p40whk

Well-Known Member

- Joined

- Sep 23, 2013

- Messages

- 131

- Reaction score

- 11

For those of you that are using a plate chiller, does the temps at the exit of the chiller come close to pitching temps ore do you recirculate the wort through your brew kettle until the temps stabilize to pitching temps then pump to your fermenter?

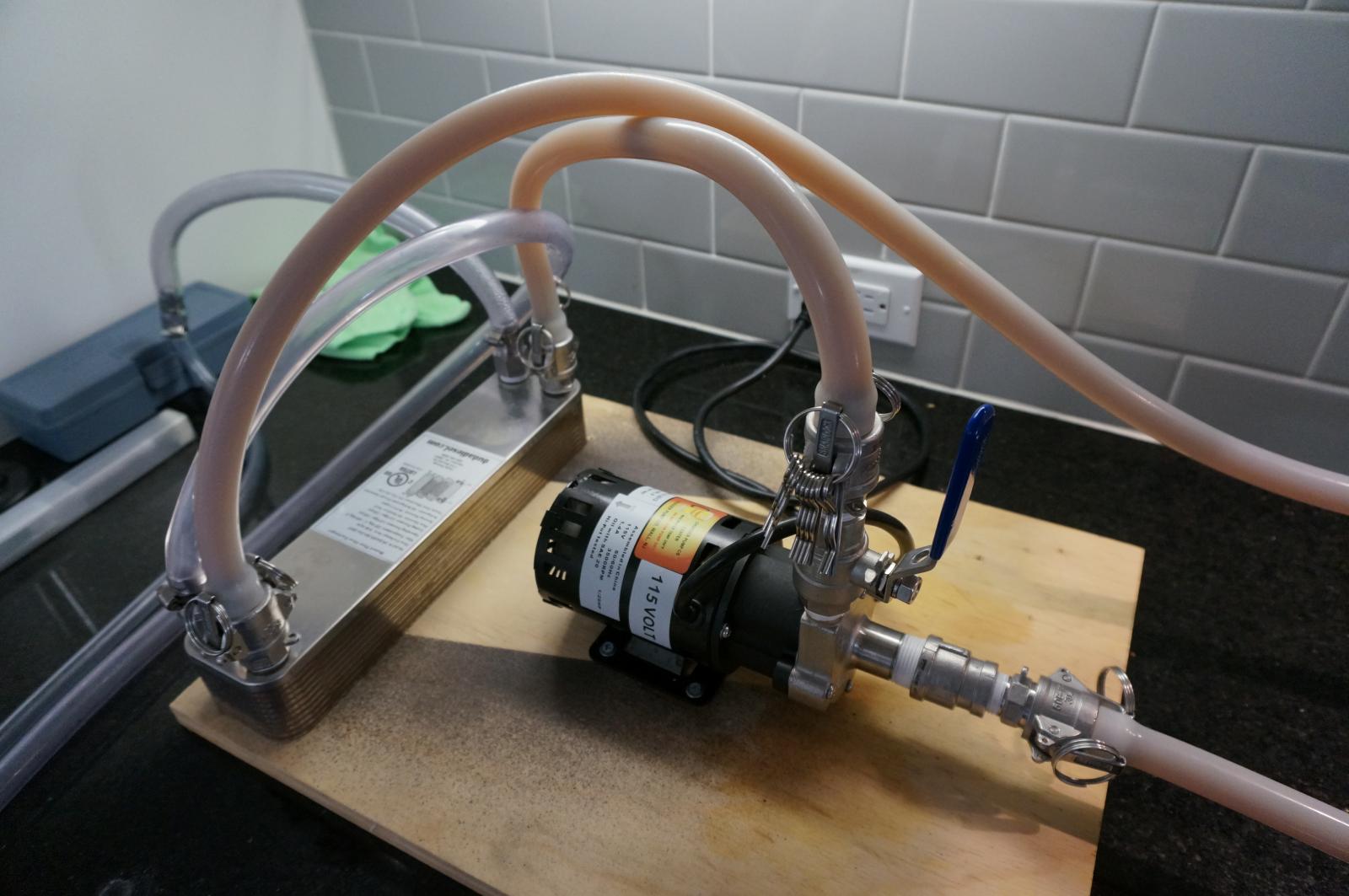

Edit: I purchased a B3-36A 20 plate chiller from Duda Diesel

Edit: I purchased a B3-36A 20 plate chiller from Duda Diesel