nspaldi0

Well-Known Member

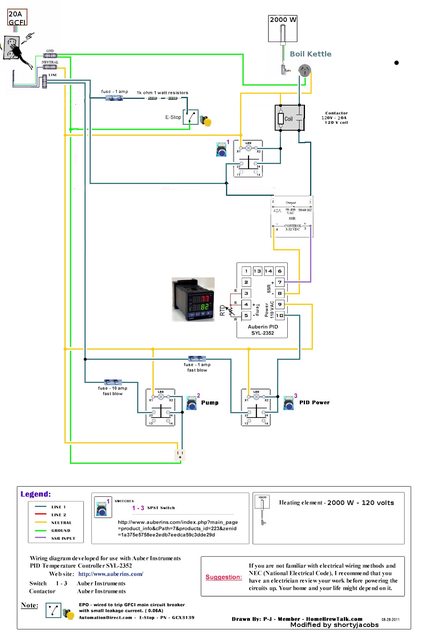

Like many here, I've been drooling over the electric systems and want to go route. I am in the process of planning a system exactly like the system at this link https://www.homebrewtalk.com/f51/brewkart-ditches-countertop-brutus-205427/index2.html. Does anyone have a wiring diagram for this? I won't be wiring this because that is a skill I don't have but do have an electrical engineering friend who is happy to wire it for me but I'd like to give him a diagram to go off of.

PJ,

Do you have a diagram already for this?

Thanks for the help! Winter is here and this is my latest project. Still need to finish the keezer top! But it never hurts to have multiple projects!

Nick

PJ,

Do you have a diagram already for this?

Thanks for the help! Winter is here and this is my latest project. Still need to finish the keezer top! But it never hurts to have multiple projects!

Nick