of that SABCO RIMS system, and probably roughly similar to the BH RIMS tube, though at the cost of dozens of hours to build and at the benefit of building in a lot of features specific to my system.

augiedoggy

Well-Known Member

See this statement right here is key because it touches on a bigger question here. Why do you believe a heated surface directly toughing the wort is bad? You dont need to use a 4500w or 5500w element in a rims its actually 4-5 times more than needed.Great reminder.

The reasoning for this is that no wort ever touches a heating element, nor does it ever enter the RIMS tube. That means I will rarely, if ever, have to clean the RIMS element or tube, since it's only ever touching water. Similarly, I have one chugger which does the bulk of the work and can handle the wort, but only a little brown $20 12v is needed for the RIMS water. Bonus: no chance of scorching if I screw up. Plus I get the benefits of HERMS (heating my sparge water and mash to sparging temps simultaneously). Extra bonus: if this system turns out to suck, I haven't bought or made anything that can't be used some other way, so no waste.

.

The thing is, There's nothing actually wrong with wort touching heating elements.. especially if they are ULWD elements.. The heat from those is dispersed more gently than many direct fire burners. This is a fear many have based on myths and improperly matched components from people that tried to use HWD elements or way too much flow through their rims causing stuck sparges and stalled rims flow. if your system Is built correctly to take this stuff into account you can have all the benefits of electric and rims without fear of any of the stygmas that accompany them from the poorly designed and implemented setups..

Not that theres anything at all wrong with your setup I just dont see the foundation of your motives for building it that way.

I also dont have to clean my rims often because I used such a low watt Density element in my rims that it gets ZERO buildup on it after brewing and rinses clean with pbw/water every few brews. (I built it to come apart and be wiped off and cleaned in under 1 minute if wanted though.

Since I use a 1800w 7amp 240v rims I can also step mash with over 2 degree a minute rise from my rims tube and compensate and correct for dough in temp miscalculations in minutes without having to wait for what seemed like eternity for my herms tank to catch up and to have to keep mixing the herms water with a pump or stirrer to prevent stratification and the wildly inconsistent temps that followed. theres also zero chance of any scorching because my element has so much surface area vs wattage..

shoo

Well-Known Member

- Joined

- Aug 14, 2017

- Messages

- 93

- Reaction score

- 28

See this statement right here is key because it touches on a bigger question here. Why do you believe a heated surface directly toughing the wort is bad?

I don't. I understand that scorching isn't really an issue as long as you build/tune it right. Mine is even insanely low watt density, so I am not even a little concerned (I'm using an already ULWD 5500w @240v element at 120v, so 1375w in total it's super low watt density).

The justification in my case is cost, convenience, and versatility. I made super on-the-cheap RIMS tube, which is a giant PITA to take apart to clean and put back together. Every few brews would be too much to make it worth it. I can also use a dedicated cheap pump for this too, since I don't need to worry about particles or sugars gumming up my pump. That is also convenient for doing some sous vide, since I don't have to get my chugger out and listen to it chug for 3 hours every time I want to use it.

The other big benefit in my case is sparge water and mashing temps ala HERMS. I don't have access to the kind of power that would let me heat sparge water on-the-fly. I'm using a regular old kitchen with a mediocre electric stovetop.

Edit: And of course, as mentioned, it may turn out that this is all just too complicated. But if it is, I can just use the RIMS tube as a regular RIMS tube, and I didn't waste any money in the process. But if it works as intended, it could save a lot of time and greatly increase the precision and automation of my mash/sparge process.

Double edit:

Since I use a 1800w 7amp 240v rims I can also step mash with over 2 degree a minute rise from my rims tube and compensate and correct for dough in temp miscalculations in minutes without having to wait for what seemed like eternity for my herms tank to catch up and to have to keep mixing the herms water with a pump or stirrer to prevent stratification and the wildly inconsistent temps that followed. theres also zero chance of any scorching because my element has so much surface area vs wattage..

The water enters my HLT/BK via a whirlpool arm, so it's constantly recirculating through a dedicated tiny pump attached to my RIMS tube. And it sits on top of the stove, so if/when I need more power to step up temperature, I have the added power of the stove to heat both (albeit manually).

The whirlpool arm and heat exchanger all serve a secondary purpose. My HLT is the BK, so the whirlpool arm also lets me do a regular whirlpool. I could even do a precision hop stand if I really wanted to, by placing the immersion chiller in the BK, and using my MT as a sort of reverse HLT using the RIMS tube to power it. That, and of course I can use the immersion chiller to recirculate cold water through the immersion chiller via the tiny pump while recirculating the wort through the chugger/whirlpool arm, acting as a sort of counterflow chiller. In theory, I can do all kinds of crazy stuff without having to have dedicated anything.

In theory, this system gets a lot of the best of both RIMS and HERMS. In theory.

SleepyCreekBrews

Well-Known Member

HERMs is Rube Goldberg. But some people like complexity. I've never scorched wort in my RIMs tube. The key to happy RIMs is a mash tun and false bottom combo that will get you a good flow rate.

This is true about the flow rate. combine that with an ULWD element running on 120VAC, and that's the recipe for success. I firmly believe there's no reason for a RIMS tube to run on 240VAC, way too much power.

My RIMs runs at both 120 and 240 depending on the mode. I mash at 120V. That said, I think limiting the output duty cycle to no more than 25% when at 240V theoretically matches the max power output at 120V.

HERMs is Rube Goldberg. But some people like complexity. I've never scorched wort in my RIMs tube. The key to happy RIMs is a mash tun and false bottom combo that will get you a good flow rate.

