mrstevenund

Well-Known Member

Instead of reviving my old thread, I'll start a new one. Old Thread: https://www.homebrewtalk.com/showthread.php?t=401345

Well, I purchased the mill way back in 2011. From the start, I had the idea of the garage door opener. There always seemed to be something getting between me and purchasing a motor to complete the project. Had a cross country move happen in 2013 and all my equipment went into storage for a time.

As in the original thread, I came across a screw drive garage door opener, reverse engineered it, and found out it was way too fast to even bother gearing down. 2015 I came across a broken Craftsman chain drive opener (chain sprocket sheered off due to broken bushing). It ended up being perfect speed off the worm gear, so I hatched a plan to finally get it up and running. Below pictures of the nearly final product.

TL: DR: Bought a MM2 in 2011, didn't have a plan for long time. 6 years later, have a working mill.

Images Below:

1) Front view. I have a small gap between the top of the bucket and the mill. Sides and top are OSB, internal structure is 2x2 or 1x2.

2) Back View. As you can see, just a garage door unit here. The cover still needs to go on. Original circuit board and limit switches have been removed. The motor is turned on and off through a relay board on the upper left of the motor assembly (white patch is the double stick tape, board fell down).

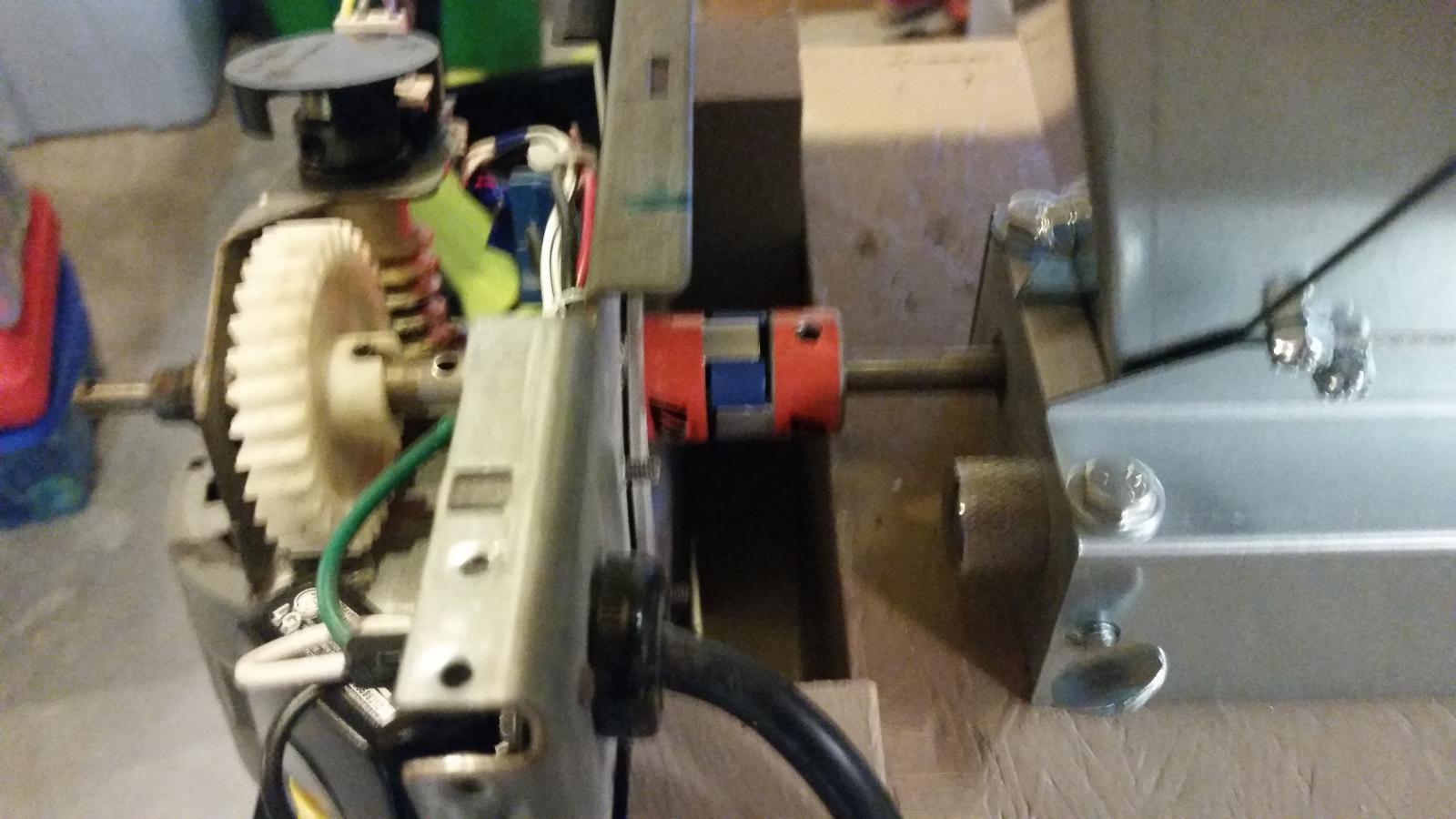

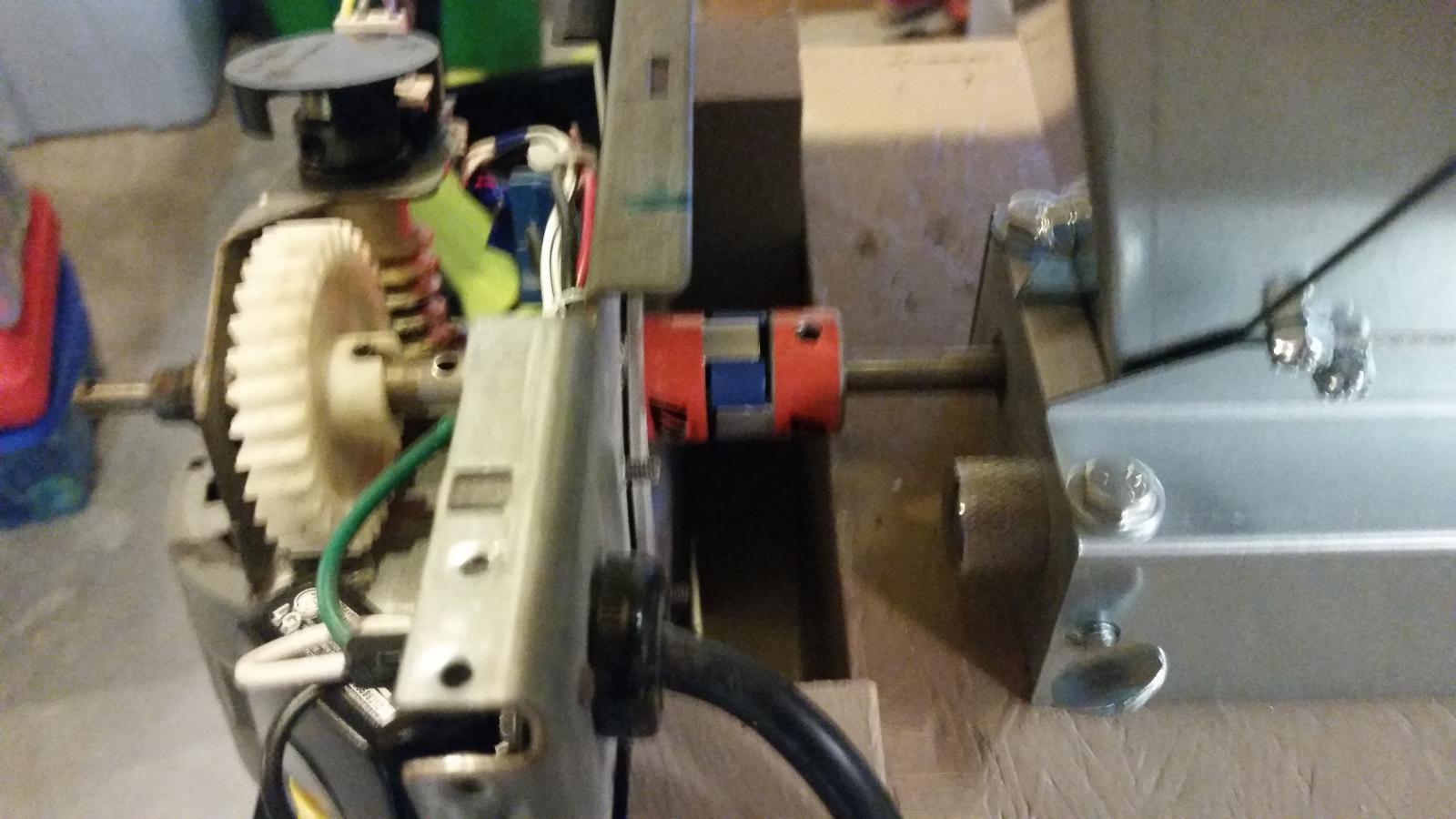

3) Lovejoy connection. I cleaned up the end where the sprocket should be and replaced it with a lovejoy connection to the mill.

4) Motor top. Relay board has the light. An old cell phone adapter wired into the power in for the low voltage relays and switches.

So far, So good. This took way too long to start, let alone finish. Few minor things to finish up like a fan to keep the motor cooler, and maybe an RPM sensor (kept the original optical sensor on the gear assembly).

