Hey guys,

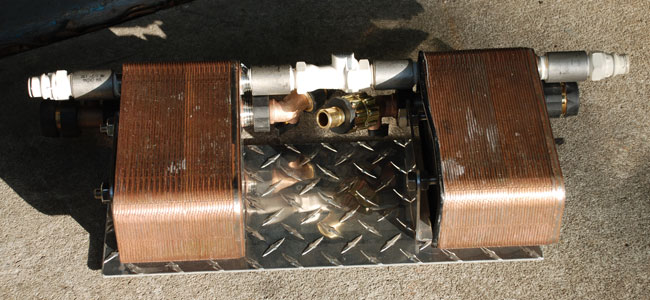

Got this 50 plate chiller from Keg Cowboy 3-4 yrs ago. Worked Ok when I got it. Took like 8 min to chill 5.5 gal from boil to 70. Has been getting worse and worse it seems over time. Today took 25 min at a trickle from boil to 70. Flow is still good so I dont think it's clogged. Oriented horizontally. Did a search and couldnt find anything. Any help would be appreciated. Thnx

Got this 50 plate chiller from Keg Cowboy 3-4 yrs ago. Worked Ok when I got it. Took like 8 min to chill 5.5 gal from boil to 70. Has been getting worse and worse it seems over time. Today took 25 min at a trickle from boil to 70. Flow is still good so I dont think it's clogged. Oriented horizontally. Did a search and couldnt find anything. Any help would be appreciated. Thnx