I don't agree with this at all. Rube Goldberg is additional complexity for no benefit or even positive detriment. There are logical pros and cons to both systems.

A HERMS coil and install is about the same cost as a well made RIMS with element. If you have a gas fired HLT, a RIMS makes a little more sense because it's controllable without going full electric. If you already have an electric HLT on a controller, the HERMS is a no brainer. You already have the heat source and controller.

And seriously, a passive coil you pump through is more complicated than a RIMS with separate power and electrics?

augiedoggy

Well-Known Member

point made but a herms coil has time limitations involved with it so its not a no brainer for everyone....I don't agree with this at all. Rube Goldberg is additional complexity for no benefit or even positive detriment. There are logical pros and cons to both systems.

A HERMS coil and install is about the same cost as a well made RIMS with element. If you have a gas fired HLT, a RIMS makes a little more sense because it's controllable without going full electric. If you already have an electric HLT on a controller, the HERMS is a no brainer. You already have the heat source and controller.

And seriously, a passive coil you pump through is more complicated than a RIMS with separate power and electrics?

Besides the fact that its too slow for very effective step mashing in most cases, With my rims I can be mashing at 152 while my sparge water is independently heating up to 170 degrees so I dont have to wait or ramp up my mash early.

also in larger systems this allows a person to add more water to an undersized HLT and heat it up while mashing... (I visited a brewery just last week where the owner had to but in a bigger electrical service to be able to run his 3bbl BK at the same time as his Herms/hlt to help get around waiting hrs by heating the water in the BK then transferring to the HLT..

You have to have a pid and element either way.... Honestly a person could use the pid from the BK for the rims and just switch them over to the rims when needed and have the temp probe calibrated for the rims since its not important in the BK...

Like mentioned earlier theres a lot of ways to implement this if one wants.. but all that aside the performance and function of a properly implemented RIMS outperforms a properly implemented HERMS. all the negatives are in the added cost to build or improper mash tun drainage setups (which really needs to be addressed in either case).

This thread has totally been taken of topic btw..as theres many herms vs rims debates here already and they are going to have about as much effect as democrats vs republican debates...

I agree that RIMS is faster due to the isolated mass of just the mash but I also think a lot of undue stress is put on making razor sharp temp changes. The enzymes don't know they've gone through military precision or an averaged out ramp over the desired temp ranges. Even so, if you want more stepping and less ramping, you can pause the recirc and let the HLT come up to the next large delta then pump again. I wouldn't.

On a simple 30 amp powered 3 vessel system, you can get by with a very simple single EZboil, one SSR and either a simple selector switch or even swapping element plugs with a HERMS. With an all electric RIMS system, you'll need two controllers, two SSRs minimum. It's not a big deal or overly complex, but you can see how calling the HERMS more complicated sounds a little off.

I would always run up the HLT controller to 170 starting at 40 minutes into the mash and end the rest when it got there. Now you're at sparge temps and by the time the BK element is covered, you don't need the HLT to fire anymore anyway.

On a simple 30 amp powered 3 vessel system, you can get by with a very simple single EZboil, one SSR and either a simple selector switch or even swapping element plugs with a HERMS. With an all electric RIMS system, you'll need two controllers, two SSRs minimum. It's not a big deal or overly complex, but you can see how calling the HERMS more complicated sounds a little off.

I would always run up the HLT controller to 170 starting at 40 minutes into the mash and end the rest when it got there. Now you're at sparge temps and by the time the BK element is covered, you don't need the HLT to fire anymore anyway.

Silentdrinker

Well-Known Member

- Joined

- Nov 7, 2014

- Messages

- 409

- Reaction score

- 184

I’d say definitely rims over Herms. I have the rims rocket. It’s fine. I’m not unsatisfied with the results. I just feel like it’s kind of a dumb design and sort of wish I went a different direction. It’s the only rims I’ve used.

I feel like it’s super cumbersome especially how the plug is on the bottom. And I feel it’s just too big for the purpose. Since it pushes from bottom up, I end up having to drain a lot out to avoid waste.

I wish I built my own or got one that’s a simple tube so the chamber is smaller. It works fine but I wouldn’t bother wasting money on it. If you got a deal that’s another story. I think the controller and temp sensors are more important things to focus on. I built my controller and temp sensors, so I’m happy with those.

I don't agree that it’s 4-5x more than needed. Mine is 4000 watts ultra low density. I don't have scortching or build up issues at all. But even at 4k watts, step mashing is slow. I don't do it much but there have been times I want to do a ferulic acid rest at 113f to get more clove phenol. Trying to get from 113 to 153 can take time. I add boiling water but I still feel like a lower wattage element would case more frustration.

I feel like it’s super cumbersome especially how the plug is on the bottom. And I feel it’s just too big for the purpose. Since it pushes from bottom up, I end up having to drain a lot out to avoid waste.

I wish I built my own or got one that’s a simple tube so the chamber is smaller. It works fine but I wouldn’t bother wasting money on it. If you got a deal that’s another story. I think the controller and temp sensors are more important things to focus on. I built my controller and temp sensors, so I’m happy with those.

See this statement right here is key because it touches on a bigger question here. Why do you believe a heated surface directly toughing the wort is bad? You dont need to use a 4500w or 5500w element in a rims its actually 4-5 times more than needed.

