BaldApe

Well-Known Member

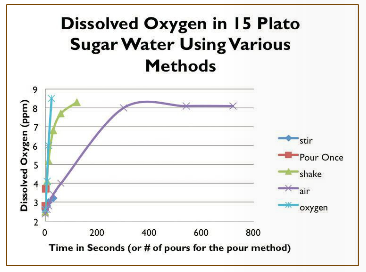

I started using a welding oxygen tank with a sintered stone, and have been getting solventy off flavors. I believe I have been adding too much oxygen.

I'm going to buy a flow meter, and I'm looking for pointers on how much oxygen should be added in the fermenter- flow rate and time.

I can do trial and error, but I'm tired of beer coming out barely drinkable.

I'm going to buy a flow meter, and I'm looking for pointers on how much oxygen should be added in the fermenter- flow rate and time.

I can do trial and error, but I'm tired of beer coming out barely drinkable.