I've spent a good part of the last 2 day's trying to figure out what fittings I will need for my keezer design. I've done my share of home improvement/repair plumbing jobs around the house and often came away frustrated with all the different options used to connect things together to move a fluid. Lets start a movement to standardize plumbing so we can spend more time brewing

OK, now that I'm done with the blab, let me share what I've learned. I'm going to keep this very detailed and hopefully simple. A lot of you already know this stuff but for those just getting started in kegging, read on. I used italics for the basic info for those who already know this stuff.

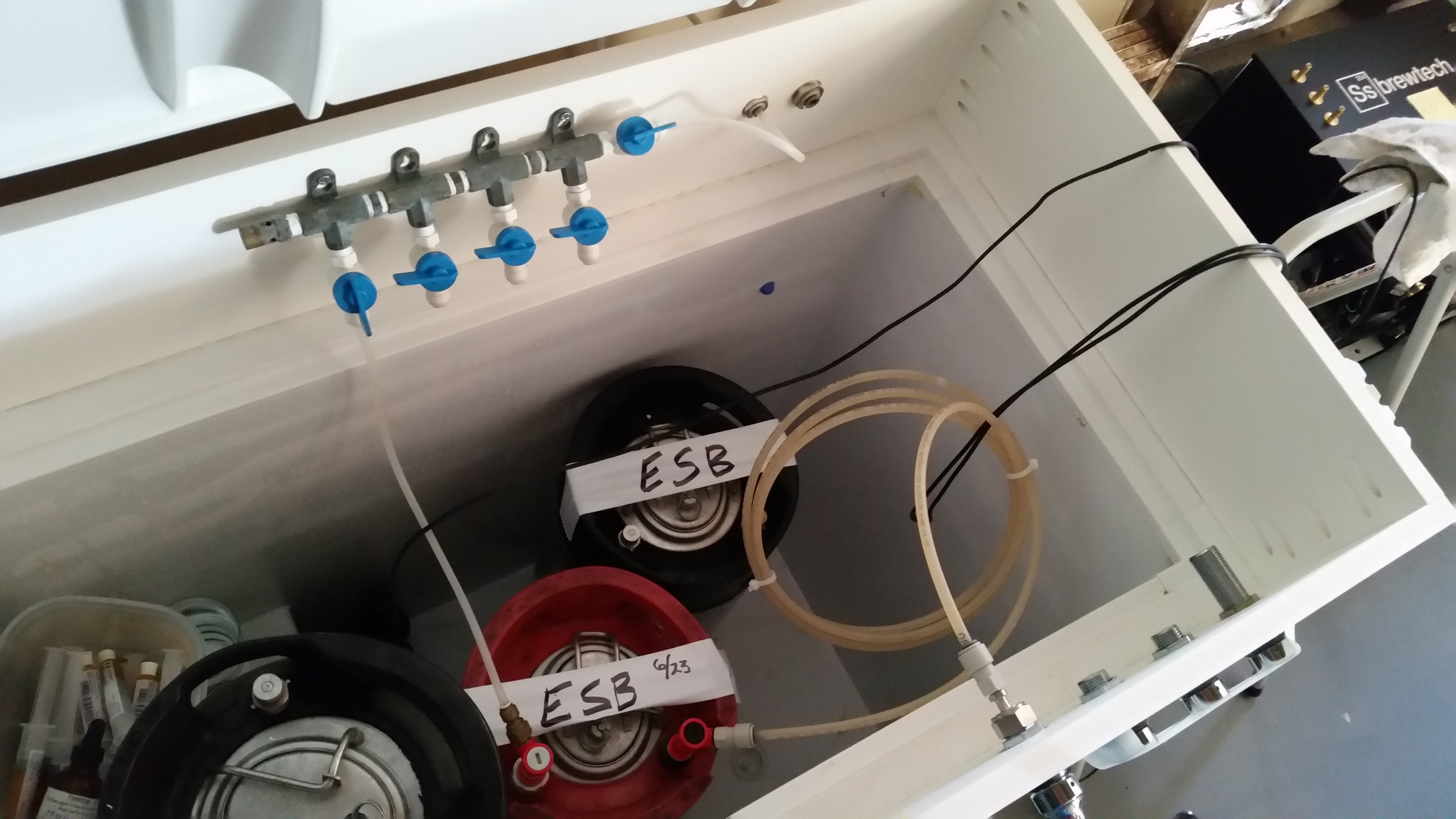

Lets start with my goal. I wanted a standardized way to run all my gas lines and beer lines to make cleaning and transporting simple. I'm planning on having 4 taps (3 corny's and 1 or 2 commerial Sanke D's). I'm running one 5lb bottle of CO2 into a double regulator. One regulator will supply a 3 way manifold, the other one is available for whatever..