I don't agree that it’s 4-5x more than needed. Mine is 4000 watts ultra low density. I don't have scortching or build up issues at all. But even at 4k watts, step mashing is slow. I don't do it much but there have been times I want to do a ferulic acid rest at 113f to get more clove phenol. Trying to get from 113 to 153 can take time. I add boiling water but I still feel like a lower wattage element would case more frustration.

I'm actually kind of backwards compared to most, I started with old traditional 2 vessel, then gas brew in a bag, then electric brew in a bag, then single pot rims with a bag, then 2 vessel rims with 2 pumps and I thought I was done but over and over I kept burning my element.

I actually have a scorch mark inside my rims tube that won’t clean and ruined 2 elements, so I tried herms and now I don't have to sit in front of it and that’s a big plus for me, I don't have too but I do fly sparg and it does take a few hours longer then I did with the rims but the best part is no chance of anything going wrong so now I can have a beer or two while brewing.

All I can say is I’ve done it all and it’s a personal preference which is the best depending what you want, you have to consider ease of use or time or cost, they all come into play here

I actually have a scorch mark inside my rims tube that won’t clean and ruined 2 elements, so I tried herms and now I don't have to sit in front of it and that’s a big plus for me, I don't have too but I do fly sparg and it does take a few hours longer then I did with the rims but the best part is no chance of anything going wrong so now I can have a beer or two while brewing.

All I can say is I’ve done it all and it’s a personal preference which is the best depending what you want, you have to consider ease of use or time or cost, they all come into play here

The primary advantage of HERMS over RIMS is that the heating can be done more gently and you can guarantee that you won't have even localized heating above critical enzyme temps. This is a benefit, but IMHO, not only worth the hassle of dealing with 3 vessels. The cost of that gentleness comes in step times though.

This echoes my sentiments on the RR perfectly. It's really a randall that they just so happened to figure out can dual purposed as a RIMS tube by putting a heating element in it. I find it awkward to use and clean, but it does work.

I use it for mashing in at precise temps and when i'm done transferring from the MLT i have a low point drain to clear it out. Since it holds more than a quart all that liquid goes into a bucket, then the BK. I consider that volume when designing recipes.

I have the rims rocket. I feel like its super cumbersome especially how the plug is on the bottom. And I feel its just too big for the purpose. Since it pushes from bottom up, I end up having to drain a lot out to avoid waste.

This echoes my sentiments on the RR perfectly. It's really a randall that they just so happened to figure out can dual purposed as a RIMS tube by putting a heating element in it. I find it awkward to use and clean, but it does work.

I use it for mashing in at precise temps and when i'm done transferring from the MLT i have a low point drain to clear it out. Since it holds more than a quart all that liquid goes into a bucket, then the BK. I consider that volume when designing recipes.

augiedoggy

Well-Known Member

This is true about the flow rate. combine that with an ULWD element running on 120VAC, and that's the recipe for success. I firmly believe there's no reason for a RIMS tube to run on 240VAC, way too much power.

Mine runs on 240v and it's only 1800w so voltage doesn't mean anything other than I use less amps this way..

augiedoggy

Well-Known Member

Id say definitely rims over Herms. I have the rims rocket. Its fine. Im not unsatisfied with the results. I just feel like its kind of a dumb design and sort of wish I went a different direction. Its the only rims Ive used.

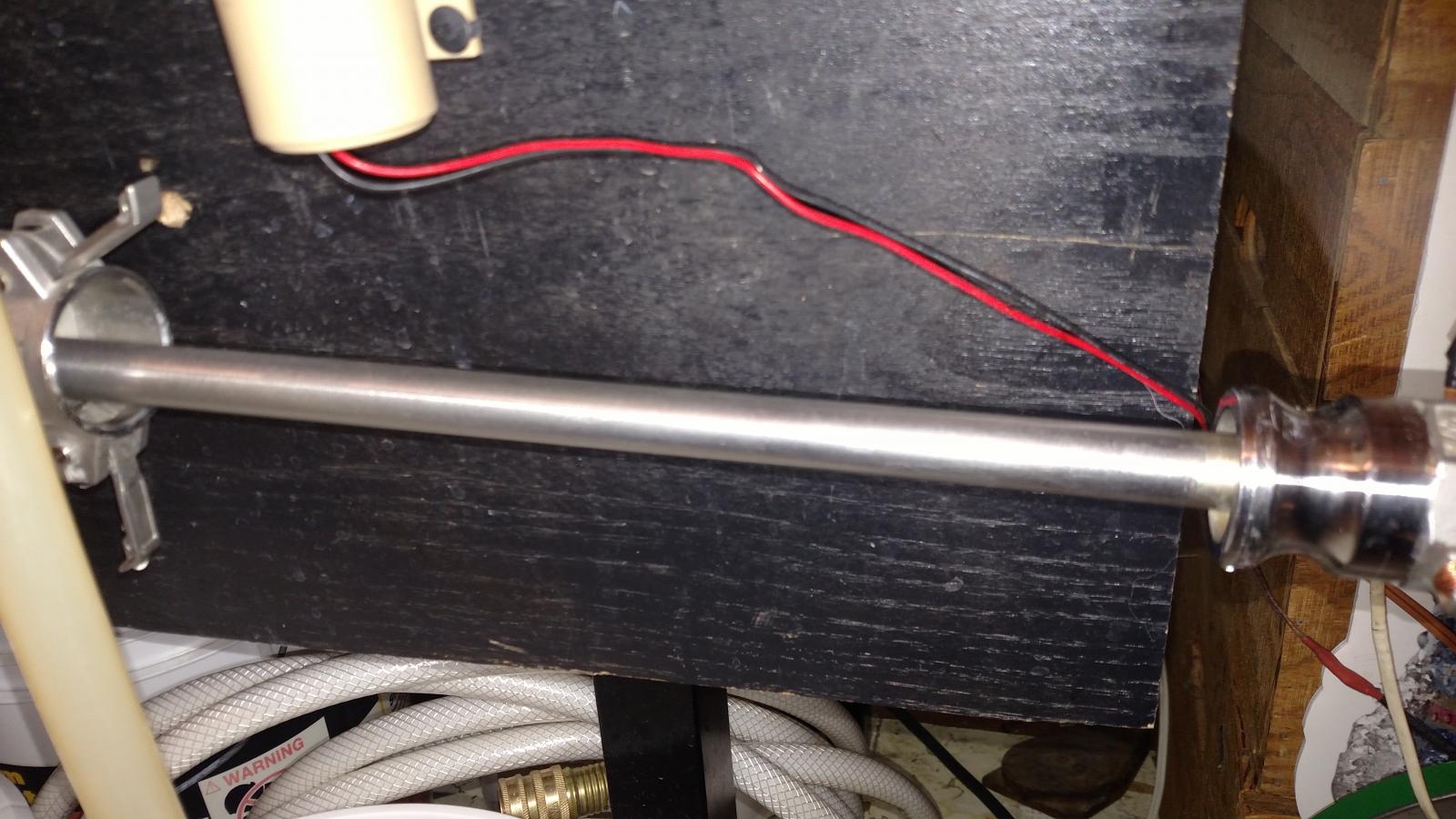

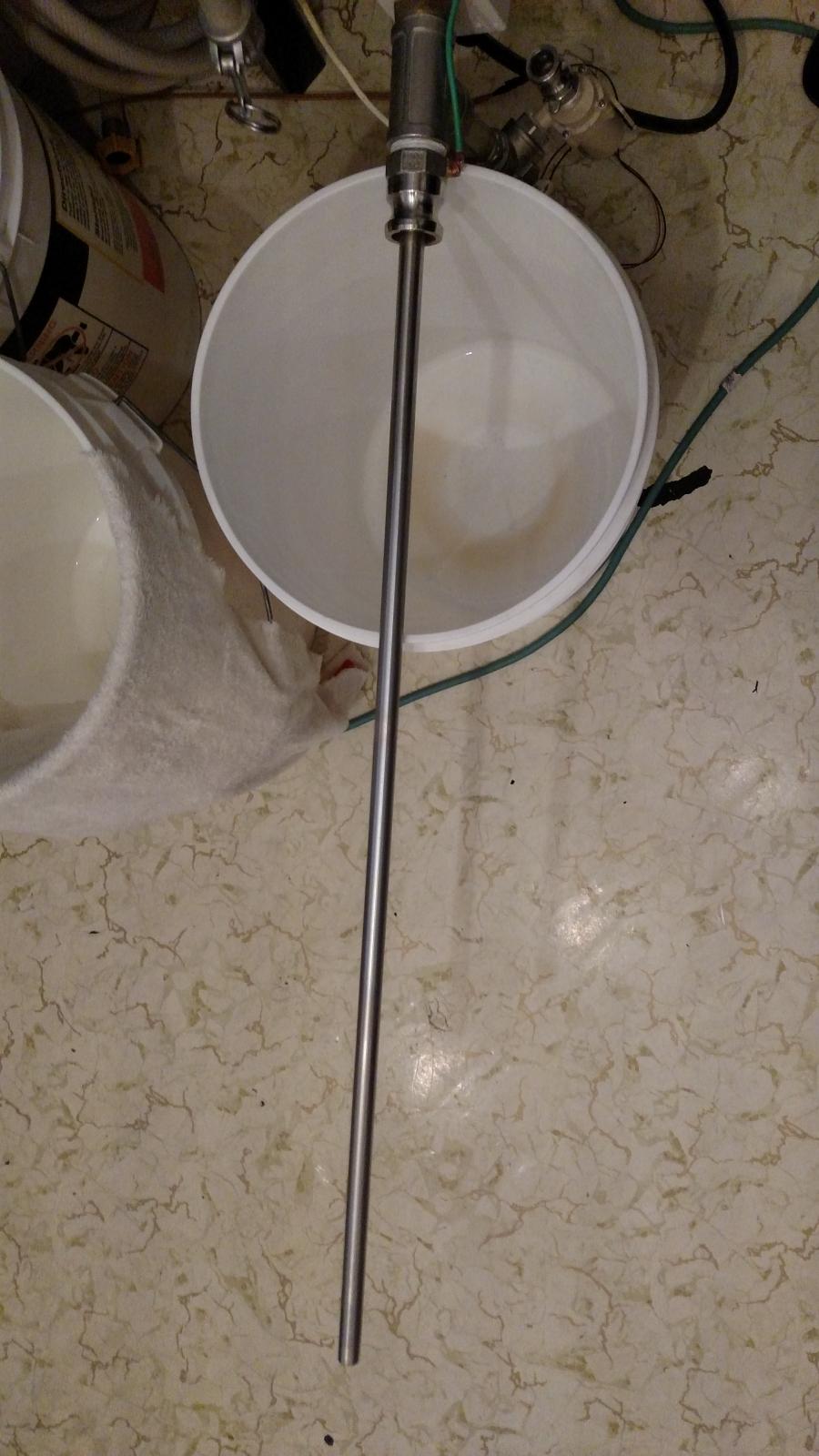

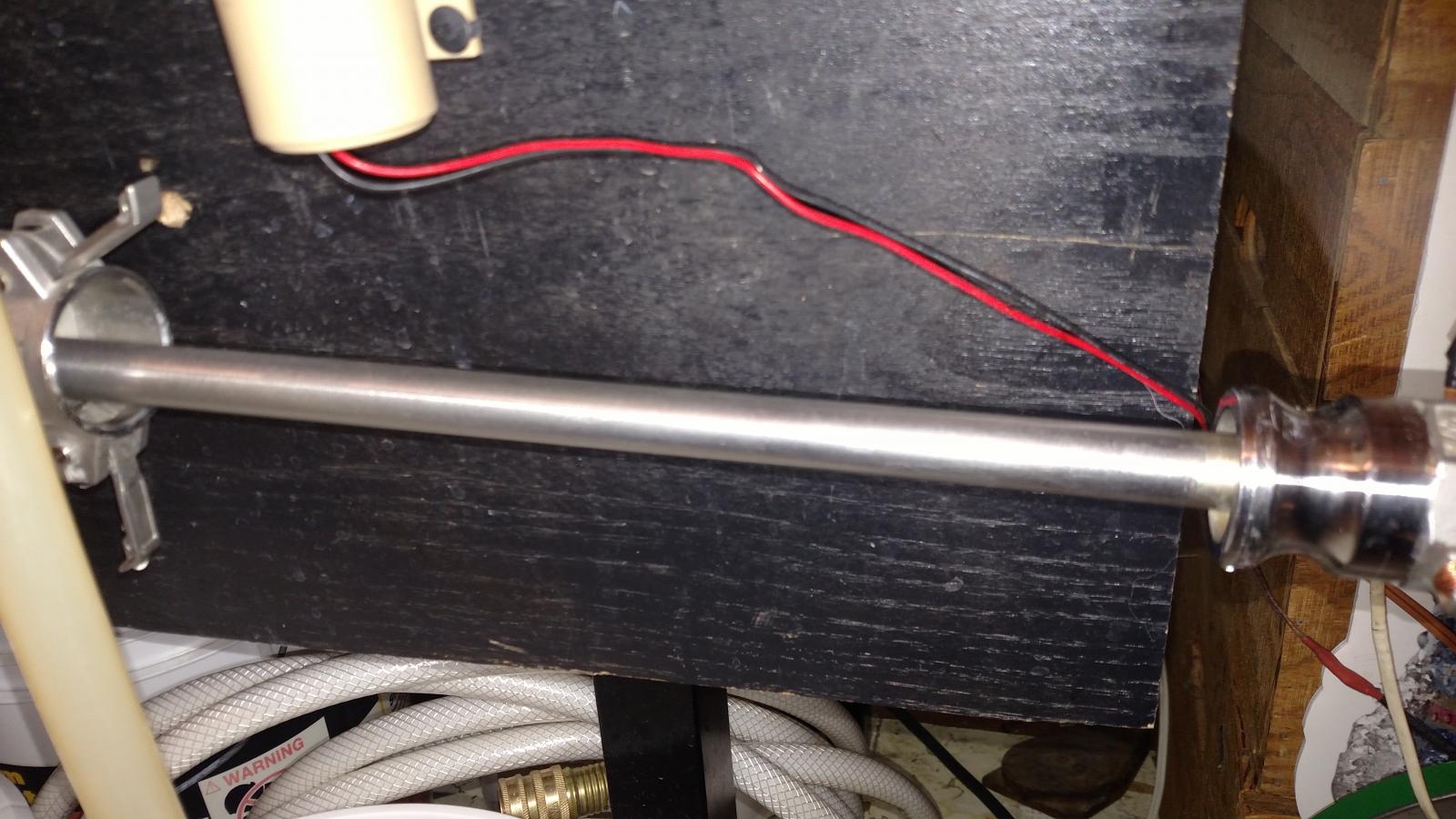

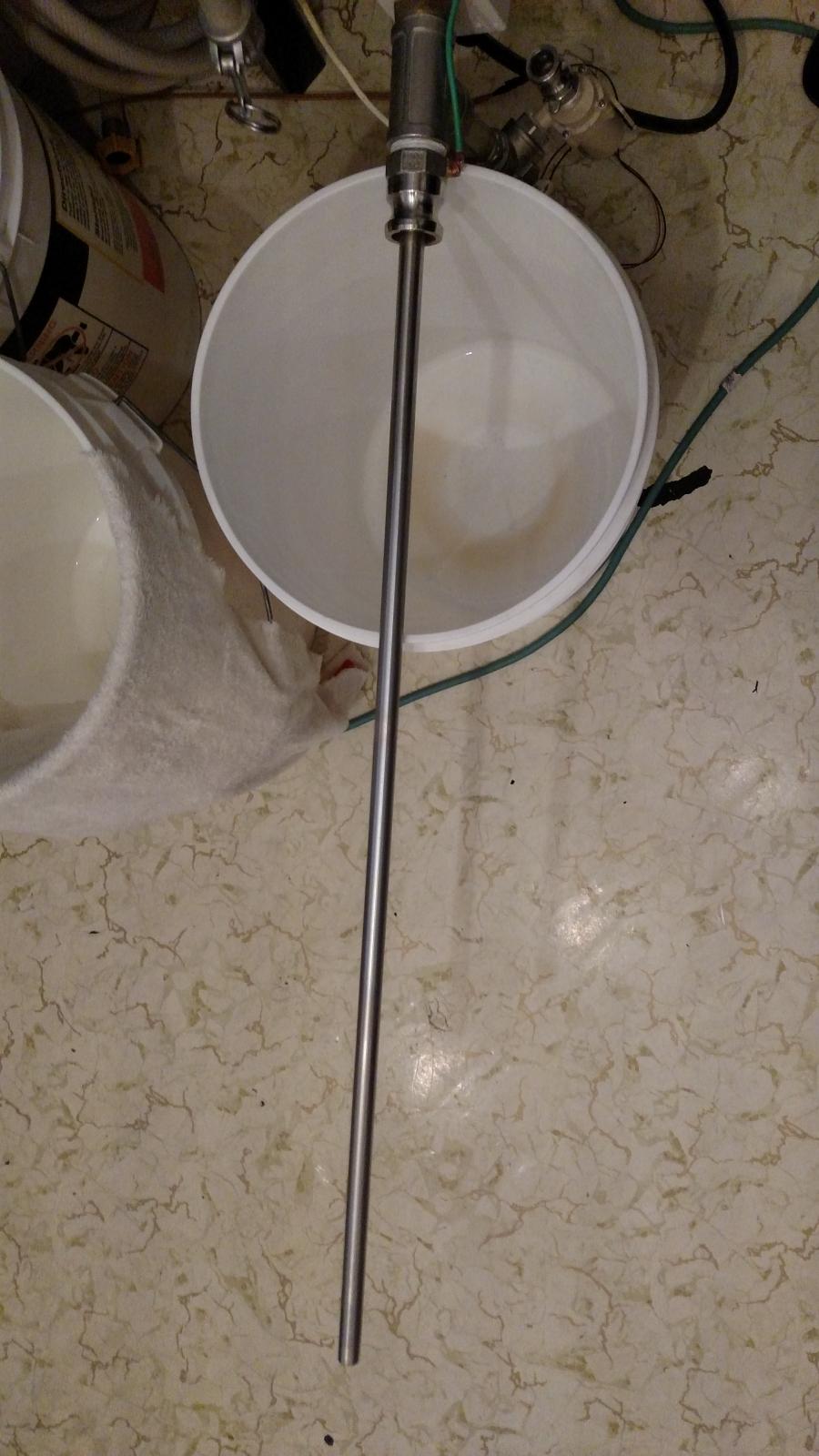

View attachment 417805

I feel like its super cumbersome especially how the plug is on the bottom. And I feel its just too big for the purpose. Since it pushes from bottom up, I end up having to drain a lot out to avoid waste.

I wish I built my own or got one thats a simple tube so the chamber is smaller. It works fine but I wouldnt bother wasting money on it. If you got a deal thats another story. I think the controller and temp sensors are more important things to focus on. I built my controller and temp sensors, so Im happy with those.

I don't agree that its 4-5x more than needed. Mine is 4000 watts ultra low density. I don't have scortching or build up issues at all. But even at 4k watts, step mashing is slow. I don't do it much but there have been times I want to do a ferulic acid rest at 113f to get more clove phenol. Trying to get from 113 to 153 can take time. I add boiling water but I still feel like a lower wattage element would case more frustration.

How slow is slow? My little 1800w rims increases about 2.5 degree a minute at 2 gpm flow rate. If your flow rate is too fast efficiency suffers.

- Joined

- Dec 5, 2007

- Messages

- 1,719

- Reaction score

- 759

I like my HERMS fwiw. If my pump stops pumping I cannot scortch any wort. I do Hockhurtz mashes or other step mashes without a problem.

augiedoggy

Well-Known Member

Don't take this the wrong way but something obviously wasn't right with your Rims setup. You based your opinion of all Rims based off bad experiences with a flawed design. You should never get scorching in a rims and they can be made where there's no concern of it ever happening.I'm actually kind of backwards compared to most, I started with old traditional 2 vessel, then gas brew in a bag, then electric brew in a bag, then single pot rims with a bag, then 2 vessel rims with 2 pumps and I thought I was done but over and over I kept burning my element, I actually have a scorch mark inside my rims tube that wont clean and ruined 2 elements, so I tried herms and now I don't have to sit in front of it and thats a big plus for me, I don't have too but I do fly sparg and it does take a few hours longer then I did with the rims but the best part is no chance of anything going wrong so now I can have a beer or two while brewing. All I can say is Ive done it all and its a personal preference which is the best depending what you want, you have to consider ease of use or time or cost, they all come into play here

augiedoggy

Well-Known Member

I like my HERMS fwiw. If my pump stops pumping I cannot scortch any wort.

Same here with my Rims... Not only will the $10 flow switch wired to my SSR cut the heat but even if it didn't the element density is just too low at 36" length it heats so gently it's like a herms only quicker.

Everyone seems to assume all rims have to be made the same way with the same 3-4 element choices but they don't.

I actually like the rims the best and yes if I were to do it again I would put some safety switches in there to not let this happen but you live and learn and I still have all my vessels but I spent the money on a full blown kal clone, why not use it

augiedoggy

Well-Known Member

I actually like the rims the best and yes if I were to do it again I would put some safety switches in there to not let this happen but you live and learn and I still have all my vessels but I spent the money on a full blown kal clone, why not use it

Understood... It would still drive me nuts to figure out why you had scorching..

Silentdrinker

Well-Known Member

- Joined

- Nov 7, 2014

- Messages

- 409

- Reaction score

- 184

How slow is slow? My little 1800w rims increases about 2.5 degree a minute at 2 gpm flow rate. If your flow rate is too fast efficiency suffers.

