Hey guys! I don't do home brewing, but I do have a question and need help with my PID controller. I got a food warmer oven that I am wiring up to do bake-on firearm and knife finishes with a product called Cerakote. Anyway...

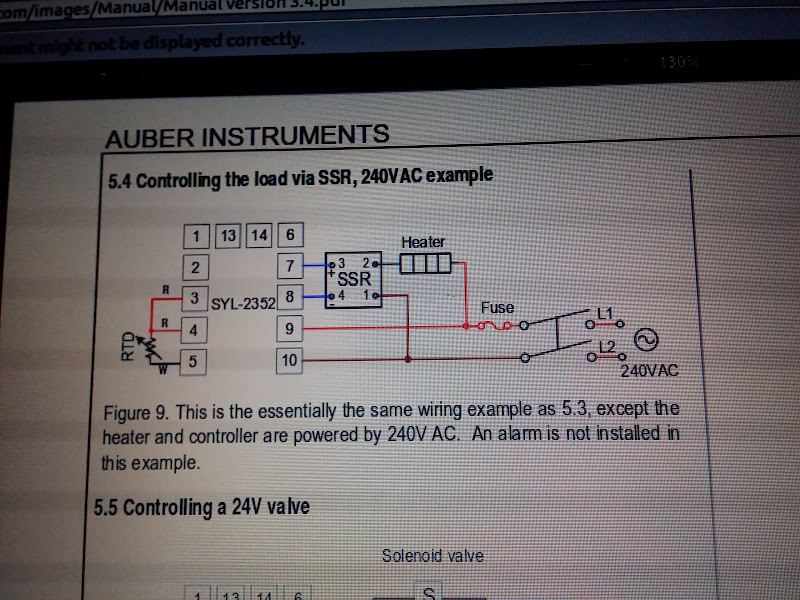

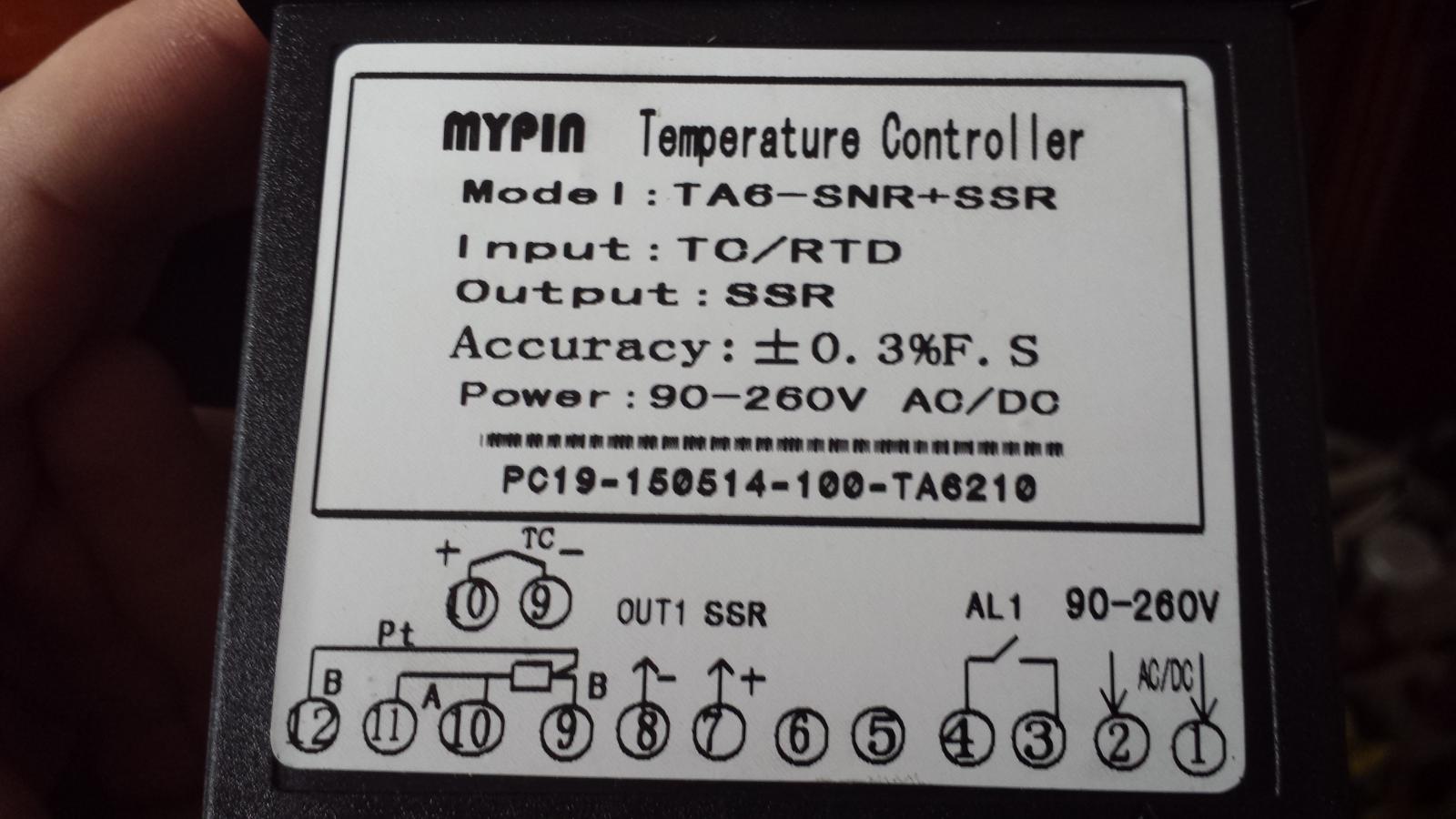

I wired everything up but I am not getting any power to my heating elements... (its a 230-240v system and everything was pre-wired, I just replaced the normal switch to turn the oven on and up with the PID controller). I am getting the full power to my PID controller, but on the output that goes to my SSR I am only getting power (about 50v) on one of the wires and not the other... did I wire wrong or is this just a setting?

note: the conduit that has both sets of the red and black wires coming out of it used to go to the old switch: the two plain colors are the hot wires, and the two with the yellow tape on them are the dead wires (which I assumed were supposed to be "connected" by the switch)

I wired everything up but I am not getting any power to my heating elements... (its a 230-240v system and everything was pre-wired, I just replaced the normal switch to turn the oven on and up with the PID controller). I am getting the full power to my PID controller, but on the output that goes to my SSR I am only getting power (about 50v) on one of the wires and not the other... did I wire wrong or is this just a setting?

note: the conduit that has both sets of the red and black wires coming out of it used to go to the old switch: the two plain colors are the hot wires, and the two with the yellow tape on them are the dead wires (which I assumed were supposed to be "connected" by the switch)