Just in case you don't know, corny's are the small coke and pepsi kegs, holding 5 gallons. They both have 2 posts but use different style fittings, of course. One post allows CO2 to come in, the other is for beer out. Coke has pin style quick disconnects, 2 pins for gas in connection, 3 for beer out(beer has more letters than gas). Pepsi uses ball locks. They both have a removable oval lid with a large o-ring that opens in, allowing for easy cleaning and filling. Commercial kegs (Sanke) only have one connection in the center. The hardware that connects to the keg is called a coupler. It also has 2 attached lines, CO2 in and beer out. The important part of all of this in regards to plumbing your keezer is to know which hardware requires which fittings.

Lets start at the CO2 bottle/regulator. I have 2 ports coming out of my regulator, one will feed a 3 way manifold and the other will be for future use, but still run into the keezer. The manifold has 5/16" barb fittings and the regulator has 1/4"mfl. Time for some italics.

You'll find many different fittings/threads used in draft systems. If there is a standard, I would say most fittings are 5/16" or 1/4" barb. If you're looking to change to quick disconnects, you'll need to get familiar with a bunch of fittings, thread types, and confusing nomenclature. Fitting basics. First we need to connect hose/tubing to hardware. The side of the fitting that connects to the hardware is usually one of two types, male/female flare(mfl/ffl) or national pipe thread(npt). The other side needs to connect to the hose, usually by a barb. (BTW, I have a bad habit of interchanging line, tube and hose. all the same. sorry) The dreaded barb is the reason I've spent all this time trying to figure out how to rid my life of them. They're a royal pain in the arse. A better option is an awesome invention (John Guest is one manufacturer) that requires a simple push of the tube into the fitting and you're done. To remove, simply press the collar in the opposite direction and pull the tube out.

The best resource I found for determining which John Guest fitting to order was their on line catalog (2012). Here's the link http://www.automation-dfw.com/pdf_pneu/johnguest-catalog2012.pdf

I chose to go with their inch acetal fittings, starting on pg 8 (pdf pg number). I decided to order these fittings on line from freshwatersystems. I also chose to use 1/4" OD tube for all gas lines other than the one feeding my triple manifold. I thought I may as well leave that one with my 9/16" OD tube I am currently using since it's feeding three kegs and I don't foresee a reason to disconnect. I bought the 1/4" tubing from McMaster-Carr, http://www.mcmaster.com/#catalog/119/136/=vzzpcp. Part number 5648K69 for clear/tinted and 5648K25 for opaque. Sold in 25', 50', and 100' lengths. I got 25' of 4 different colors to identify which gas line is feeding which keg. As a side note, the tubing arrived next day. Thanks MC. This is a good time to give huge thanks to Thadius for his posts regarding his keezer. His post was a big help. Here's the link to that post. https://www.homebrewtalk.com/f35/its-finally-done-my-10-tap-keezer-449284/

Back to our CO2 regulator fitting(s). If you have the 1/4"mfl (male flare) port coming out of your regulator, you'll need part U0420476. This is not a John Guest fitting. I had to call customer service to find it. Type it into the website to see what it looks like.

You may have a barb coming out of your regulator, instead of an mfl. I would remove this barb and screw in an mfl fitting. If it's 1/4" nptf going into the reg, order part PI010822S. That'll give you 1/4" tube exit. If it's 1/4" female flare, you'll need PI0108F4S. Again, giving you 1/4" tube exit. I've read some regs use left hand threads. Uggg, not going there. Buy a reg with 1/4" mfl and be happy.

As I mentioned above, I decided to keep my large 9/16" gas line connected to my 3 way manifold so I didn't need a fitting into the manifold. Coming out of the manifold was a problem. Most manifold's have check valves built into the ball valve to prevent beer from back flowing into your gas line. Mine has these check valves but they're built into the barb fitting that exits the ball valve. I was hoping to simply remove the barb fitting and replace with an mfl until I remembered the check valve. These things come as one piece, ball valve/check valve/exit fitting. Next time, buy a manifold with mfl's on the exit if you plan on using quick disconnect fittings! I chose to order 3 new ball/check valves with 1/4" mfl fittings and toss the junky valves with barbs. My manifold just got more expensive. Oh well, it's for a good cause. Get part PI450822S, or 3 in my case.