I do 10-11g batches almost exclusively sometimes maybe 15g once in a while

At 5500w it takes over 30min to heat 13g strike from 68f to 163f.

well the issue was just my negligence, and not switching the right buttons correct, bad cavitation issues and pumps stopping but if I had safety level switches it would be fixed, I had no idea those existed at the time

Silentdrinker

Well-Known Member

- Joined

- Nov 7, 2014

- Messages

- 409

- Reaction score

- 184

I like my HERMS fwiw. If my pump stops pumping I cannot scortch any wort. I do Hockhurtz mashes or other step mashes without a problem.

A properly set up rims should never scortch. If a pump stops flowing, the temp probe will cut power to the element.

i get scorching on my rims rocket if i turn the element on in the first 60 seconds of recirculation. i start recirculation slow though (0.5 GPM). This happens because the flow rate is so low and the temp sensor hasn't had time to reach the real temp.

The solution is easy though. Wait the 2 mins or so for the grain bed to settle, crank it up to 2 GPM, THEN start the controller....

As long as you have sufficient flow for the power you are delivering you won't scorch. Even then i've had nearly black elements on a Helles, and the Helles wort was as light as you could imagine and had no taste of burning.

The solution is easy though. Wait the 2 mins or so for the grain bed to settle, crank it up to 2 GPM, THEN start the controller....

As long as you have sufficient flow for the power you are delivering you won't scorch. Even then i've had nearly black elements on a Helles, and the Helles wort was as light as you could imagine and had no taste of burning.

A properly set up rims should never scortch. If a pump stops flowing, the temp probe will cut power to the element.

you cant predict cavitation or bump issues, it just happens, I think a person should replace the impellers at least every 2 years if not every year, that solved my problem with pumps

augiedoggy

Well-Known Member

I also do 11 gallon brews,, I dont use my rims to heat from 68 degrees though, I use the HLT element to heat my strike water.I do 10-11g batches almost exclusively sometimes maybe 15g once in a while

At 5500w it takes over 30min to heat 13g strike from 68f to 163f.

augiedoggy

Well-Known Member

I'm going on 4 years with the same $18 DC pumps plumbed into my system with no noticeable wear... I designed my mash tun with a second stainless braid filter under my false bottom which has eliminated any slow flow issues on everything but oatmeal stouts where I actually had to use rice hulls (used them twice)...you cant predict cavitation or bump issues, it just happens, I think a person should replace the impellers at least every 2 years if not every year, that solved my problem with pumps

So you can design the equipment to make this stuff a non issue... If you are wearing out impellers it sounds like your pump is working too hard to me but I never used those big pumps so Im not sure.. I also have no issues turning my rims on even before I start flow thanks to my flow switch.

augiedoggy

Well-Known Member

I brewed a Belgian Dubbel last night.. When I finished I ran warm water through my rims and plate chiller for about 20 seconds until I was out of water in my HLT... this is the state of my element directly after brewing with only that 20 second rinse. as you can see its completely clean with no film whatsoever. This is due to the very low watt density. this also eliminates the "shock treatment" Bobby was talking about... I average 86% efficiency on this system all day long so It must be doing something right... The Belgian Dubbel I brewed last night was from Jamil and John Palmers "brewing classic styles" and even though the recipe called for .5lbs of cane sugar on top of the belgian syrup I found I more than hit my numbers without adding it at all.(hopefully its not needed to dry the beer out but im already at the potential for 8.7% abv.)

processhead

Well-Known Member

you cant predict cavitation or bump issues, it just happens, I think a person should replace the impellers at least every 2 years if not every year, that solved my problem with pumps

My experience with RIMS pumps may be an exception, but impeller/ head wear has never been an issue.

I have close to 8 years on my March pump with the original head and impeller.

My experience has been that all pump operational problems could be traced back to improper pump placement, poor piping layout, or air leaks in pump suction piping.

Hard piping everything goes a long way to eliminate air leaks. Suction air leaks can be tough to track down, but all quick-connect fitting should be suspect as most seal best in positive pressure systems, which the suction side of the pump is not.

Keeping ALL suction side piping between the MLT and the pump inlet in a continuous downward gradient will practically eliminate air locking issues.

Keeping pump suction side piping runs as short, direct and vertical as possible, and of sufficient inside diameter is one of the best things you can do for your RIMS to ensure reliable operation.

- Joined

- Dec 5, 2007

- Messages

- 1,719

- Reaction score

- 759

A properly set up rims should never scortch. If a pump stops flowing, the temp probe will cut power to the element.

What percentage of RIMS systems would you estimate are properly set up?

Most of the ones I see written about on HBT have no flow meters or pump monitors. A cursory search for RIMS SCORTCHED WORT on HBT found several anecdotal reports.

augiedoggy

Well-Known Member

What percentage of RIMS systems would you estimate are properly set up?

Most of the ones I see written about on HBT have no flow meters or pump monitors.

I believe what he meant was the temp probe should be very close to the end of the heating element... almost touching it... if this simple thing is done the rims will turn off almost immediately once flow stops. (because the temp probe is effectively doing its job) no fancy stuff needed... I added my flow switch because I forget to turn off my rims so it does it for me and the redundant safety doesnt hurt.

