Hello All,

so after doing many stovetop 5 gallon batches, with good response, I thought it would be a great idea to brew all the beer for my upcoming wedding. In retrospect it would most likely be easier/cheaper to buy it but where is the fun in that.

Over the past couple of months I have been planning and acquiring the hardware for the liquid process, now Id like to bounce ideas off of the experts here for the control panel and setup.

What I have is:

A 5ft SS Prep Table

~13 Gallon "Keggle" HLT with Thermometer and sight glass

~55? qt Cooler as a Mashtun

15.5 Gal Keggle BK

1 March Pump

CF Wort Chiller

All of quick disconnects

You can see the components here:

http://www.brewmunity.com/home/75-travis-cozzie/photos/photo?albumid=13#photoid=44

So my plan is to heat in the HLT, Pump to MT, Batch Sparge, Pump to BK, Cool to fermenter.

My questions are:

I can already see how I will benefit from another pump, but is it absolutely necessary? I could lift the runnings into the BK.

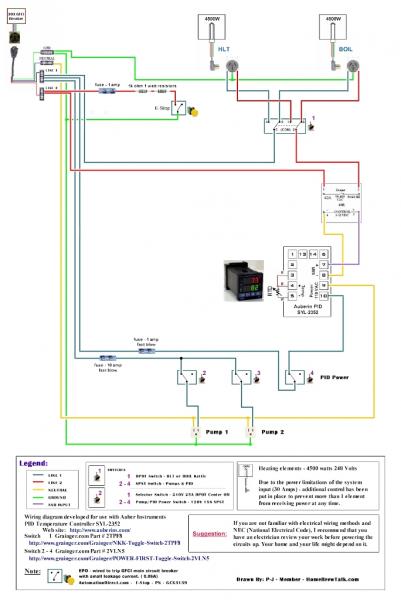

My plan was to have 2 5500W elements, one for HLT, one for BK, I would also like to control the pump, an exhaust fan and have a timer in the control box, I'm still researching but off the top of anyones head do they know a diagram that fits that bill?

My plan is to wire in a spa panel, that can be plugged into my dryer outlet. I will also have hard water lines plumbed to the table location, and an exhaust fan overhead. With the ultimate goal of having a quick disconnect for power, and water, and the ability to move the table if needed.

Lastly, being so close to the project, with a new set of eyes am I missing anything?

TIA for all your help!

Travis

so after doing many stovetop 5 gallon batches, with good response, I thought it would be a great idea to brew all the beer for my upcoming wedding. In retrospect it would most likely be easier/cheaper to buy it but where is the fun in that.

Over the past couple of months I have been planning and acquiring the hardware for the liquid process, now Id like to bounce ideas off of the experts here for the control panel and setup.

What I have is:

A 5ft SS Prep Table

~13 Gallon "Keggle" HLT with Thermometer and sight glass

~55? qt Cooler as a Mashtun

15.5 Gal Keggle BK

1 March Pump

CF Wort Chiller

All of quick disconnects

You can see the components here:

http://www.brewmunity.com/home/75-travis-cozzie/photos/photo?albumid=13#photoid=44

So my plan is to heat in the HLT, Pump to MT, Batch Sparge, Pump to BK, Cool to fermenter.

My questions are:

I can already see how I will benefit from another pump, but is it absolutely necessary? I could lift the runnings into the BK.

My plan was to have 2 5500W elements, one for HLT, one for BK, I would also like to control the pump, an exhaust fan and have a timer in the control box, I'm still researching but off the top of anyones head do they know a diagram that fits that bill?

My plan is to wire in a spa panel, that can be plugged into my dryer outlet. I will also have hard water lines plumbed to the table location, and an exhaust fan overhead. With the ultimate goal of having a quick disconnect for power, and water, and the ability to move the table if needed.

Lastly, being so close to the project, with a new set of eyes am I missing anything?

TIA for all your help!

Travis

- So a mixture of baking soda and water and a pressure washer was used to remove the gunk.

- So a mixture of baking soda and water and a pressure washer was used to remove the gunk.