Getting there. We now have 1/4" od tube going to the keg. You have 2 options when ordering your keg disconnects, threaded or barbed. Don't go barb. The thread is 1/4" mfl. Nice. Get part PI450822S. Gas line done to corny keg!!!

Now if you want to run the gas line to a commercial Sanke D, you'll probably find the threads to be the same as a beer shank, 7/8"-14. Lets keep the madness going. You'll probably see 5/8 BSP instead of the 7/8-14. BSP is a British standard. How did we get them in the mix, I have no clue. Anyway, 7/8-14 is the same as 5/8 bsp. Sooo, we need a fitting with a female end to fit 5/8 bsp and the other end 1/4" od tube. Couldn't find it so I had to get 2 fittings. The first one, PI451015FS, will get us from the 5/8 bsp to 5/16" tube. Now we need to step down to 1/4" tube, so get PI061008S. Shove the1/4" tube into the fitting and your gas is done.

Time for the beer lines.

Plenty of discussions out there on what line to use. I chose 3/16" id, 5/16" od. Remember, you need to use od with this type of quick disconnect.

Lets start at the kegs. Corny's first, of course. Same fitting as keg gas disconnect, PI450822S. 1/4"mfl to 1/4" od tube.

Now our craft brew is leaving the keg and going into the beer shank. From above we know what threads are on the shank but now our line is larger, 5/16" instead of 1/4". Well, we already used that fitting on the gas but had to reduce it. Get another one without buying the reducer, PI451015FS.

Beer is almost there. I'm getting thirsty. It's now going through the shank and needs to get into my glass. Oh yeah, how about a coupler (aka tap). Choose your favorite and enjoy.

Wait, what about a commercial Sanke D beer out fitting. Just so happens it has the same threads as the gas in, good ole 5/8 bsp. Finally, something easy. Just remember the beer line is larger (mine anyway) so no need for the reducer. PI451015FS

The rest is the same as above.

I hope I didn't babble on for too long but I really spent a ton of time figuring all of this out. I probably had 25 windows open trying to decipher all of the different types of threads/fittings as well as a place to purchase.

Hope this helps.

Someday I plan on uploading pictures....

OK, now that I'm done with the blab, let me share what I've learned. I'm going to keep this very detailed and hopefully simple. A lot of you already know this stuff but for those just getting started in kegging, read on. I used italics for the basic info for those who already know this stuff.

Lets start with my goal. I wanted a standardized way to run all my gas lines and beer lines to make cleaning and transporting simple. I'm planning on having 4 taps (3 corny's and 1 or 2 commerial Sanke D's). I'm running one 5lb bottle of CO2 into a double regulator. One regulator will supply a 3 way manifold, the other one is available for whatever..

Just in case you don't know, corny's are the small coke and pepsi kegs, holding 5 gallons. They both have 2 posts but use different style fittings, of course. One post allows CO2 to come in, the other is for beer out. Coke has pin style quick disconnects, 2 pins for gas in connection, 3 for beer out(beer has more letters than gas). Pepsi uses ball locks. They both have a removable oval lid with a large o-ring that opens in, allowing for easy cleaning and filling. Commercial kegs (Sanke) only have one connection in the center. The hardware that connects to the keg is called a coupler. It also has 2 attached lines, CO2 in and beer out. The important part of all of this in regards to plumbing your keezer is to know which hardware requires which fittings.

Lets start at the CO2 bottle/regulator. I have 2 ports coming out of my regulator, one will feed a 3 way manifold and the other will be for future use, but still run into the keezer. The manifold has 5/16" barb fittings and the regulator has 1/4"mfl. Time for some italics.

You'll find many different fittings/threads used in draft systems. If there is a standard, I would say most fittings are 5/16" or 1/4" barb. If you're looking to change to quick disconnects, you'll need to get familiar with a bunch of fittings, thread types, and confusing nomenclature. Fitting basics. First we need to connect hose/tubing to hardware. The side of the fitting that connects to the hardware is usually one of two types, male/female flare(mfl/ffl) or national pipe thread(npt). The other side needs to connect to the hose, usually by a barb. (BTW, I have a bad habit of interchanging line, tube and hose. all the same. sorry) The dreaded barb is the reason I've spent all this time trying to figure out how to rid my life of them. They're a royal pain in the arse. A better option is an awesome invention (John Guest is one manufacturer) that requires a simple push of the tube into the fitting and you're done. To remove, simply press the collar in the opposite direction and pull the tube out.

