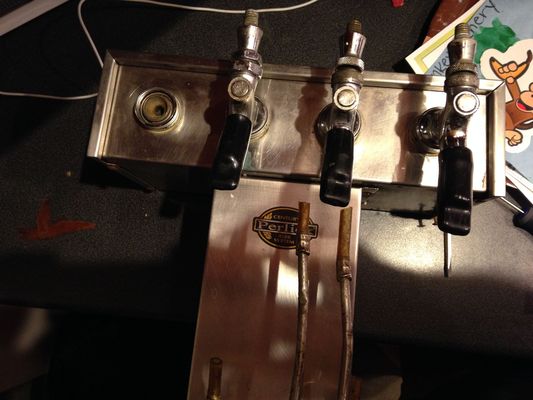

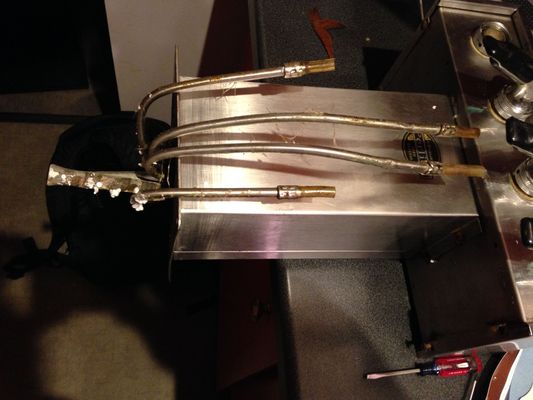

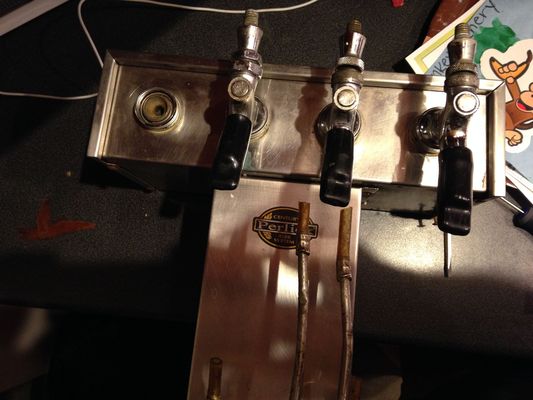

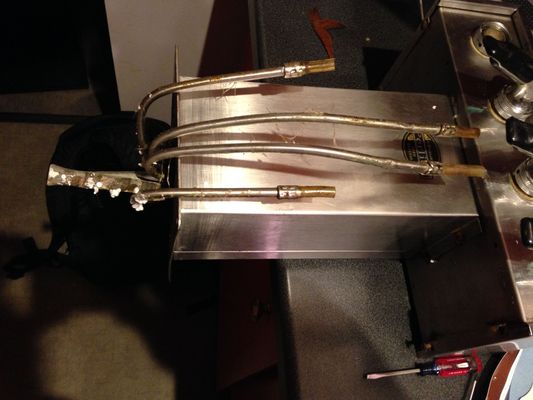

Just bought this off Ebay. It has 4 taps, glycol cooling and even came with a Guinness tap. In the ad, it showed all the copper/stainless lines as uncut and straight. When they shipped it, the bastard cut the copper lines with wire cutters and tried to cut one of the stainless lines, only damaging it. Then they bent the stainless lines, thankfully not crimping them.

This will be mounted on top of my keezer, so the trimmed lines aren't a dealbreaker. I do, however, need to make the lines water tight. What's the acceptable method for doing this? Bubble flare tool? Simple hose clamps? Replace the metal lines somehow?

I can't find any internal diagrams of this thing either, when I search "Perlick Repair", all I get is for sale stuff. Anybody have a lead on anything?

This will be mounted on top of my keezer, so the trimmed lines aren't a dealbreaker. I do, however, need to make the lines water tight. What's the acceptable method for doing this? Bubble flare tool? Simple hose clamps? Replace the metal lines somehow?

I can't find any internal diagrams of this thing either, when I search "Perlick Repair", all I get is for sale stuff. Anybody have a lead on anything?