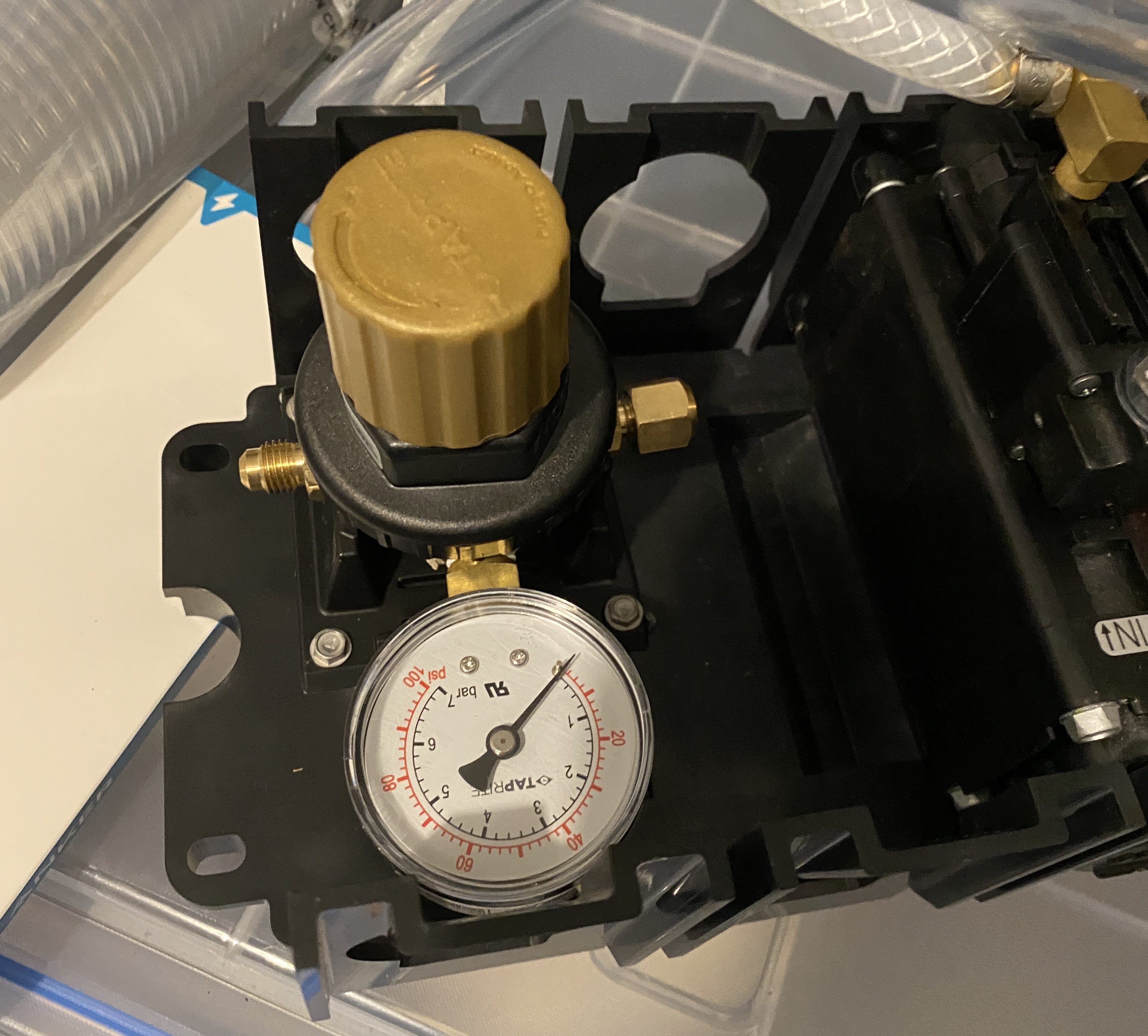

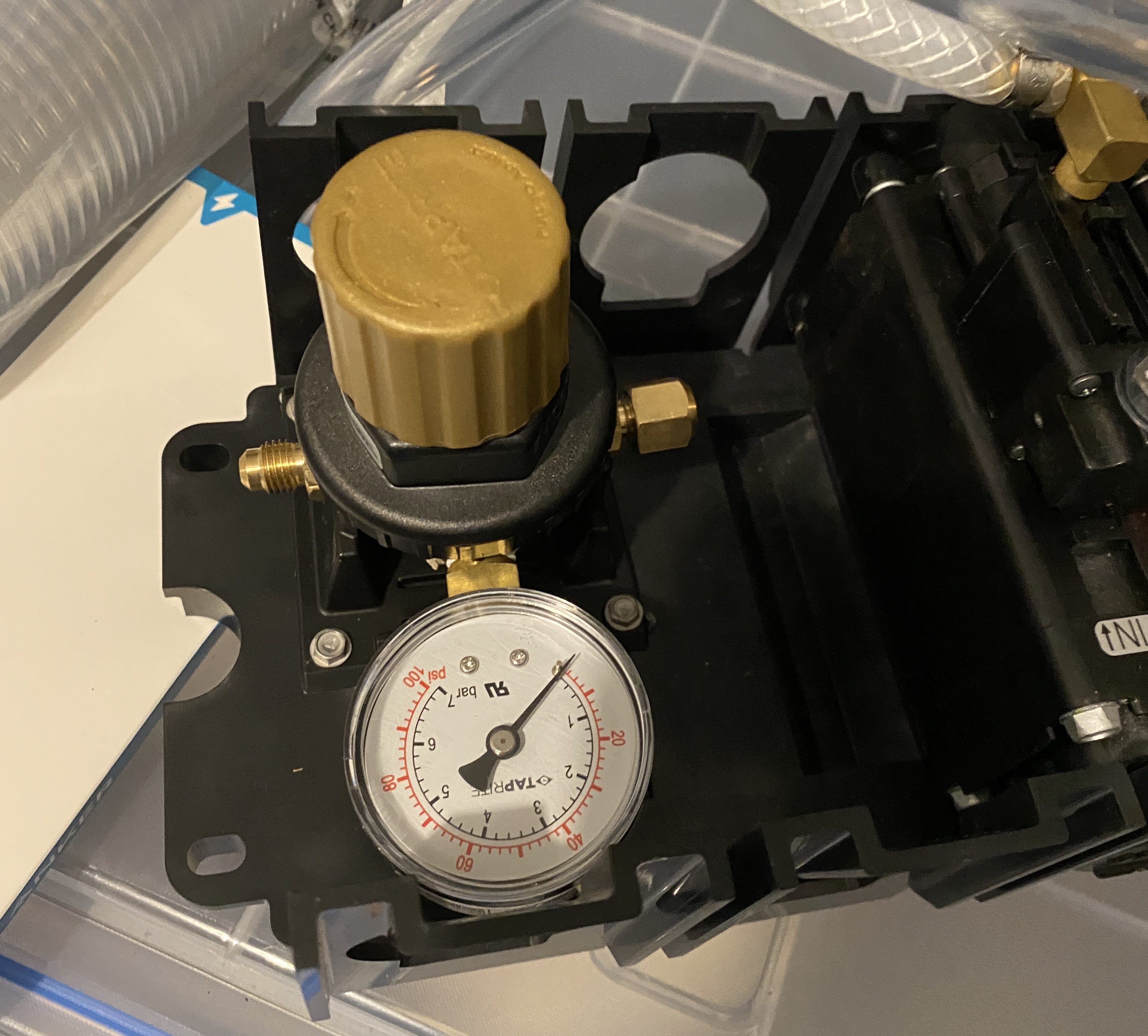

I purchased a pump kit that came with a CO2 regulator. I have a 20LB CO2 tank that I just need to connect to the kit. I was wondering what would be my best route to take to connect the two. Ideally would think I'd just need a threaded female input with a male output that I could connect my vinyl tubes with but just haven't come across a device as of yet. Attached below is the pump kit with the regulator.