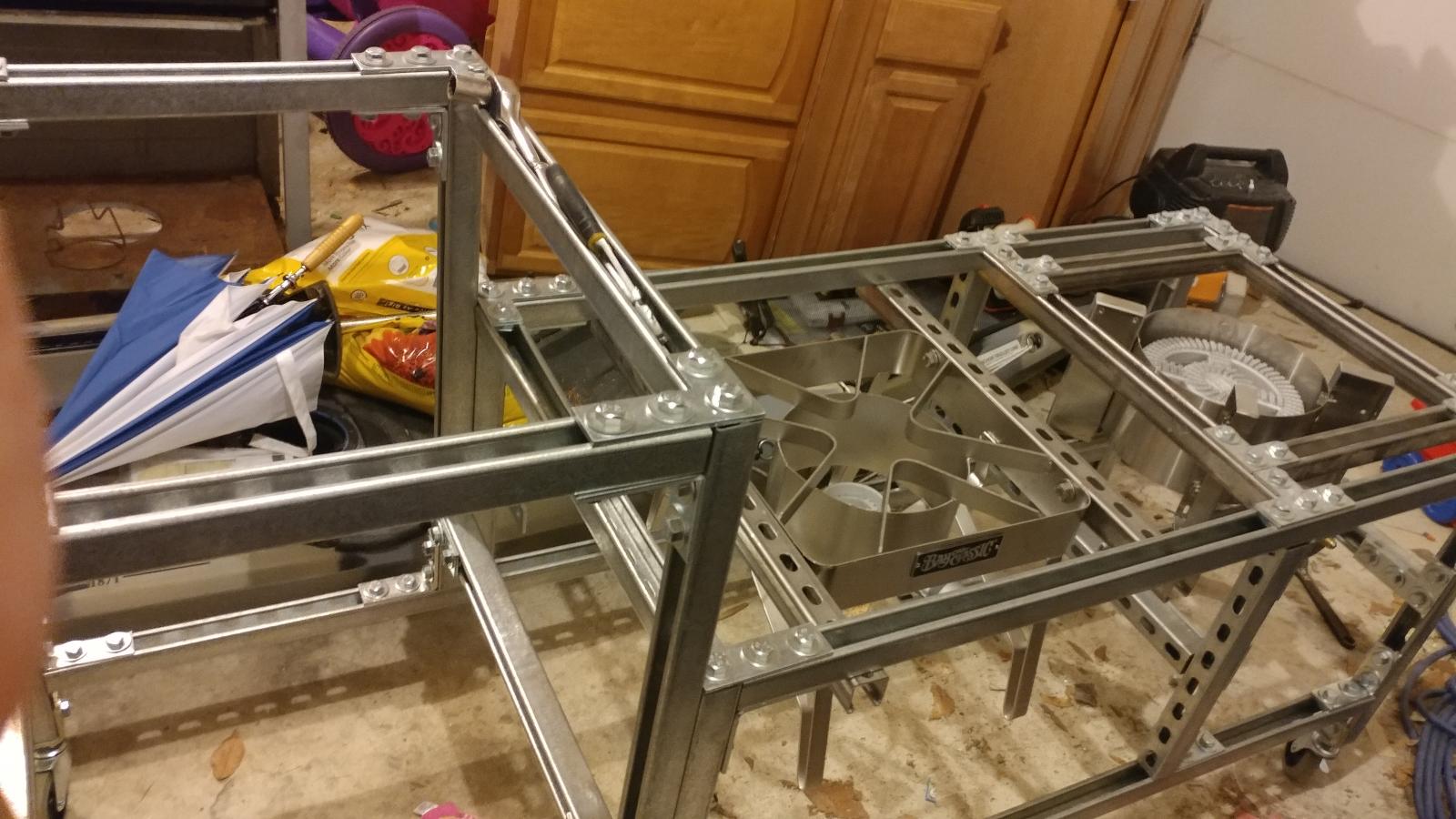

I've been working on this for a couple of months now, so I'm excited to finally be able to show it off.  Here is what everything looks like together:

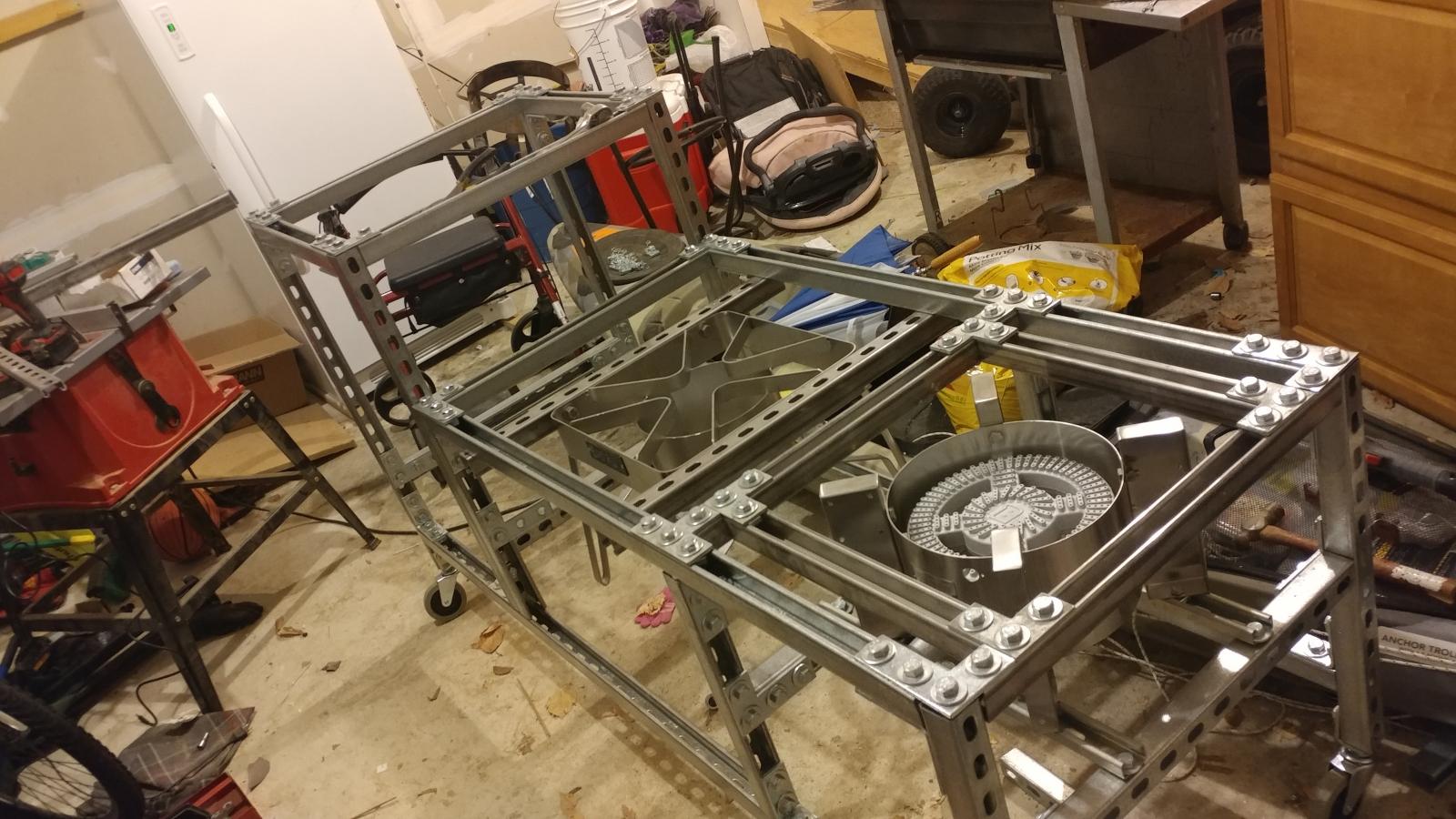

Here is what everything looks like together:

One kettle serves double duty as the HLT & BK while the other is the mash tun. Both are 15 gallon Bayou Classic kettles where I drilled a 2nd hole for the whirlpool and recirculation ports. 3-piece ball valves and camlock fittings all the way around:

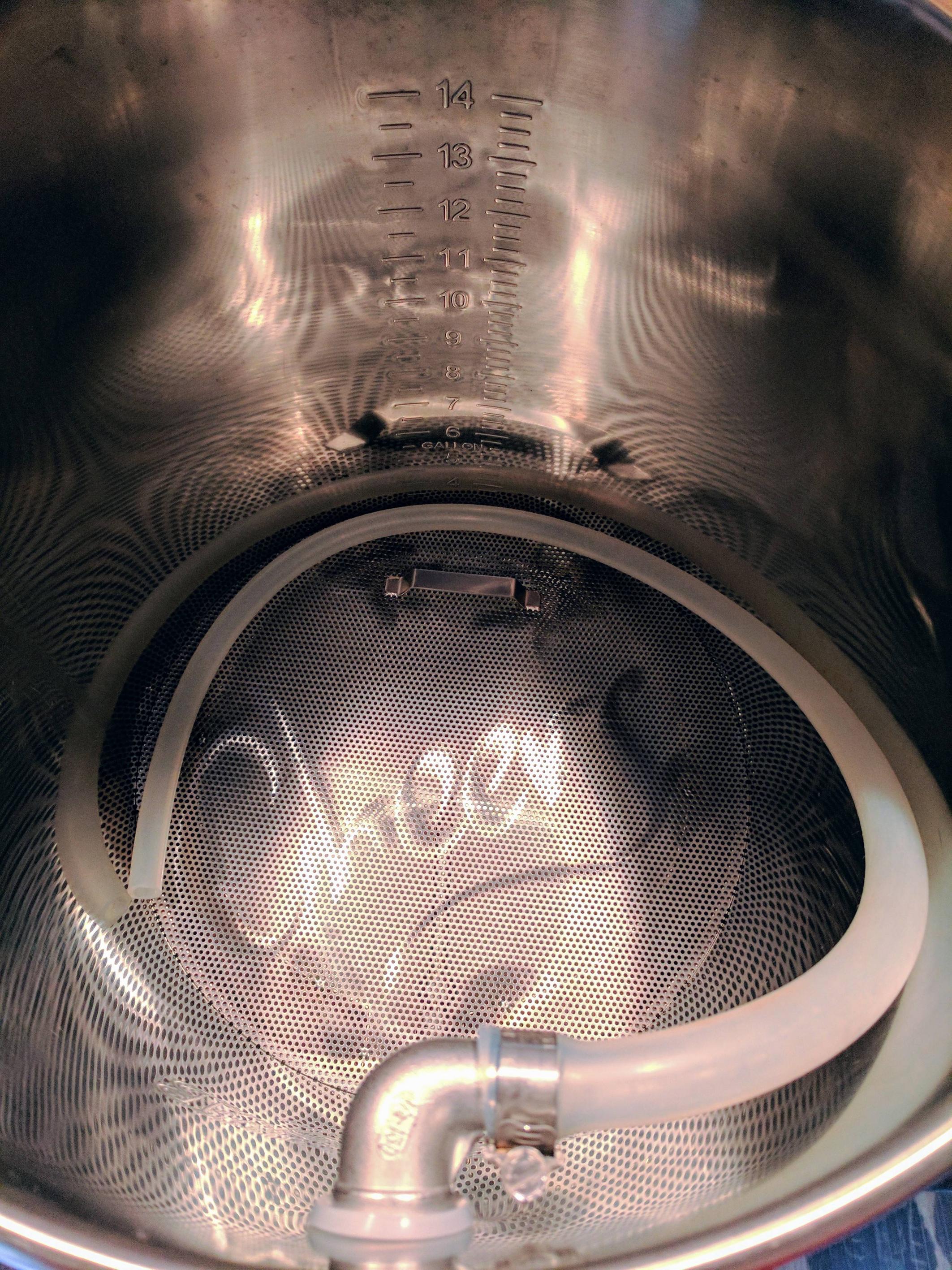

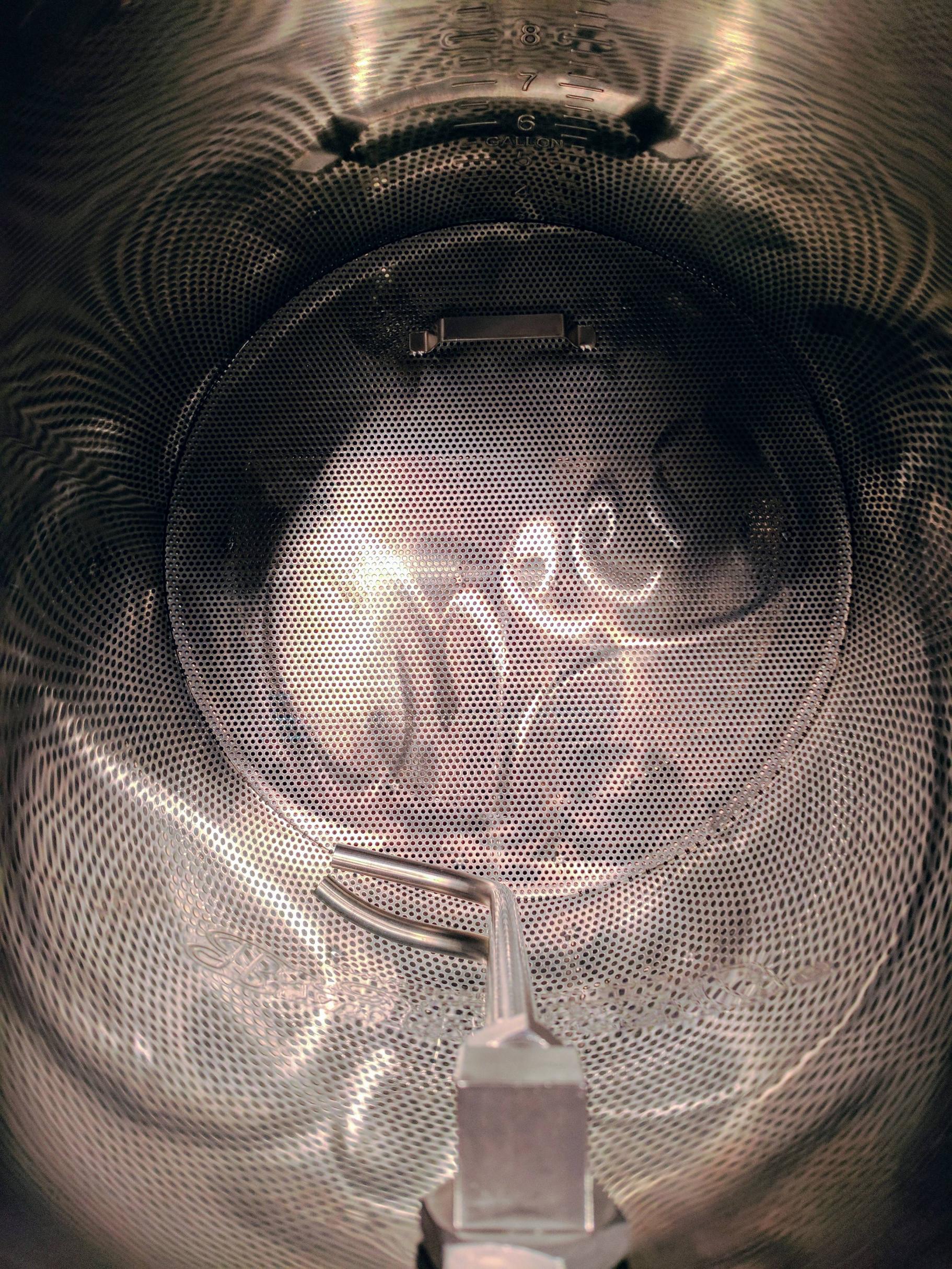

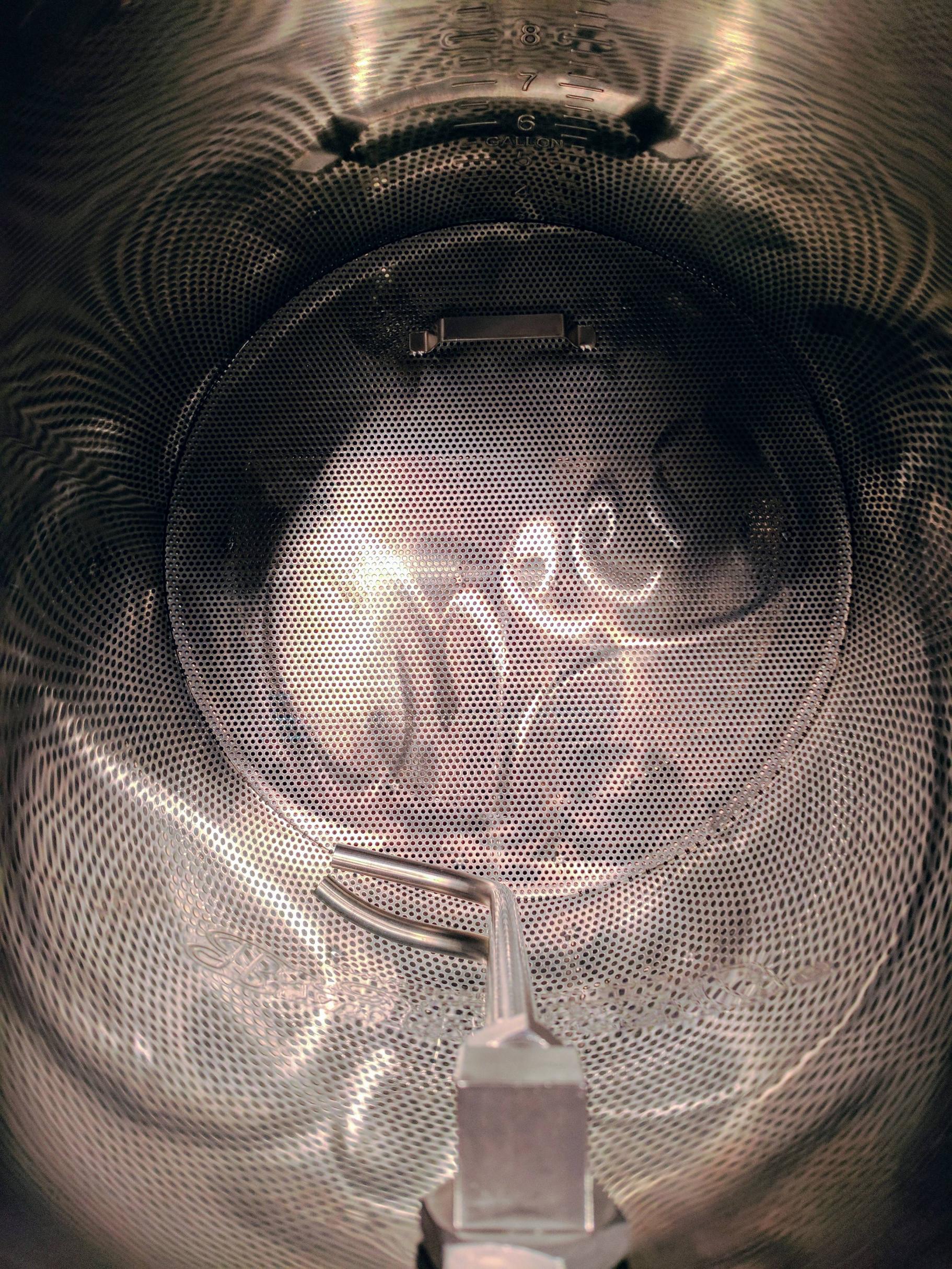

Inside of mash tun with simple recirculation setup and Norcal Brewing Solutions custom false bottom:

Mash tun false bottom removed to show the Norcal Brewing cut-to-length dip tube:

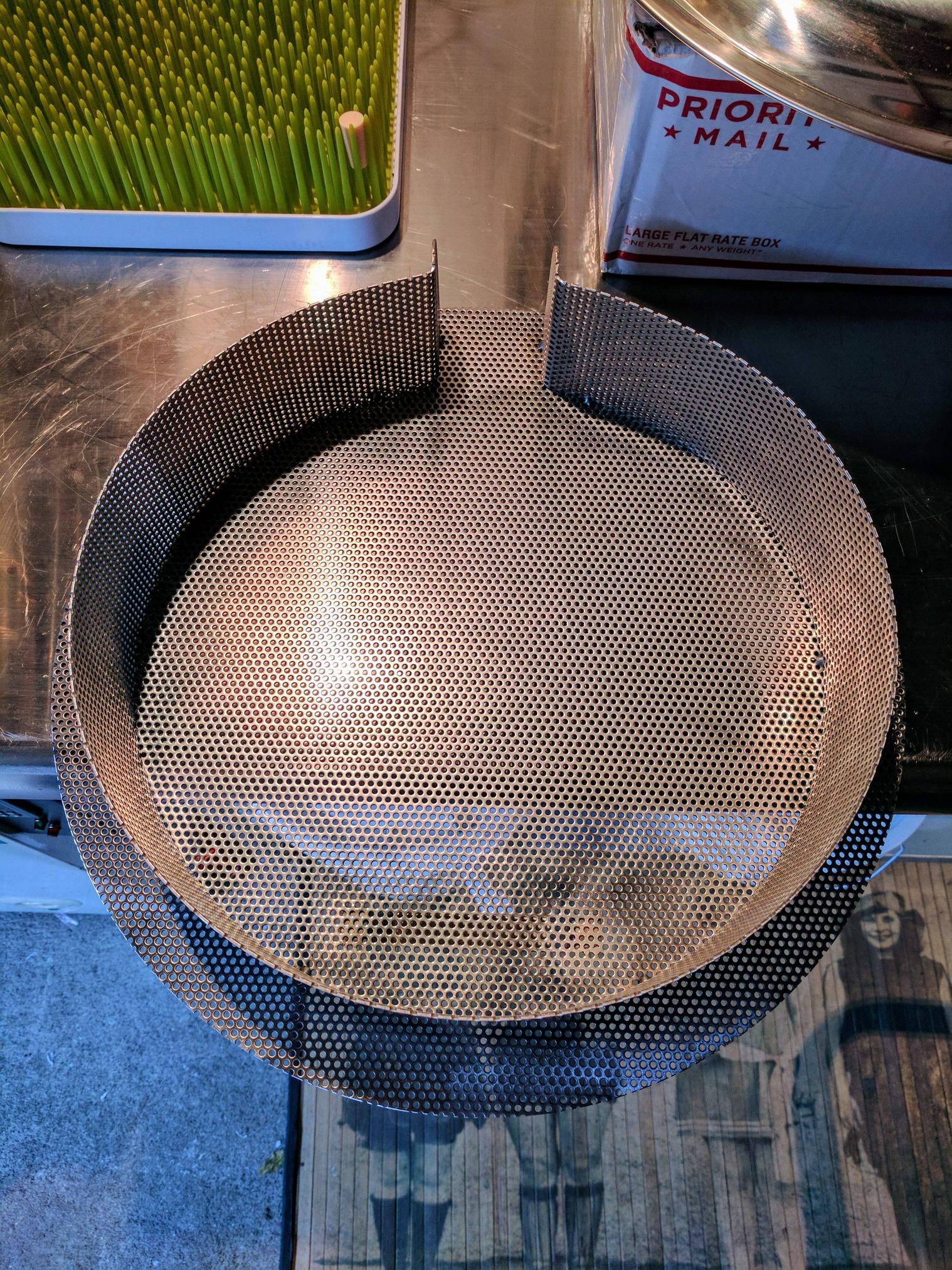

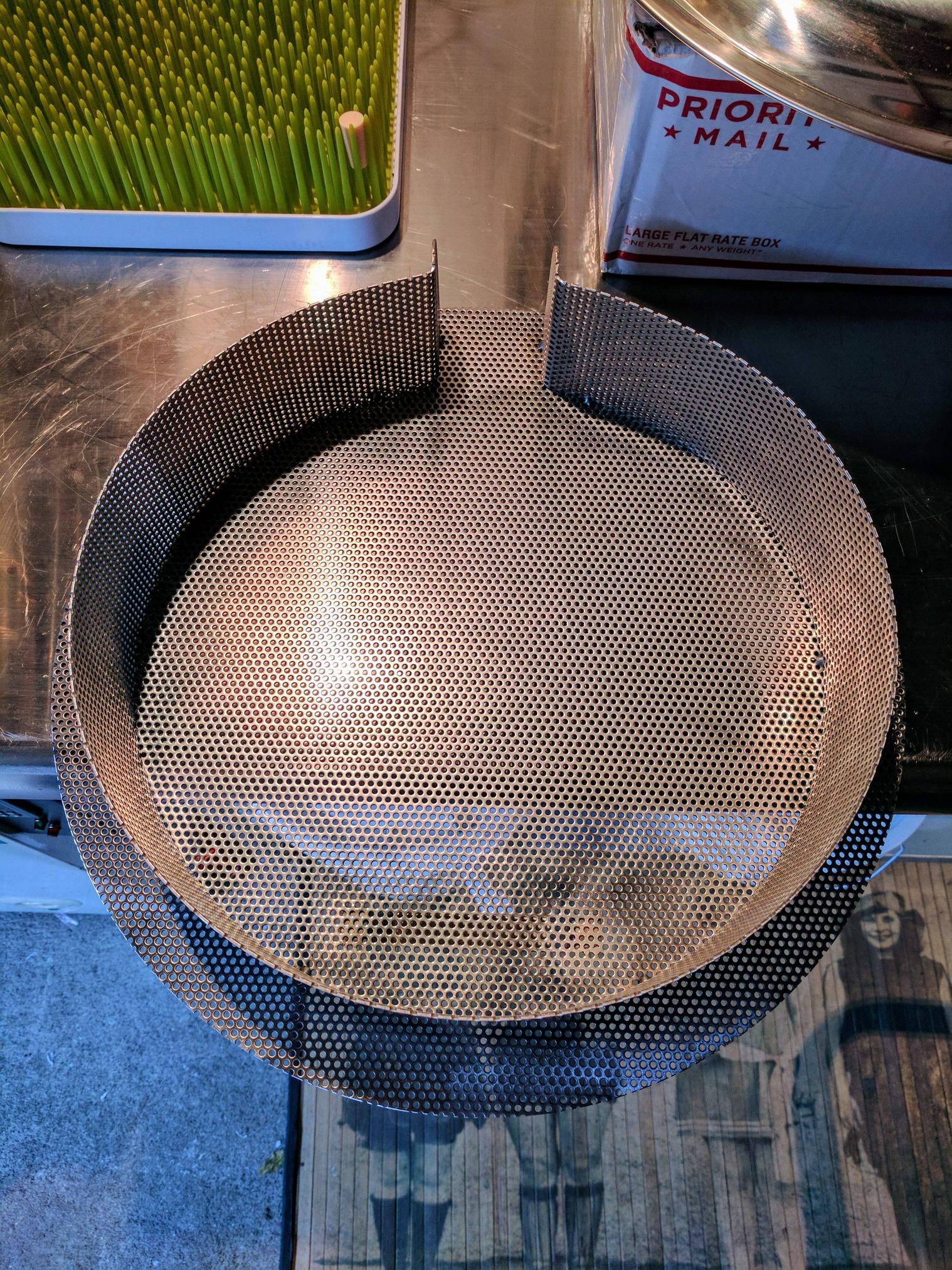

Underside of mash tun false bottom with level 2 filtration:

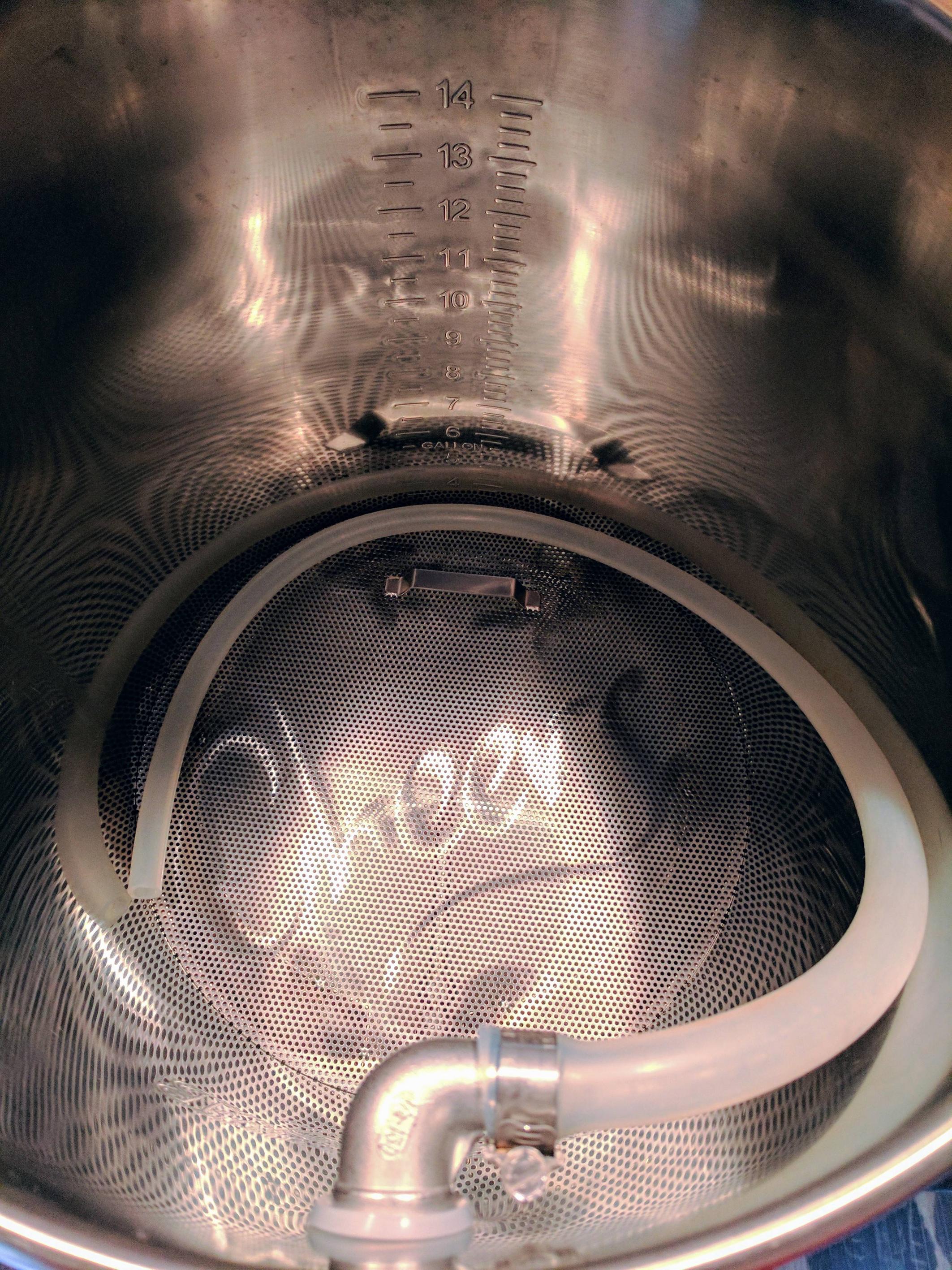

Inside of boil kettle with Norcal Brewing cut-to-length whirlpool arm and custom false bottom:

False bottom removed to show cut-to-length dip tube:

Underside of boil kettle false bottom with level 3 filtration:

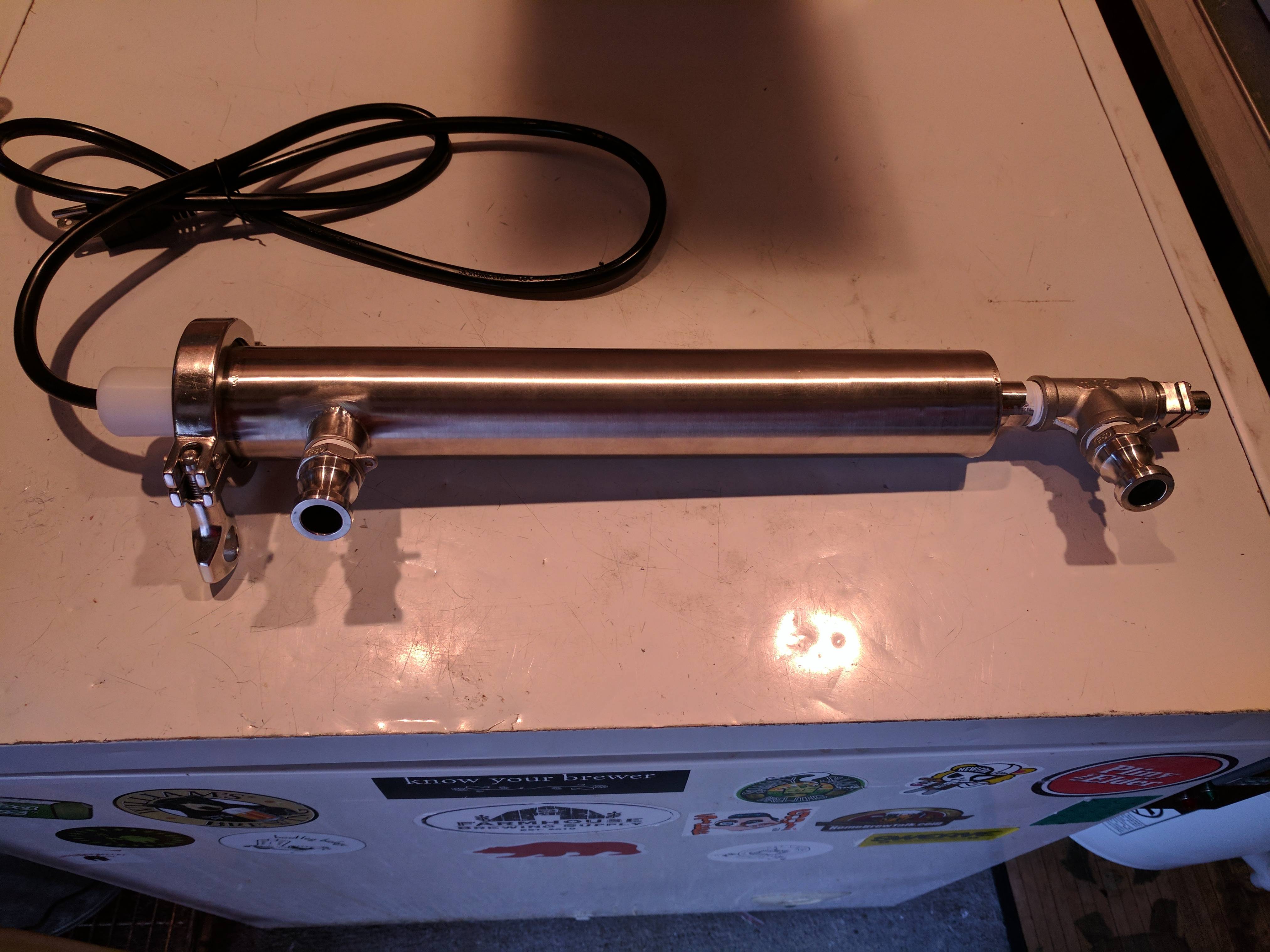

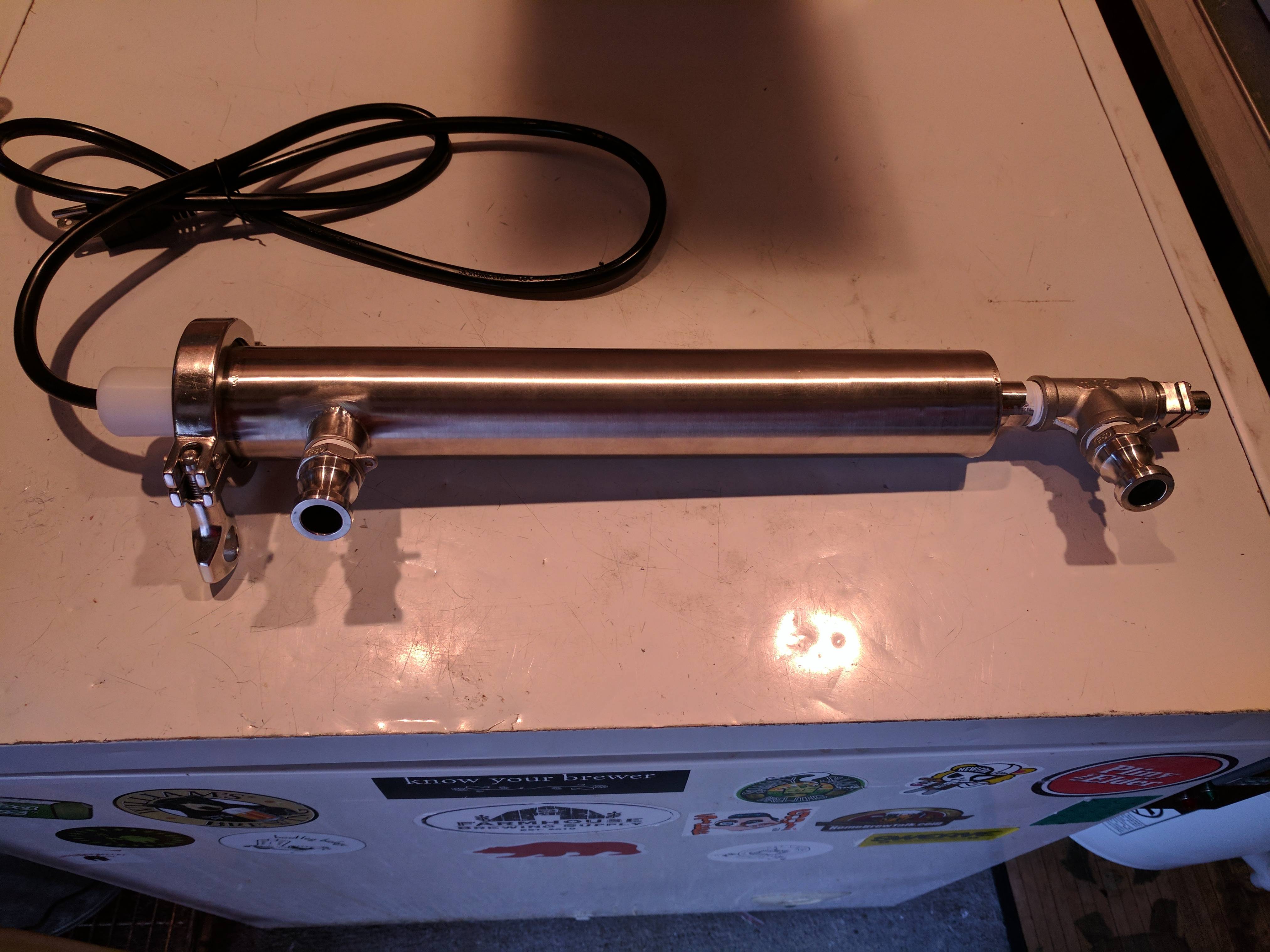

RIMS tube is the Jaybird thrifty RIMS tube with a William's Brewing 1500W 120V stainless steel heating element:

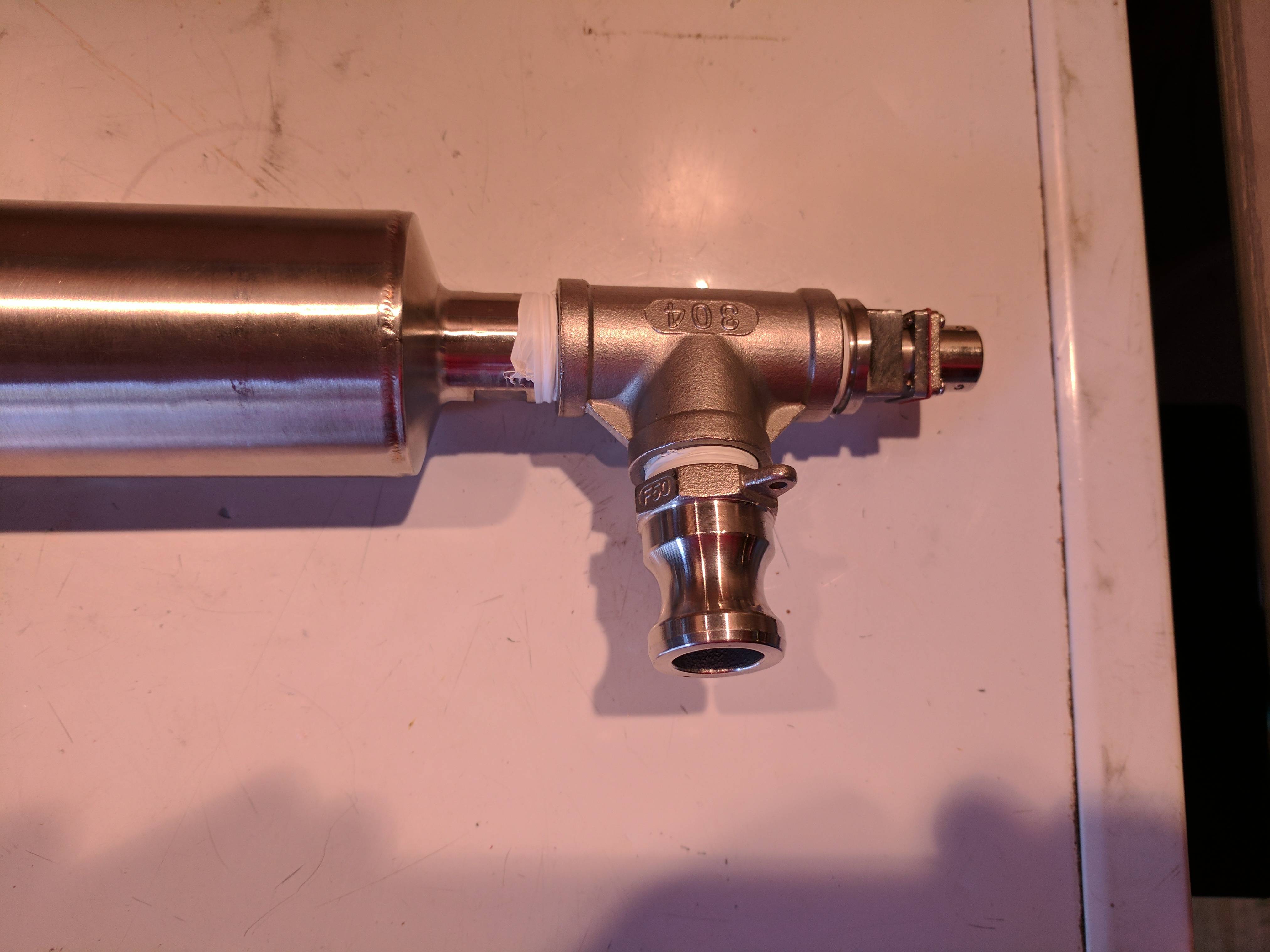

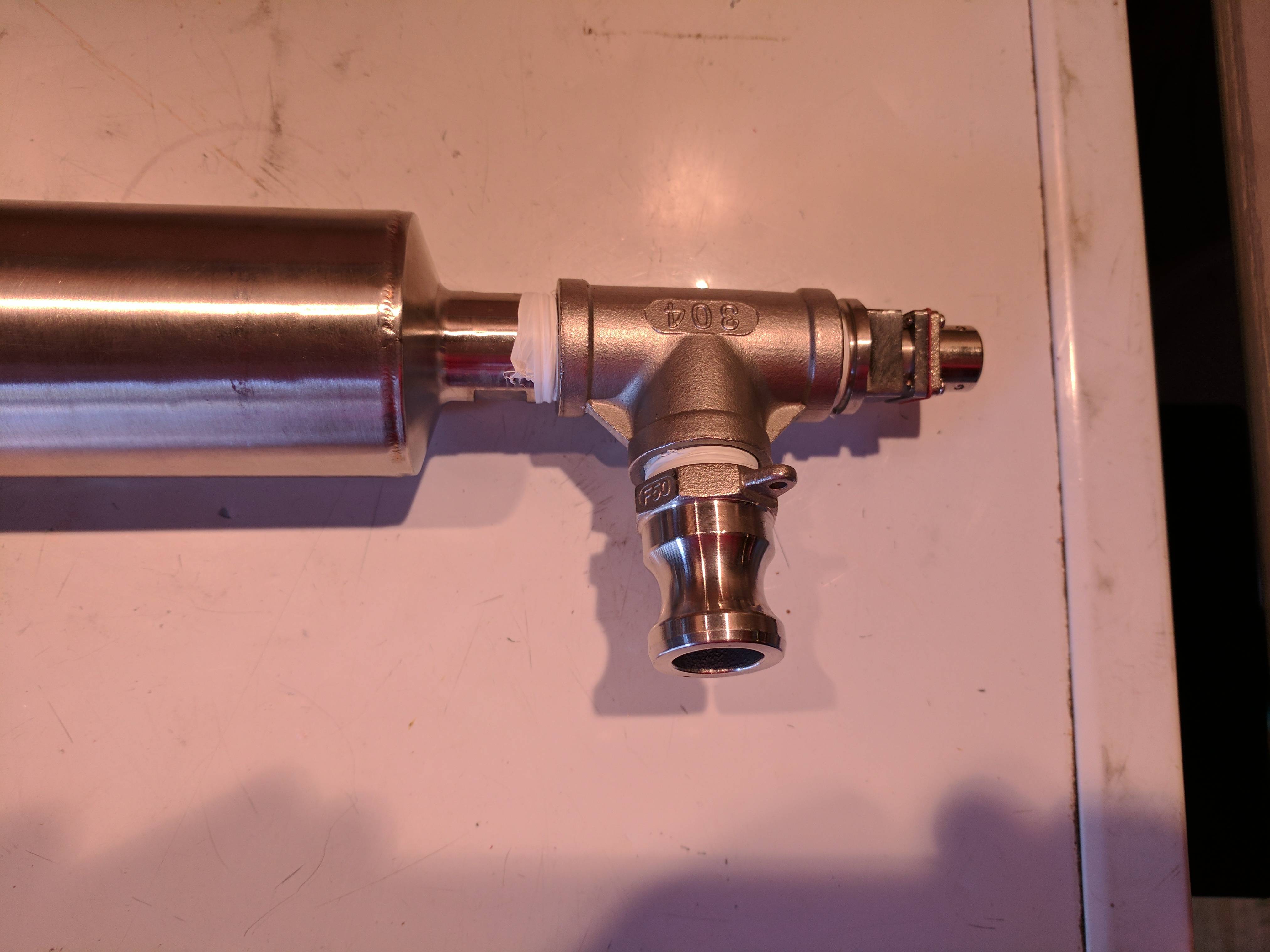

Close up of out side of the RIMS tube, stainless tee to camlock and the other part of the tee has the 1/2" temperature probe for my controller:

Duda 40-plate chiller with garden hose quick-disconnects for the water, camlocks for the wort. Out side has another tee to a camlock and a thermowell to stick in my Thermapen thermometer:

Pump is a center inlet stainless steel chugger pump. I repurposed the heat shields that came with the kettles and some other hardware I had laying around to make a stainless mounting plate and pump cover:

Blichmann 140,000 BTU Hellfire burner should heat up strike water and get things to a boil quickly:

Brau-Supply 120V EZboil RIMS controller should have no problem maintaining mash temps and has the on/off switch for the pump:

For the actual brew cart I'm using the Regency stainless wire shelving, utility cart handles, and casters. I used the Regency hanger rails to mount the RIMS tube and plate chiller up higher on the stand:

RIMS tube is mounted using 2" U-bolts, and I mounted it off center on the rig so I can access the tri-clover fitting to remove the element easily for cleaning:

Plate chiller is mounted on the other side using the built-in bolts and 1 1/4" fender washers on the inside to keep it in place:

Pump mounts to the bottom shelf with some 1/4" bolts and fender washers on the underside:

Still to-do is figure out how to mount the controller on the brew stand. If anyone has any ideas on that, I'd love to hear them. I'm looking into clamp on camera mounts and trying to mount it to the handle, but not having much luck going down that route. The other alternative is to mount it on the bottom shelf with some sort of plastic box covering it.

Once I figure that out then I can do the cable management and wrap it all up.

Wanted to give a big shoutout to @Jaybird for his help with the RIMS tube and false bottoms. I'm blown away by the quality of the false bottoms. They fit so snuggly up against the wall of the kettle that I don't think you could slide a piece of paper in there, yet at the same time they just slip right into place.

I'm hoping to get it all wrapped up and give it a test run next weekend!

Here is what everything looks like together:

Here is what everything looks like together:

One kettle serves double duty as the HLT & BK while the other is the mash tun. Both are 15 gallon Bayou Classic kettles where I drilled a 2nd hole for the whirlpool and recirculation ports. 3-piece ball valves and camlock fittings all the way around:

Inside of mash tun with simple recirculation setup and Norcal Brewing Solutions custom false bottom:

Mash tun false bottom removed to show the Norcal Brewing cut-to-length dip tube:

Underside of mash tun false bottom with level 2 filtration:

Inside of boil kettle with Norcal Brewing cut-to-length whirlpool arm and custom false bottom:

False bottom removed to show cut-to-length dip tube:

Underside of boil kettle false bottom with level 3 filtration:

RIMS tube is the Jaybird thrifty RIMS tube with a William's Brewing 1500W 120V stainless steel heating element:

Close up of out side of the RIMS tube, stainless tee to camlock and the other part of the tee has the 1/2" temperature probe for my controller:

Duda 40-plate chiller with garden hose quick-disconnects for the water, camlocks for the wort. Out side has another tee to a camlock and a thermowell to stick in my Thermapen thermometer:

Pump is a center inlet stainless steel chugger pump. I repurposed the heat shields that came with the kettles and some other hardware I had laying around to make a stainless mounting plate and pump cover:

Blichmann 140,000 BTU Hellfire burner should heat up strike water and get things to a boil quickly:

Brau-Supply 120V EZboil RIMS controller should have no problem maintaining mash temps and has the on/off switch for the pump:

For the actual brew cart I'm using the Regency stainless wire shelving, utility cart handles, and casters. I used the Regency hanger rails to mount the RIMS tube and plate chiller up higher on the stand:

RIMS tube is mounted using 2" U-bolts, and I mounted it off center on the rig so I can access the tri-clover fitting to remove the element easily for cleaning:

Plate chiller is mounted on the other side using the built-in bolts and 1 1/4" fender washers on the inside to keep it in place:

Pump mounts to the bottom shelf with some 1/4" bolts and fender washers on the underside:

Still to-do is figure out how to mount the controller on the brew stand. If anyone has any ideas on that, I'd love to hear them. I'm looking into clamp on camera mounts and trying to mount it to the handle, but not having much luck going down that route. The other alternative is to mount it on the bottom shelf with some sort of plastic box covering it.

Once I figure that out then I can do the cable management and wrap it all up.

Wanted to give a big shoutout to @Jaybird for his help with the RIMS tube and false bottoms. I'm blown away by the quality of the false bottoms. They fit so snuggly up against the wall of the kettle that I don't think you could slide a piece of paper in there, yet at the same time they just slip right into place.

I'm hoping to get it all wrapped up and give it a test run next weekend!