- Joined

- Jul 21, 2013

- Messages

- 1,317

- Reaction score

- 305

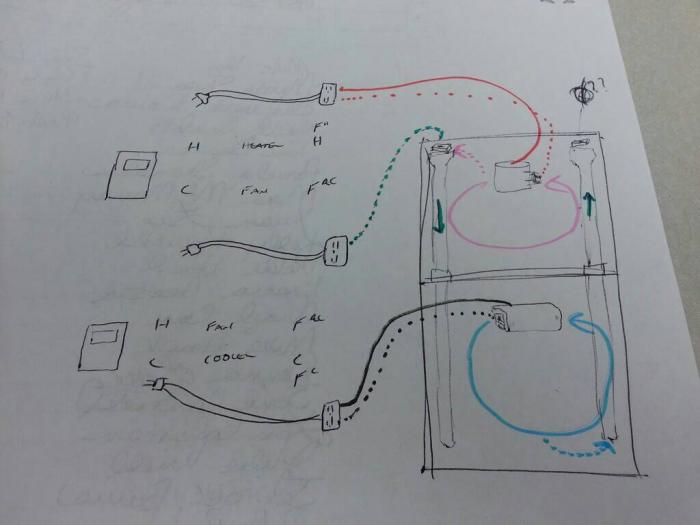

Ok, there are lots of very fancy set ups here and I have been learning a lot from all the guys that have gone before. This one is not going to be fancy. This is not going to be high end, it is going to be my first experiment.

This is the kind of fridge I have been keeping my eye open for at the surplus/used appliance place.

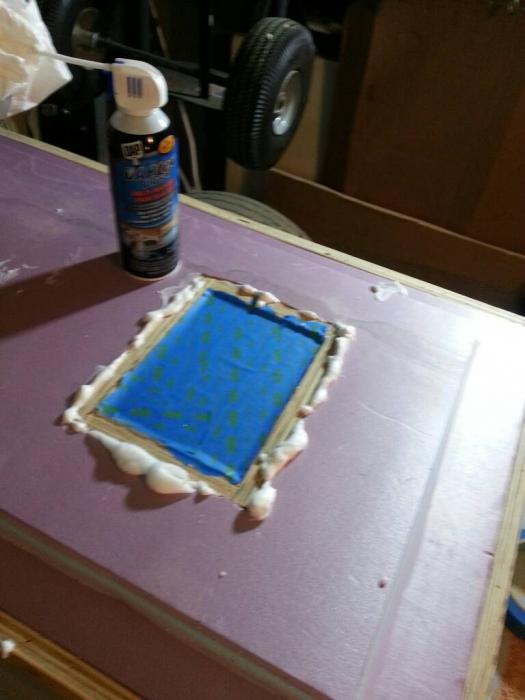

Saw this in one post, so I attempted to do the same, just cut a path to get the freezer section out of fridge.

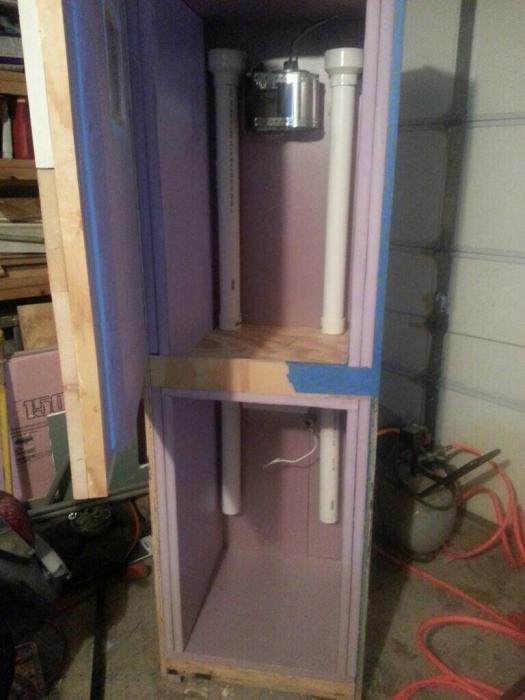

And then...TADA...freezer guts.

Build Notes:(It appears I can still edit this post, so been planning to throw some lessons learned in this thread somewhere.)

Lessons Learned -

- I planned and build using 1" pink foam board. Took a while to realize that 2" foam board would have been less cost total, and I wouldn't have uneven front edges where the 1"'rs line up.

- I got hung up on trying to figure out how to get the door to fit into the sides, like on a fridge. That angle there. Instead I should have just build the door 2" deep. That would have allowed it to just close flush over the opening and still be insulated out past the interior foamboard. (Would have make hinges easier too.)

- Cutting foam board needs to take time! My first few cuts I tried to make in one shot. The bottom of the blade always flexed from pressure giving me weird angles and wobbly lines. I now use a hobby exacto knife. Three swipes total, one very shallow to set the line, second one to cut deeper, third one to make final seperating cut. MUCH straighter finish.

(more to come)

This is the kind of fridge I have been keeping my eye open for at the surplus/used appliance place.

Saw this in one post, so I attempted to do the same, just cut a path to get the freezer section out of fridge.

And then...TADA...freezer guts.

Build Notes:(It appears I can still edit this post, so been planning to throw some lessons learned in this thread somewhere.)

Lessons Learned -

- I planned and build using 1" pink foam board. Took a while to realize that 2" foam board would have been less cost total, and I wouldn't have uneven front edges where the 1"'rs line up.

- I got hung up on trying to figure out how to get the door to fit into the sides, like on a fridge. That angle there. Instead I should have just build the door 2" deep. That would have allowed it to just close flush over the opening and still be insulated out past the interior foamboard. (Would have make hinges easier too.)

- Cutting foam board needs to take time! My first few cuts I tried to make in one shot. The bottom of the blade always flexed from pressure giving me weird angles and wobbly lines. I now use a hobby exacto knife. Three swipes total, one very shallow to set the line, second one to cut deeper, third one to make final seperating cut. MUCH straighter finish.

(more to come)

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)

![20140315_102617-picsay[1].jpg 20140315_102617-picsay[1].jpg](https://cdn.homebrewtalk.com/data/attachments/156/156151-ddbd3e16aed1812c54a47bb860d5557b.jpg)

![20140315_121741-picsay[1].jpg 20140315_121741-picsay[1].jpg](https://cdn.homebrewtalk.com/data/attachments/156/156152-30a3241a94ddfe20bdd44b4a83b9e65d.jpg)

![20140309_160227-picsay[1].jpg 20140309_160227-picsay[1].jpg](https://cdn.homebrewtalk.com/data/attachments/156/156158-47077036cd5595c32e5d6ee494b8b652.jpg)

![20140310_183602-picsay[1].jpg 20140310_183602-picsay[1].jpg](https://cdn.homebrewtalk.com/data/attachments/156/156157-a468f61c657a5ce3a976628e28cb7c23.jpg)

![20140308_203150-picsay[1].jpg 20140308_203150-picsay[1].jpg](https://cdn.homebrewtalk.com/data/attachments/156/156159-6d04277afe048a8bcf615187ee2a4464.jpg)

![20140316_115713-picsay[1].jpg 20140316_115713-picsay[1].jpg](https://cdn.homebrewtalk.com/data/attachments/156/156162-5ef5a361e7c5d59ee05236ecece7f80f.jpg)