@dmtaylor, you're a Chem-E if I recall correctly. What do you make of this (the chlorophenol part of the discussion)?

Yes I am... by degree but maybe not in practice. My own 2 cents:

A lot of what

@barada83 says seems to make sense, he/she seems to know some stuff... but I still have points and questions which we can continue to discuss openly among all of us:

One thing I know for sure: Chlorine (Cl2 gas) is extremely reactive. I cannot see how the presence of any hypochlorite, a.k.a. "bleach", a.k.a. "chlorine" prior to mashing and boiling could NOT cause chlorophenols in the finished beer. This is to say I'm sure any standard chlorinated tap water (maybe not chloramine?) will definitely be a problem. If your water smells or tastes like a swimming pool prior to brewing with it, you're certain to have problems.

But what about chloramine? That is what I don't know so much about personally.

@barada83 seems to be making an argument that chloramine is so stable that it's really not causing a problem. Is it? I'll confess I don't really know off-hand, and that I'm too lazy to look it up, but he/she may be onto something, maybe. Worth some deeper review as we find the time.

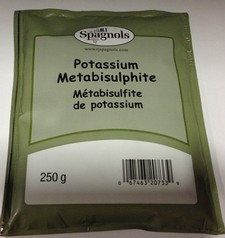

Also there is the argument that more phenol comes from the yeast itself moreso than the mash. This I believe is likely. All yeasts produce phenolic compounds, and in my own experience I know more of my witbiers and hefeweizens have had little hints of chlorophenols in my finished beers than other styles have. If I were smart, I'd start using distilled water for these styles especially, and/or maybe quit the tap water + Campden treatment for all styles at some point. I like using tap water, it's cheap and convenient, but even the usual Campden doesn't always seem to get all of it out, or at least it seems this way to me, as I'm very sensitive to chlorophenol and it drives me up the wall.

Now... Could my "chlorophenol" be some other kind of phenolic compound, not really chlorophenol? On this I have my doubts. I think we know the smell and taste of Band-Aids or Chloroseptic when we sense it. It is what it is. Get that damned hypochlorite out of your brew, via Campden or boiling or both, or better yet, use RO or distilled. It's an annoying distraction and painful to dump a batch where you find a little too much chlorophenol in the finished product, what a waste. It ain't worth the risk. I feel myself talking myself out of using tap water (my municipality uses hypochlorite) anymore. But gosh... it's just that much cheaper!

But chloramine...... is it safe to brew with? Um, I really don't know. And I don't know anyplace around here in 'Sconsin that uses it, so I have no personal experience with brews made with it.

So there's my initial thoughts. Thanks for the shout VikeMan. Cheers all.