Your typical commonly sold out of the box rims setup usually doesnt allow this with a very powerful element which stops way short of filling the length of the tube.. Those rims kits are designed for the sellers sake by simply using 2 cheap offset tees used in dairy and pharmaceutical applications. (Well they were cheap before people stated using them for Rims). and the most common off the shelf parts. The repurposed randell that blichmann sells as a rims is no exception they work but they are hardly ideal.. more of a compromise to build cheap and sell. My rims cost me about $100-150 to build if I recall correctly

Many brewers use mismatched rims parts and use incorrect flow speeds thinking faster and bigger is always better which causes channeling and more often stuck MT drains..

What we really need is for a vendor to design and sell a rims kit that takes this into account.(are you listening Bobby since your usually the one developing and introducing better new equipment ).

Maybe provide a flowmeter (they are as little as $15 shipped) with flow recommendations... Its true everyones systems are a bit different as far as mash tuns and drainage but then you would see a lot less mistakes and scorching as a result... Just Because Herms is more "foolproof", doesnt necessarily make it better overall.

The beauty of our hobby is that there are so many different brewing options to cater to every brewer's individual preference, concerns, goals, budgets, and time. This means we also all have very strong opinions about our preferences and approach.

Both RIMs and HERMs can work fantastically and produce wonderful beer assuming you think through your design, element types and sizes, and manage flow rates. Many of you who posted here have great examples of both systems that I admire.

I took the hybrid route of a HEX. This meant added equipment, plumbing, elements, electronics, and cost. To me it's a marriage of what makes RIMs and HERMs both great but also provides me with additional functionality (ie 2 elements heating strike, quick mash step, maintain whirlpool temp, wort chiller, easy clean up, etc) beyond just mashing. Cost and complexity alone makes it overkill for most people, but at the end of the day - like most of you who feel strongly about the benefits of RIMS over HERMs or vice-versa -it meets my objectives.

I am not advocating HEX for everyone, just throwing it out there to the OP as another option to consider in addition to RIMs or HERMs.

Both RIMs and HERMs can work fantastically and produce wonderful beer assuming you think through your design, element types and sizes, and manage flow rates. Many of you who posted here have great examples of both systems that I admire.

I took the hybrid route of a HEX. This meant added equipment, plumbing, elements, electronics, and cost. To me it's a marriage of what makes RIMs and HERMs both great but also provides me with additional functionality (ie 2 elements heating strike, quick mash step, maintain whirlpool temp, wort chiller, easy clean up, etc) beyond just mashing. Cost and complexity alone makes it overkill for most people, but at the end of the day - like most of you who feel strongly about the benefits of RIMS over HERMs or vice-versa -it meets my objectives.

I am not advocating HEX for everyone, just throwing it out there to the OP as another option to consider in addition to RIMs or HERMs.

I think @Bobby_M made some good points above... at the end of the day RIMS will generally require a 3rd element (with associated electronics) if you have an HLT. This is one of the reasons I personally went with high/low power RIMS and direct sparge water heating. It does take more controls to get right but keeps the design to 2 elements and two kettles. Like @BrewKaiser mentioned, different approaches are what make the hobby cool and personal preference lets us explore different pathways.

augiedoggy

Well-Known Member

I agree, My point of view was more geared towards the common beliefs that rims are less relable and have "issues"... Those are simply the result of poorly designed setups and not an actual trait of a rims system whereas I dont know of any herms system that can perform as quickly as a rims myself regardless of how well its designed... Maybe with additional hardware and heating elements

I know this is a bit of a stretch but I imagine people had similar debates about the automobile vs a horse when they first came onto the scene. since they both had their ups and downs and early vehicles had a lot of downs..

Eventually more commonly available better engineered cars made the comparison more of a moot point for most. Who knows maybe simpler more foolproof rims will come into the marketplace and be a game changer like electric is over propane for many..

I know this is a bit of a stretch but I imagine people had similar debates about the automobile vs a horse when they first came onto the scene. since they both had their ups and downs and early vehicles had a lot of downs..

Eventually more commonly available better engineered cars made the comparison more of a moot point for most. Who knows maybe simpler more foolproof rims will come into the marketplace and be a game changer like electric is over propane for many..

Silentdrinker

Well-Known Member

- Joined

- Nov 7, 2014

- Messages

- 409

- Reaction score

- 184

What percentage of RIMS systems would you estimate are properly set up?

Most of the ones I see written about on HBT have no flow meters or pump monitors. A cursory search for RIMS SCORTCHED WORT on HBT found several anecdotal reports.

You don't need to worry about flow or the pump to failsafe the RIMS. A flow meter would be more important to avoid dry firing the RIMS element.

If the liquid in the rims gets stalled, the temp probe will detect the temp and shut off the element. So the liquid could never reach more than 153f if my controller is set for 153f.

If people don't set it up properly, it's on them. But that doesn't mean HERMS is better due to this scenario.

I have my sensor in a T fitting at the exit of the rims so the probe is inside the chamber. I then built a long sensor probe that I'm able to move around. It allows me to place it anywhere inside the mash bed just to monitor the temp throughout the bed.

My process uses the RIMS temp probe for the automation.

So if the flow ever stops, that temp probe won't allow the rims to continue to heat past the set temp.

Now if a process relies on the temps in the mash, you have a different story. Once flow stops, the bed will continue to get cold so the element continues to build heat. That's not a smart setup.

I put a sight glass on my mash tun with the port just below the false bottom. It works as a great (relative) vaccum gauge to show RIMS flow. I wait till the column stabilizes before turning on the RIMS. Sometimes this occurs when pump is full open, sometimes not (rice, corn, oats...)

Similar threads

- Replies

- 2

- Views

- 421