RickyBeers

Well-Known Member

- Joined

- Jun 10, 2021

- Messages

- 136

- Reaction score

- 42

Hi all, new here. I had my first all grain brew yesterday on the grainfather and also decided to try pressurized fermentation, along with a Tilt. Big jump from extract brewing...

Recipe:

Relatively standard wheat beer, although I don't know a lot to be honest.

Pale Malt (2-row) 5.75lb

Wheat malt - white 5lb

Caramel malt - 20L .5lb

1oz Hersbrucker 60 min boil

1oz Czech Saaz 20 min boil

1oz Czech Saaz 10 min boil

Yeast - decided to try the Omega Lutra Kveik OYO-071 for a higher temp fermentation. I have heard this is a faux lager yeast, I have also heard that wheat and lager aren't a great combo...

Mash water 4.57 USG

Sparge water 3.18 USG

Mash at 154f 75 min

Mash out 170f 10 min

Transferred this to my sanitized corny keg after setting the spunding valve to 10 psi.

Pitched yeast, added Tilt. Also added 2 drops of five star defoamer, it suggested 1 drop per 5 gallon batch but everything I read online said to use more.

I had thought I could minimize head space, so I left maybe 2 inches. I also have a floating dip tube, if that matters to include that information.

Half way through a particularly horrible game of Warzone, I heard hissing and gurgling, and looked back to see a puddle on the floor.

Here is the thing, I thought it was odd the videos and instructions I read didn't suggest putting an 8mm tube on the spunding valve into an a vessel of water or something, but I just thought that the pressure would keep the activity in head space of the keg from over flowing through the spunding valve. Also, the yeast went nuts, so maybe it was just a incredibly active batch?

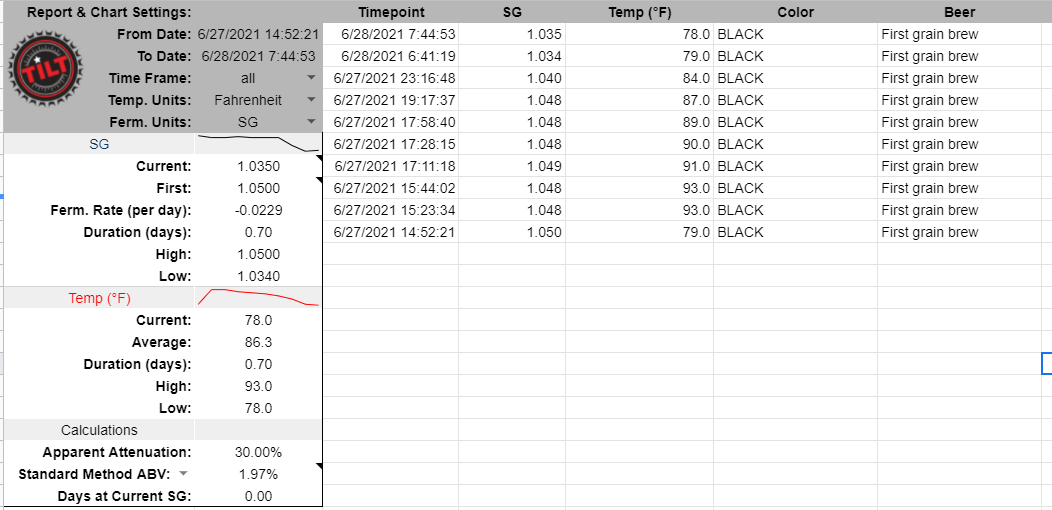

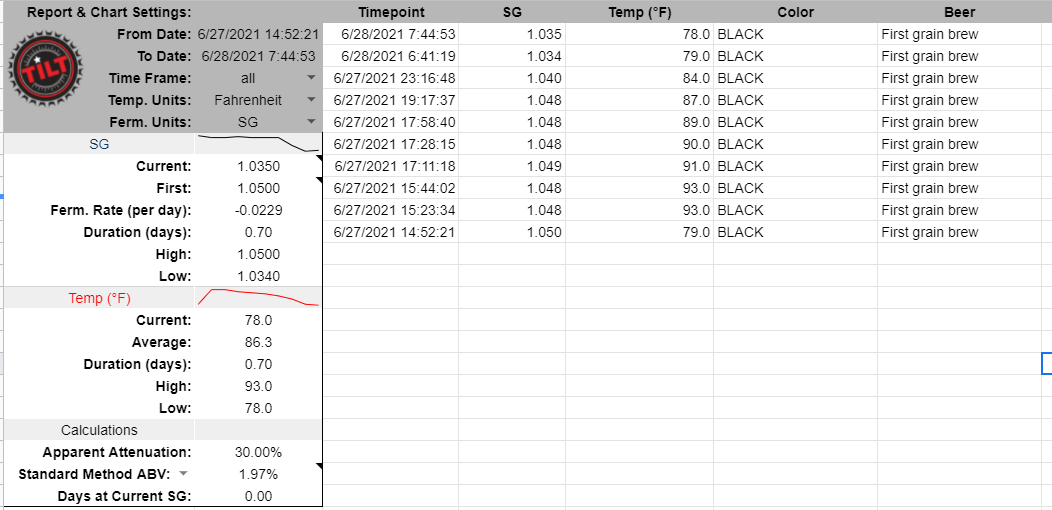

You can see below what my activity is showing in about 12 hours, a bit funky I'm guessing because of the pressure aspect with the Tilt.

I guess my question is, do I need to worry about my beer being ruined from having so much foam, liquid, and (Krausen? if that's the right word?) that came through the spunding valve and ultimately on my floor and a bucket? ALSO, for the future, how do I stop this?

Recipe:

Relatively standard wheat beer, although I don't know a lot to be honest.

Pale Malt (2-row) 5.75lb

Wheat malt - white 5lb

Caramel malt - 20L .5lb

1oz Hersbrucker 60 min boil

1oz Czech Saaz 20 min boil

1oz Czech Saaz 10 min boil

Yeast - decided to try the Omega Lutra Kveik OYO-071 for a higher temp fermentation. I have heard this is a faux lager yeast, I have also heard that wheat and lager aren't a great combo...

Mash water 4.57 USG

Sparge water 3.18 USG

Mash at 154f 75 min

Mash out 170f 10 min

Transferred this to my sanitized corny keg after setting the spunding valve to 10 psi.

Pitched yeast, added Tilt. Also added 2 drops of five star defoamer, it suggested 1 drop per 5 gallon batch but everything I read online said to use more.

I had thought I could minimize head space, so I left maybe 2 inches. I also have a floating dip tube, if that matters to include that information.

Half way through a particularly horrible game of Warzone, I heard hissing and gurgling, and looked back to see a puddle on the floor.

Here is the thing, I thought it was odd the videos and instructions I read didn't suggest putting an 8mm tube on the spunding valve into an a vessel of water or something, but I just thought that the pressure would keep the activity in head space of the keg from over flowing through the spunding valve. Also, the yeast went nuts, so maybe it was just a incredibly active batch?

You can see below what my activity is showing in about 12 hours, a bit funky I'm guessing because of the pressure aspect with the Tilt.

I guess my question is, do I need to worry about my beer being ruined from having so much foam, liquid, and (Krausen? if that's the right word?) that came through the spunding valve and ultimately on my floor and a bucket? ALSO, for the future, how do I stop this?