I plan on milling my first batch and brewing on Sunday.

Well, I purchased the mill way back in 2011. From the start, I had the idea of the garage door opener. There always seemed to be something getting between me and purchasing a motor to complete the project. Had a cross country move happen in 2013 and all my equipment went into storage for a time.

As in the original thread, I came across a screw drive garage door opener, reverse engineered it, and found out it was way too fast to even bother gearing down. 2015 I came across a broken Craftsman chain drive opener (chain sprocket sheered off due to broken bushing). It ended up being perfect speed off the worm gear, so I hatched a plan to finally get it up and running. Below pictures of the nearly final product.

TL: DR: Bought a MM2 in 2011, didn't have a plan for long time. 6 years later, have a working mill.

Images Below:

1) Front view. I have a small gap between the top of the bucket and the mill. Sides and top are OSB, internal structure is 2x2 or 1x2.

2) Back View. As you can see, just a garage door unit here. The cover still needs to go on. Original circuit board and limit switches have been removed. The motor is turned on and off through a relay board on the upper left of the motor assembly (white patch is the double stick tape, board fell down).

3) Lovejoy connection. I cleaned up the end where the sprocket should be and replaced it with a lovejoy connection to the mill.

4) Motor top. Relay board has the light. An old cell phone adapter wired into the power in for the low voltage relays and switches.

So far, So good. This took way too long to start, let alone finish. Few minor things to finish up like a fan to keep the motor cooler, and maybe an RPM sensor (kept the original optical sensor on the gear assembly).

I plan on milling my first batch and brewing on Sunday.