Michele Craft

Well-Known Member

- Joined

- Dec 4, 2019

- Messages

- 133

- Reaction score

- 39

Hi all,

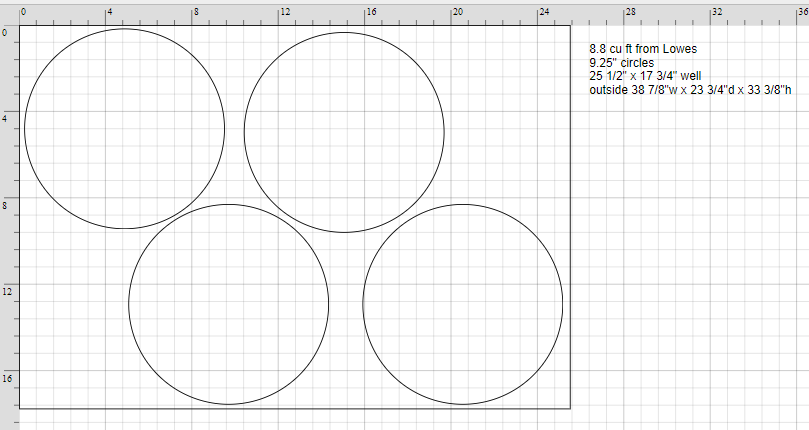

Thank you to those who talked me out of buying that 7cu ft freezer I saw and confirmed I could NOT get 4 1/6s in it.

I've been looking through this thread

https://www.homebrewtalk.com/forum/threads/chest-freezer-specs-and-layouts.377518/page-18

and I'm now neck deep in web browser tabs trying to figure out what I REALLY need.

1.) Can anyone suggest a reasonably priced and readily available (i.e. currently available) chest freezer where I could fit 4 1/6s in it and put the CO2 on the hump. I'd LIKE to stay with a 7 cu ft but can go to a 10'ish if need be. Reason I'm stuck on sizes.....

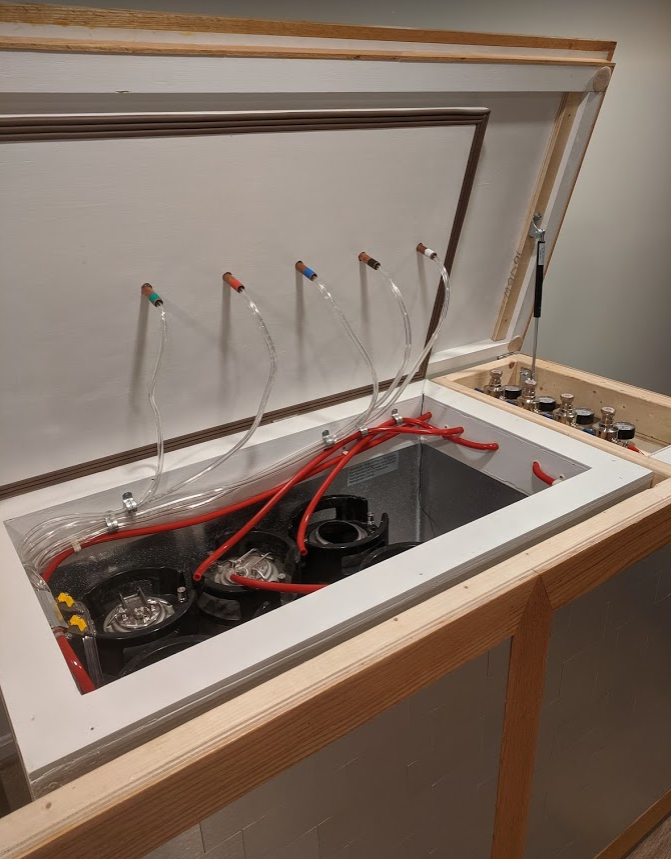

We are putting in a home bar, front bar (tbd if it'll be an "island" or anchored to the wall on one side) with a back bar. My intent is to put the keezer on rollers and make it the centerpiece of the back bar. So I'm thinking build some shelving for the back bar, some with doors some not, put the keezer in the middle of it and try to match the height of the wood counters on either side and then put a wood top on the keezer. I won't wrap the back of it but because it'll likely be deeper than the counter top, I need to do the sides because it'll stick out some.

2.) Next question.... my plan was to do the 4 taps with 2" black iron pipe. So 10 or 12" rise, elbow, close, T, close, T etc.... elbow down, 10 or 12 back down to top. Knowing I'll have to roll it out a bit from the wall, does anyone think putting that much black iron on top of a lid (TBD if I'll use the existing freezer lid or just make one out of wood to sit above any collar needed) is too heavy? I feel like black iron is about 4.5# / ft. I could put a gas shock assist with the lift I suppose. Maybe a single riser with 2 off each side is the way to go?

3.) Tower cooling.... I've been trying to read and what I've learned is I don't need glycol LOL! I've read some people use flexible copper tubing as a "heat sink" and call it good. Others have a 1" hose with a fan blowing up into it. That seems like my best bet BUT I don't know if I should just run it up to one elbow and let it blow across and down the other side or what. If I build it with the 2 risers and 2 elbows, I don't know if I should put 2 lines up 1 side and 2 up the other thus (I think) needing two air cooling lines. Or if I do a T, just blow it up the middle....... Hoping for some help there.

At this point, the only thing I'm sure of is that I need to find short shanks and I'm going with the Perlick taps because I want to only deal with this once.

thanks so much in advance for any help/suggestions/watch outs you can offer.

Thank you to those who talked me out of buying that 7cu ft freezer I saw and confirmed I could NOT get 4 1/6s in it.

I've been looking through this thread

https://www.homebrewtalk.com/forum/threads/chest-freezer-specs-and-layouts.377518/page-18

and I'm now neck deep in web browser tabs trying to figure out what I REALLY need.

1.) Can anyone suggest a reasonably priced and readily available (i.e. currently available) chest freezer where I could fit 4 1/6s in it and put the CO2 on the hump. I'd LIKE to stay with a 7 cu ft but can go to a 10'ish if need be. Reason I'm stuck on sizes.....

We are putting in a home bar, front bar (tbd if it'll be an "island" or anchored to the wall on one side) with a back bar. My intent is to put the keezer on rollers and make it the centerpiece of the back bar. So I'm thinking build some shelving for the back bar, some with doors some not, put the keezer in the middle of it and try to match the height of the wood counters on either side and then put a wood top on the keezer. I won't wrap the back of it but because it'll likely be deeper than the counter top, I need to do the sides because it'll stick out some.

2.) Next question.... my plan was to do the 4 taps with 2" black iron pipe. So 10 or 12" rise, elbow, close, T, close, T etc.... elbow down, 10 or 12 back down to top. Knowing I'll have to roll it out a bit from the wall, does anyone think putting that much black iron on top of a lid (TBD if I'll use the existing freezer lid or just make one out of wood to sit above any collar needed) is too heavy? I feel like black iron is about 4.5# / ft. I could put a gas shock assist with the lift I suppose. Maybe a single riser with 2 off each side is the way to go?

3.) Tower cooling.... I've been trying to read and what I've learned is I don't need glycol LOL! I've read some people use flexible copper tubing as a "heat sink" and call it good. Others have a 1" hose with a fan blowing up into it. That seems like my best bet BUT I don't know if I should just run it up to one elbow and let it blow across and down the other side or what. If I build it with the 2 risers and 2 elbows, I don't know if I should put 2 lines up 1 side and 2 up the other thus (I think) needing two air cooling lines. Or if I do a T, just blow it up the middle....... Hoping for some help there.

At this point, the only thing I'm sure of is that I need to find short shanks and I'm going with the Perlick taps because I want to only deal with this once.

thanks so much in advance for any help/suggestions/watch outs you can offer.