I’ve found that some of the most active DIY threads revolve around fermentation control, be it with Fermentrack, BrewPi Remix, BrewPi Less, etc. These threads are a huge trove of information and great resources. The one thing I noticed, not too many build threads. For a novice like me, I love the build threads. I thought I would just take the time to share my experience as I built my Fermentrack Control Panel.

This should go without saying, but please use the following references as the “go to” authority for all things Fermentrack.

fermentrack.com

docs.fermentrack.com/en/master

GitHub.com/thorrak/Fermentrack

YouTube.com (Optictheory)

My build can be broken down into 4 major phases. I am not going to spend much time talking about Phases 1 and 4. Those are extremely well documented, but I will add some tidbits from my experience that may help someone out along the way.

Phases:

B.O.M.

This should go without saying, but please use the following references as the “go to” authority for all things Fermentrack.

fermentrack.com

docs.fermentrack.com/en/master

GitHub.com/thorrak/Fermentrack

YouTube.com (Optictheory)

My build can be broken down into 4 major phases. I am not going to spend much time talking about Phases 1 and 4. Those are extremely well documented, but I will add some tidbits from my experience that may help someone out along the way.

Phases:

- RaspberryPi Set-Up/Fermentrack Installation

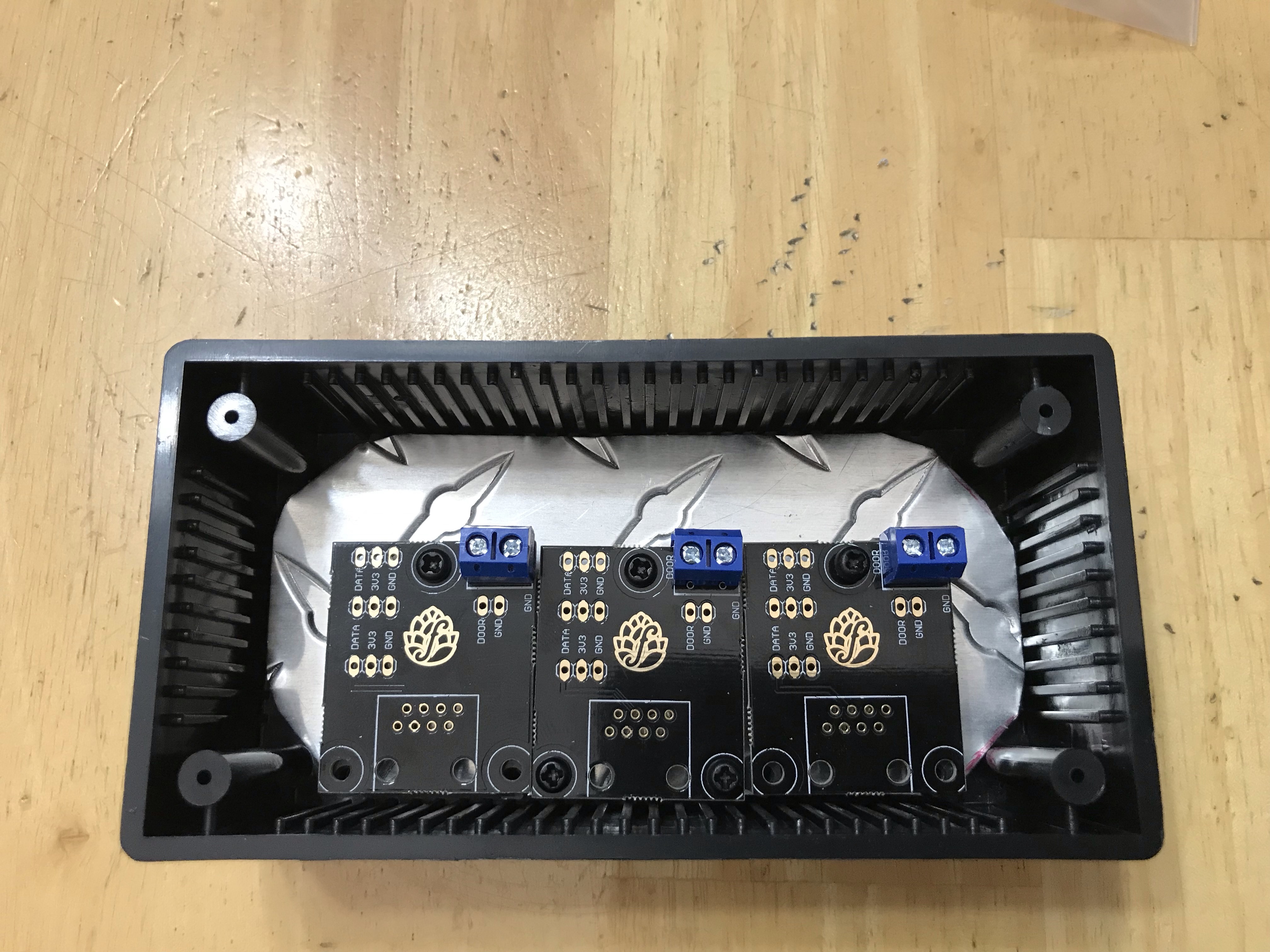

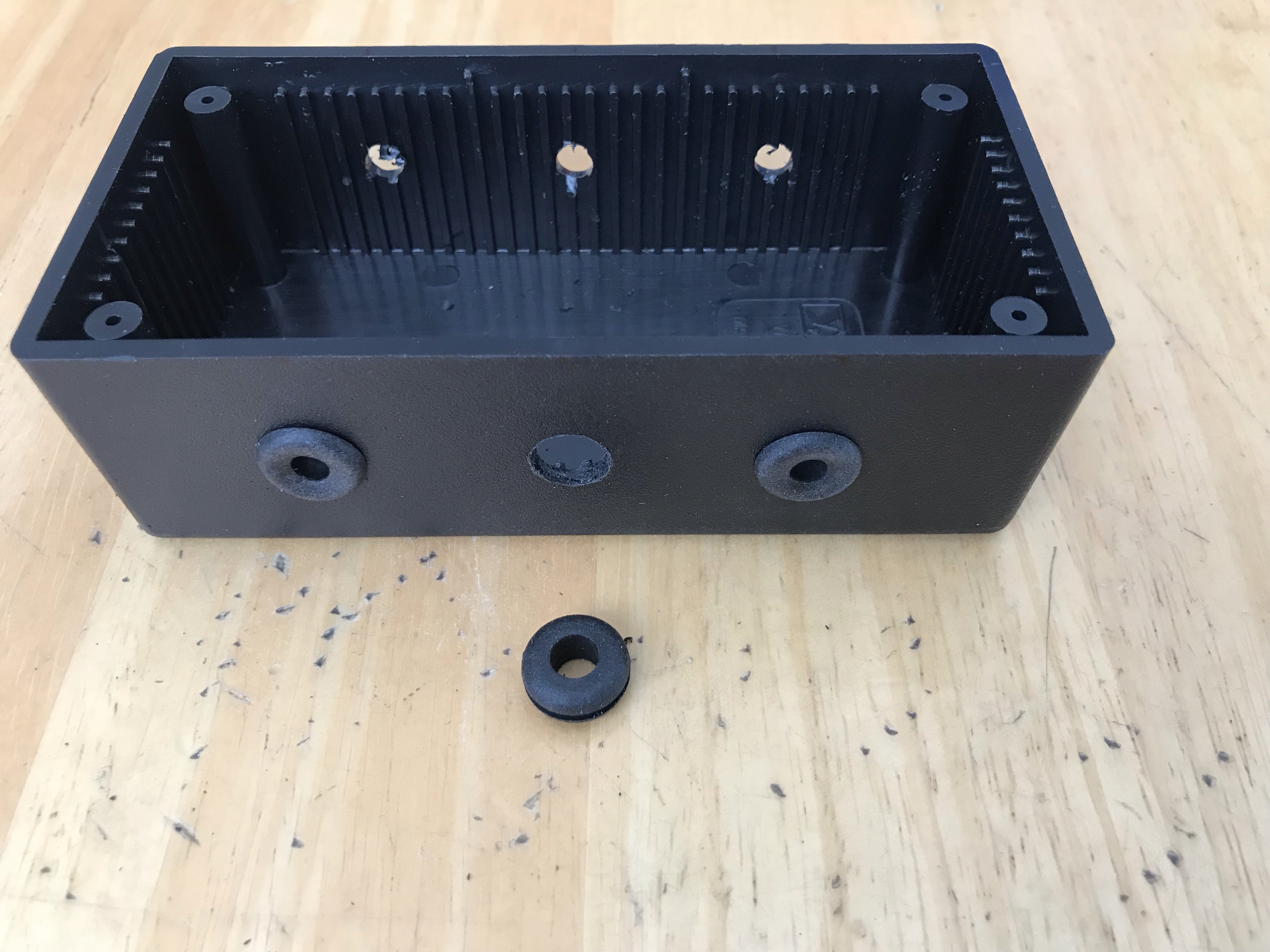

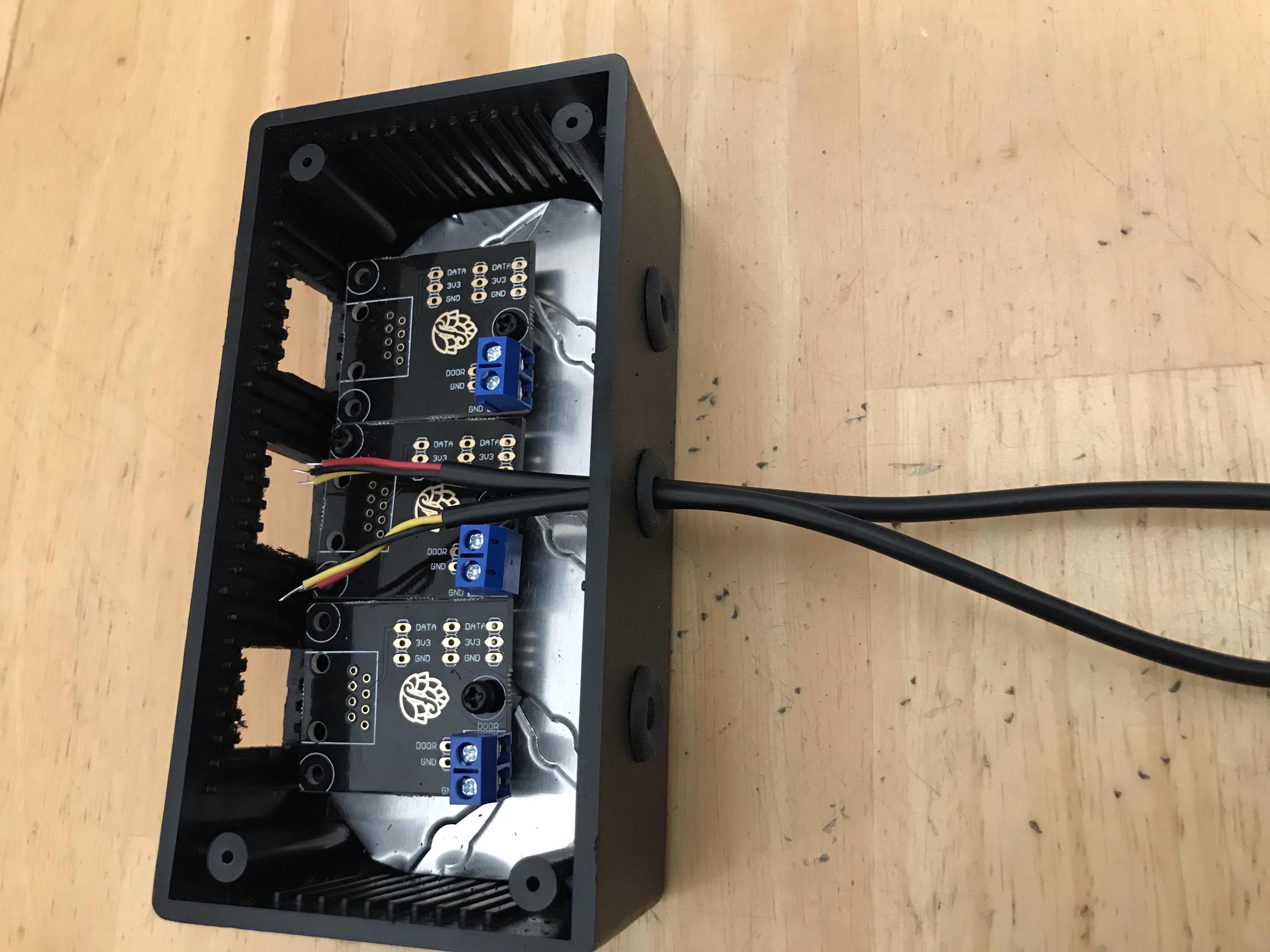

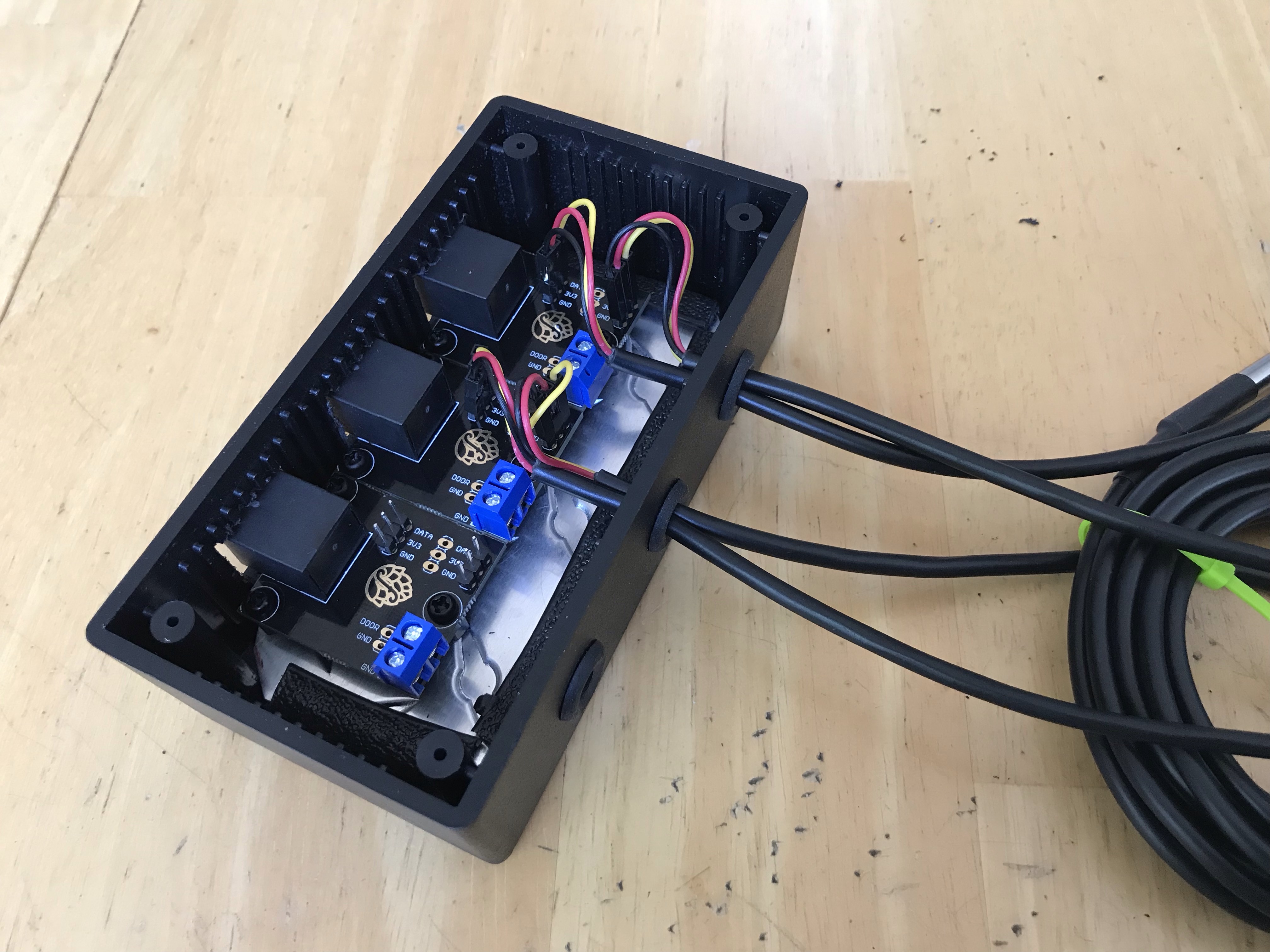

- RJ45 Breakout Board Control Box Build

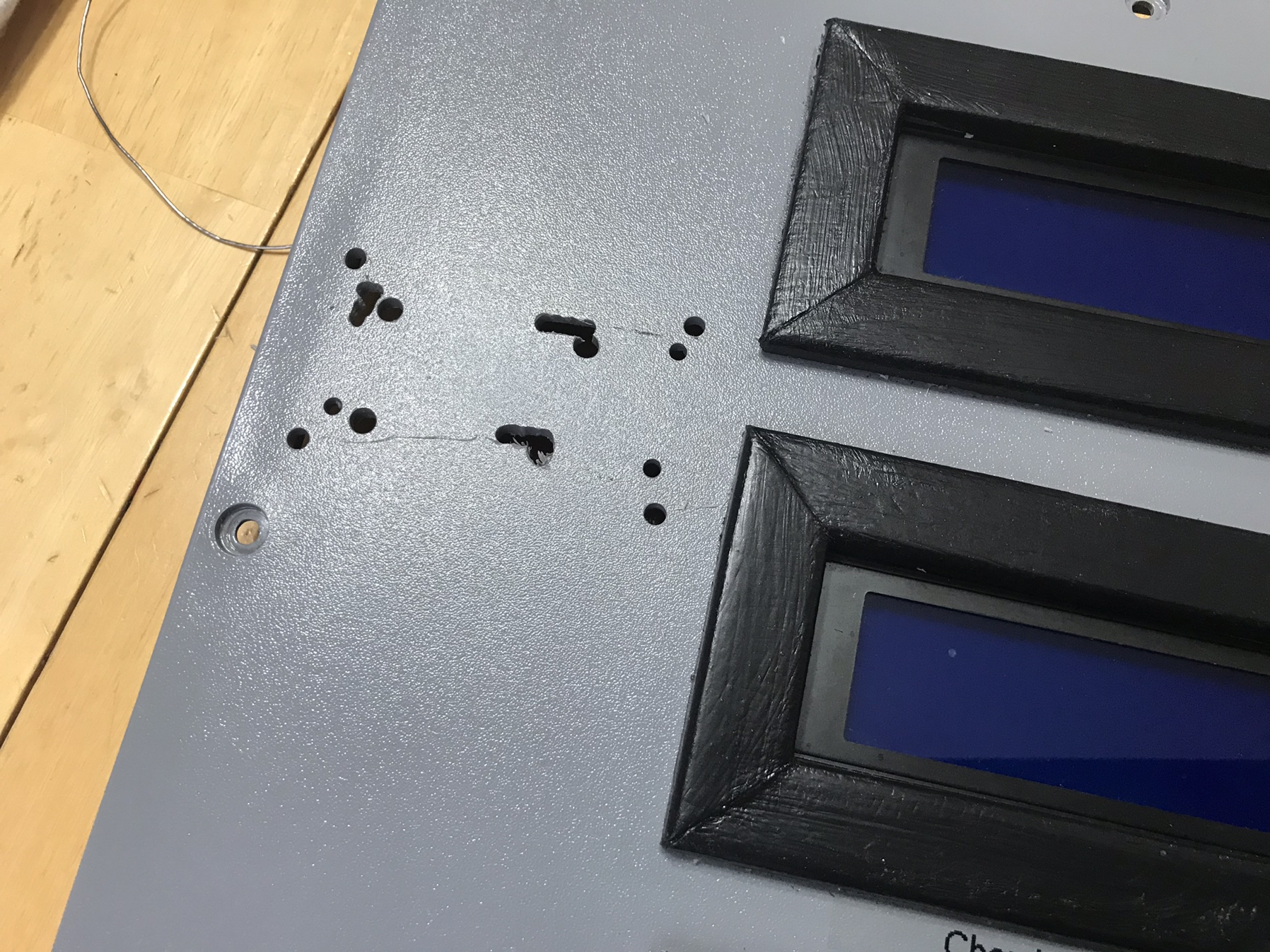

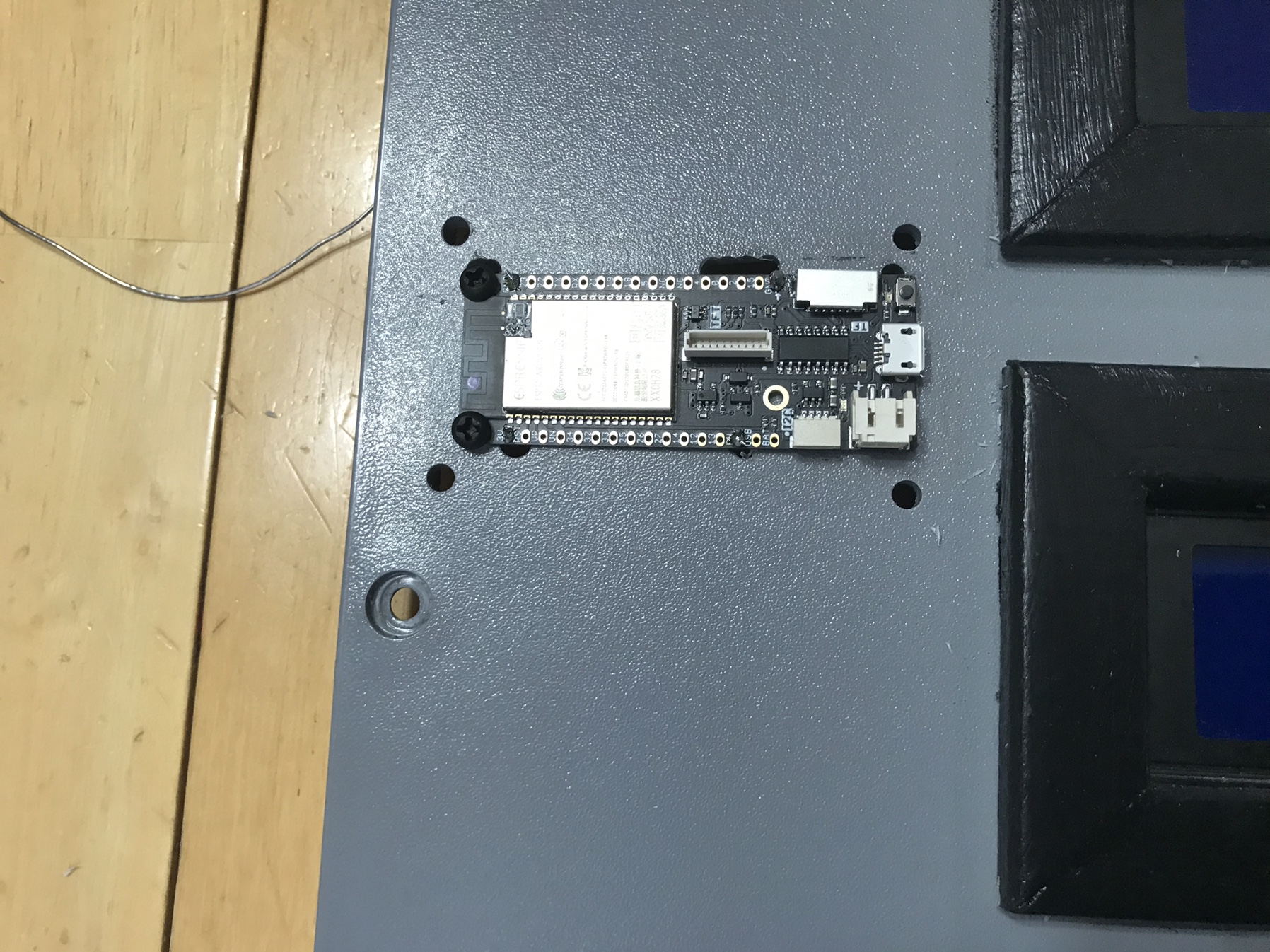

- 3 Instance Main Control Box Build

- Controller Flashing/Controller WiFi Connection Set-up/Add Temp Controller

B.O.M.

- ESP8266 Breakout Board for BrewPi - SMD w/ LCD & RJ45 v1.0 (pcbs.io)

- RJ45 Sensor Breakout v1.0 for ESP8266-based BrewPi controllers (pcbs.io)

- New High quality AC 100-265V to DC 5V 2A Switching Power Supply Module TL431(AliExpress)

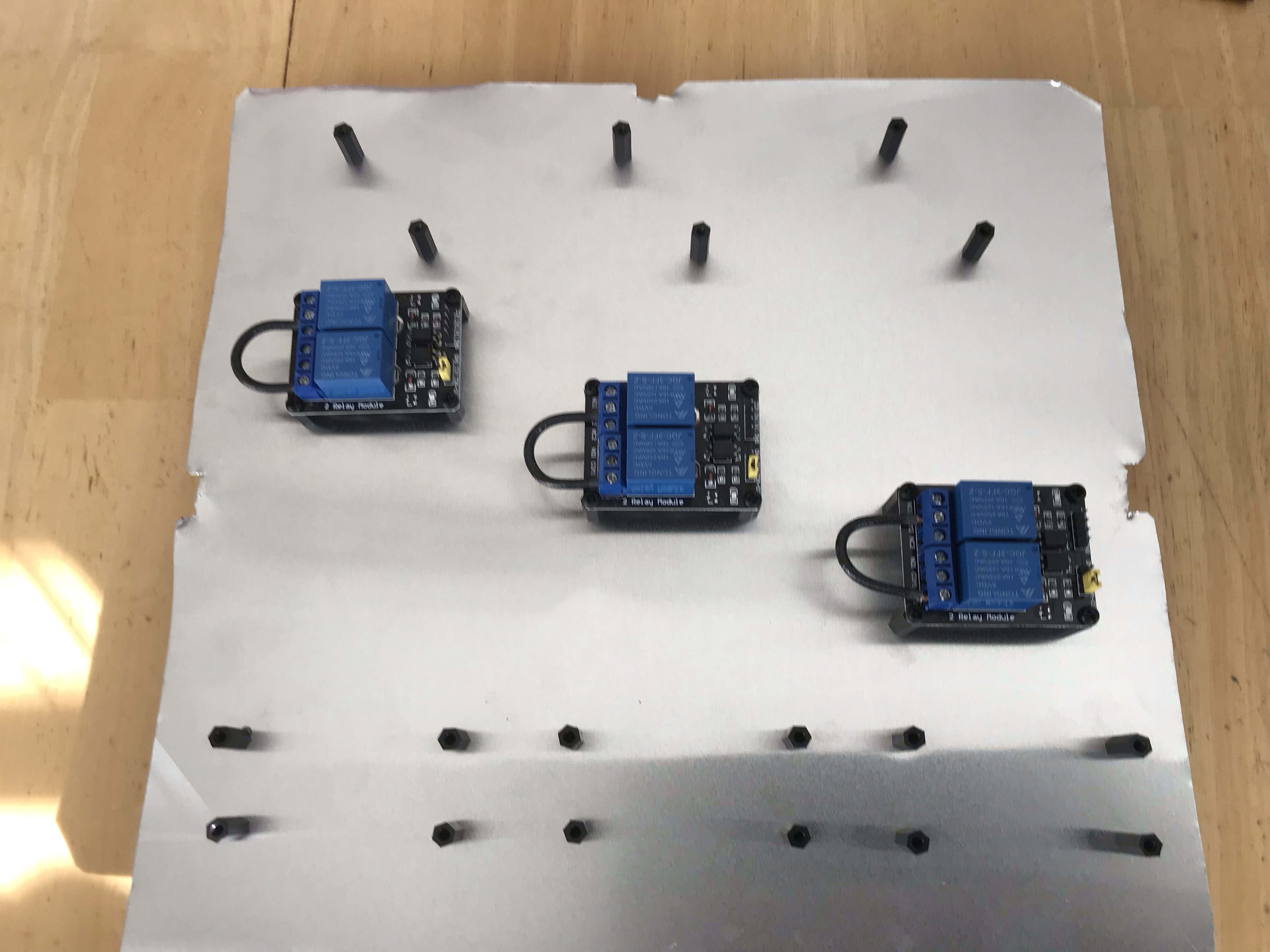

- 2 channel relay module 5V 2-channel relay modules 5VDC 2 road relay module control board with optocoupler (AliExpress)

- Character LCD Display Module 20x4 LCD2004 IIC/I2C/TWI 2004 Display PCF8574 for Arduino Uno r3 Mega 2560 Raspberry Pi Avr Stm32 (AliExpress)

- LOLIN D1 mini V3.1.0 - WEMOS WIFI Internet of Things development board based ESP8266 4MB MicroPython Nodemcu Arduino Compatible (AliExpress)

- 3M DS18B20 Digital Temperature Temp Sensor Probe Thermometer Waterproof Sensor Compatible For Arduino Stainless Steel (AliExpress)

- 5.08-301-2P 301-2P 2 Pin Screw Terminal Block Connector 5mm Pitch (AliExpress)

- 1206 SMD capacitor 100uf 16V 107Z X7R (AliExpress)

- 0805 SMD 1/4W 0R ~ 10M chip resistor 4.7K (AliExpress)

- 0805 SMD 1/4W 0R ~ 10M chip resistor 10K (AliExpress)

- BSS138LT1G BSS138 SOT23 SOT SOT23-3 MOSFET SMD (AliExpress)

- Single Row Male and Female 2.54 Breakable Pin Header PCB JST Connector Strip (AliExpress)

- Dupont Line 30CM Female to Female Jumper Wire Dupont Cable (AliExpress)

- Black 3 Pins IEC320 C14 Inlet Power Plug Socket AC 250V 10A (AliExpress)

- US 3 Pin Power Socket Panel Receptacle AC125V 15A, UL Cert (AliExpress)

- RJ45 8P8C Black Computer Internet Network PCB Jack Socket (AliExpress)

- Keystone Plates (Frys Electronics)

- USB Keystone Jack Inserts (Amazon)

- RJ45 Keystone Jack Inserts (Frys Electronics)

- 1ft Ethernet Patch Cables (Frys Electronics)

- 3ft Ethernet Patch Cables (Frys Electronics)

- USB Male A to Micro USB B Male Cable (Frys Electronics)

- NEMA 5-15P/C13 Power Cord (Frys Electronics)

- USB Male A to USB Male A Cable (Amazon)

- Push-In Wire Connectors (Home Depot)

- AMP Female Disconnects (Home Depot)

- 14AWG Solid Strand Wire (Black, White, and Green) (Home Depot)

- 12in x 12in x 6in Junction Box (Home Depot)

- 5in x 3in x 2in Project Box (Micro Center)

- M3 Nylon Screws and Nuts (Micro Center)

- RaspberryPi 3B+ w/ Power Cord, SD Card & Case (Micro Center)

- Back-up SD Card (Micro Center)