The best resource I found for determining which John Guest fitting to order was their on line catalog (2012). Here's the link http://www.automation-dfw.com/pdf_pneu/johnguest-catalog2012.pdf

I chose to go with their inch acetal fittings, starting on pg 8 (pdf pg number). I decided to order these fittings on line from freshwatersystems. I also chose to use 1/4" OD tube for all gas lines other than the one feeding my triple manifold. I thought I may as well leave that one with my 9/16" OD tube I am currently using since it's feeding three kegs and I don't foresee a reason to disconnect. I bought the 1/4" tubing from McMaster-Carr, http://www.mcmaster.com/#catalog/119/136/=vzzpcp. Part number 5648K69 for clear/tinted and 5648K25 for opaque. Sold in 25', 50', and 100' lengths. I got 25' of 4 different colors to identify which gas line is feeding which keg. As a side note, the tubing arrived next day. Thanks MC. This is a good time to give huge thanks to Thadius for his posts regarding his keezer. His post was a big help. Here's the link to that post. https://www.homebrewtalk.com/f35/its-finally-done-my-10-tap-keezer-449284/

Back to our CO2 regulator fitting(s). If you have the 1/4"mfl (male flare) port coming out of your regulator, you'll need part U0420476. This is not a John Guest fitting. I had to call customer service to find it. Type it into the website to see what it looks like.

You may have a barb coming out of your regulator, instead of an mfl. I would remove this barb and screw in an mfl fitting. If it's 1/4" nptf going into the reg, order part PI010822S. That'll give you 1/4" tube exit. If it's 1/4" female flare, you'll need PI0108F4S. Again, giving you 1/4" tube exit. I've read some regs use left hand threads. Uggg, not going there. Buy a reg with 1/4" mfl and be happy.

As I mentioned above, I decided to keep my large 9/16" gas line connected to my 3 way manifold so I didn't need a fitting into the manifold. Coming out of the manifold was a problem. Most manifold's have check valves built into the ball valve to prevent beer from back flowing into your gas line. Mine has these check valves but they're built into the barb fitting that exits the ball valve. I was hoping to simply remove the barb fitting and replace with an mfl until I remembered the check valve. These things come as one piece, ball valve/check valve/exit fitting. Next time, buy a manifold with mfl's on the exit if you plan on using quick disconnect fittings! I chose to order 3 new ball/check valves with 1/4" mfl fittings and toss the junky valves with barbs. My manifold just got more expensive. Oh well, it's for a good cause. Get part PI450822S, or 3 in my case.

Getting there. We now have 1/4" od tube going to the keg. You have 2 options when ordering your keg disconnects, threaded or barbed. Don't go barb. The thread is 1/4" mfl. Nice. Get part PI450822S. Gas line done to corny keg!!!

Now if you want to run the gas line to a commercial Sanke D, you'll probably find the threads to be the same as a beer shank, 7/8"-14. Lets keep the madness going. You'll probably see 5/8 BSP instead of the 7/8-14. BSP is a British standard. How did we get them in the mix, I have no clue. Anyway, 7/8-14 is the same as 5/8 bsp. Sooo, we need a fitting with a female end to fit 5/8 bsp and the other end 1/4" od tube. Couldn't find it so I had to get 2 fittings. The first one, PI451015FS, will get us from the 5/8 bsp to 5/16" tube. Now we need to step down to 1/4" tube, so get PI061008S. Shove the1/4" tube into the fitting and your gas is done.

Time for the beer lines.

Plenty of discussions out there on what line to use. I chose 3/16" id, 5/16" od. Remember, you need to use od with this type of quick disconnect.

Lets start at the kegs. Corny's first, of course. Same fitting as keg gas disconnect, PI450822S. 1/4"mfl to 1/4" od tube.

Now our craft brew is leaving the keg and going into the beer shank. From above we know what threads are on the shank but now our line is larger, 5/16" instead of 1/4". Well, we already used that fitting on the gas but had to reduce it. Get another one without buying the reducer, PI451015FS.

Beer is almost there. I'm getting thirsty. It's now going through the shank and needs to get into my glass. Oh yeah, how about a coupler (aka tap). Choose your favorite and enjoy.

Wait, what about a commercial Sanke D beer out fitting. Just so happens it has the same threads as the gas in, good ole 5/8 bsp. Finally, something easy. Just remember the beer line is larger (mine anyway) so no need for the reducer. PI451015FS

The rest is the same as above.

I hope I didn't babble on for too long but I really spent a ton of time figuring all of this out. I probably had 25 windows open trying to decipher all of the different types of threads/fittings as well as a place to purchase.

Hope this helps.

Someday I plan on uploading pictures....