sensei247

Active Member

- Joined

- Jun 4, 2020

- Messages

- 38

- Reaction score

- 2

Hi All- I have finally decided to pull the trigger on automating my brewhouse. Starting with the cold side as I am a few months out from ordering my LODO Stout kettles. Cold side seems like an easier place to shake off the rust from my (light) comp sci/electrical eng university studies....

Overall goal: automate cold side fermentation end to end. "End to end" = starts when wort leaves the BK and enters FV THROUGH to keg transfer and finally spunding (if desired). I am also trying to manage vacuum issues by integrating CO2 solenoid to adjust FV pressure when temperature drops and pressure approaches vacuum.

This isn't a fully complete build as I plan to add on to this in the future (e.g. automated dry hopping, automated yeast dumps, etc.). Trying to keep this in mind with the larger relay, terminal, etc. buses.

--Call it overkill because it is.--

3 of main concerns right now include:

1) HV: First time working and integrating high voltage through breakers, PSUs, downstream electronic components, etc. In this case, 110V input voltage to panel. - want to ensure this wiring is correct (left side of image)

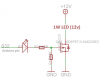

2) Electronic components: First time working with MOSFETs and flyback diodes. Not sure the relay is setup correctly either- want to ensure solenoid wiring and other sensor wiring is correct (right side of image)

3) Safety: Overall, is this something I can safely run without risk of electrocution, fire, etc.? - are there any other safety components I am missing or not wired in correctly?

----------------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------------------

Master schematic:

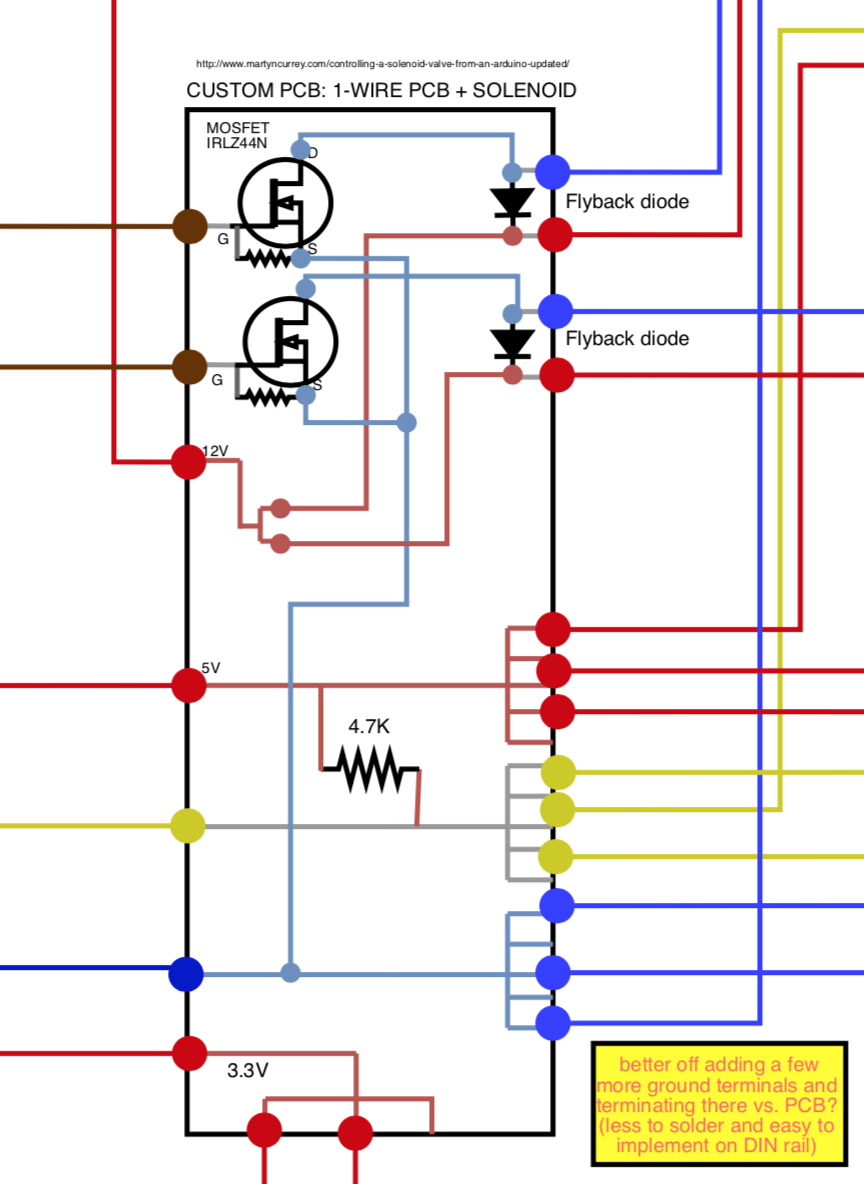

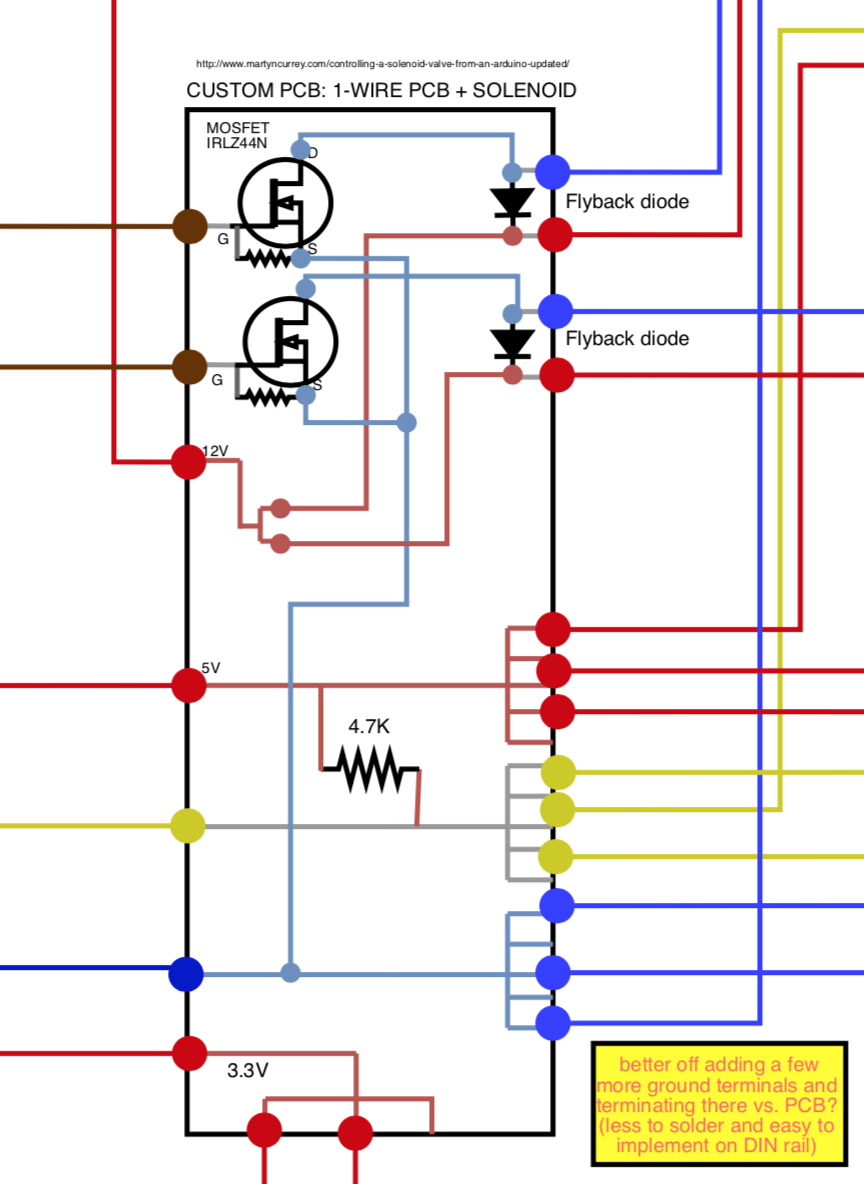

Close up - custom circuit board:

Overall goal: automate cold side fermentation end to end. "End to end" = starts when wort leaves the BK and enters FV THROUGH to keg transfer and finally spunding (if desired). I am also trying to manage vacuum issues by integrating CO2 solenoid to adjust FV pressure when temperature drops and pressure approaches vacuum.

This isn't a fully complete build as I plan to add on to this in the future (e.g. automated dry hopping, automated yeast dumps, etc.). Trying to keep this in mind with the larger relay, terminal, etc. buses.

--Call it overkill because it is.--

3 of main concerns right now include:

1) HV: First time working and integrating high voltage through breakers, PSUs, downstream electronic components, etc. In this case, 110V input voltage to panel. - want to ensure this wiring is correct (left side of image)

2) Electronic components: First time working with MOSFETs and flyback diodes. Not sure the relay is setup correctly either- want to ensure solenoid wiring and other sensor wiring is correct (right side of image)

3) Safety: Overall, is this something I can safely run without risk of electrocution, fire, etc.? - are there any other safety components I am missing or not wired in correctly?

Any chance you can offer any and all feedback on my fermentation controller wiring diagram? Thanks in advance

----------------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------------------

Master schematic:

Close up - custom circuit board:

Last edited: