- Joined

- Feb 20, 2011

- Messages

- 395

- Reaction score

- 92

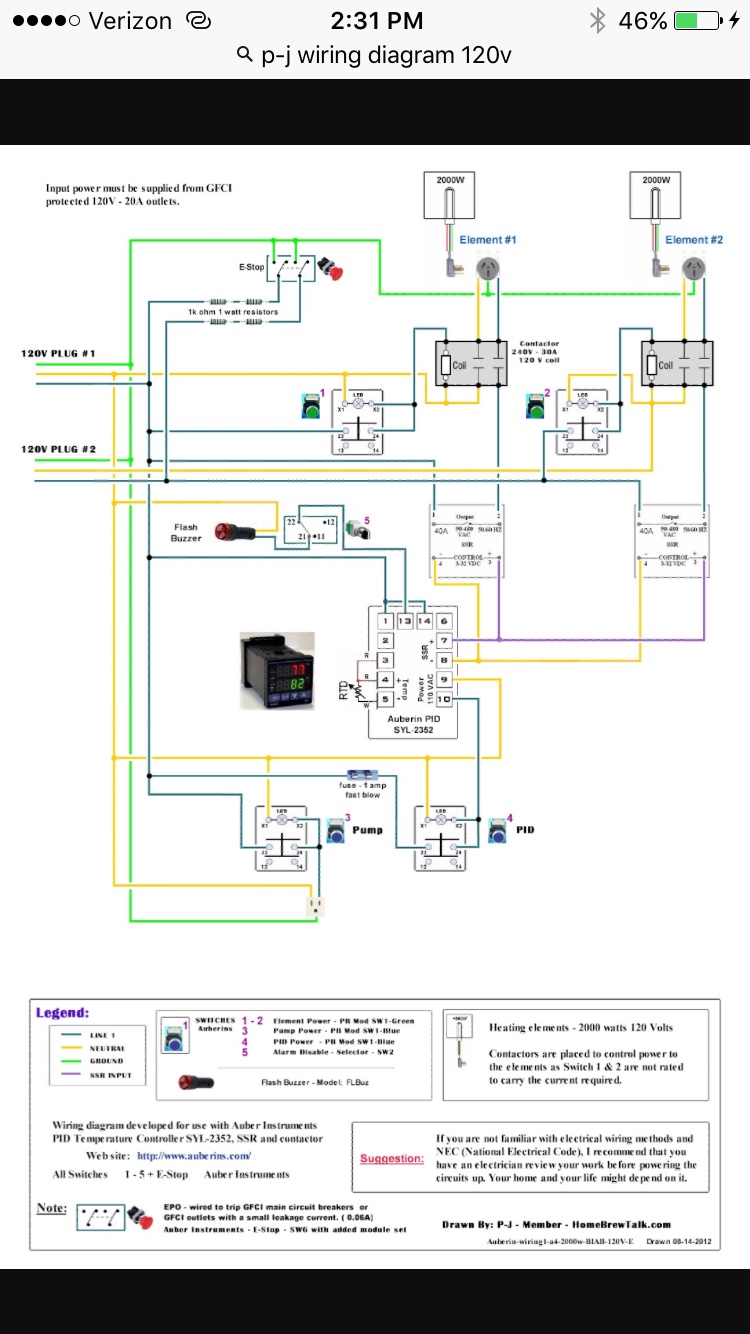

I just finished wiring up my 2 element 2 120v circuit panel. How can I use a multimeter to ensure everything is wired correctly? I’ve used the continuity function to check all the switches, terminal blocks, and to make sure the 2 circuits aren’t bonded anywhere. Are there any other functions to use?