The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

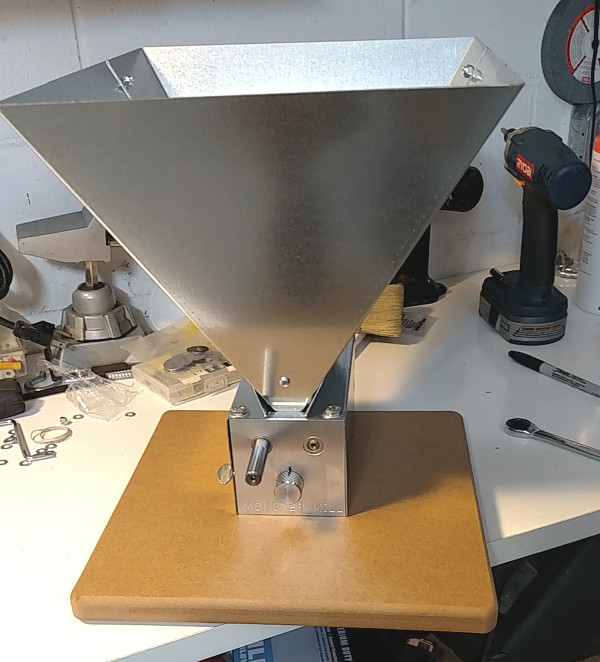

As the subject states. I currently have a Monster Mill 2 roller. I've been debating the upgrade (Is it an upgrade?) to a 3 roller mill.

Right now I condition grain and mill at .039 for my BIABasket setup. No issues with stuck recirculation, and I regularly get around 88% mash efficiency (as measured via volume of lost wort in the grains. Conversion efficiency is damn near 100%).

I'm wondering if the three roller mill would allow me to crush without conditioning and still retain the same flow through the grainbed.

Anyone have a comparison pic of grain milled at the same gap setting, 2 roller vs. 3 roller?

Right now I condition grain and mill at .039 for my BIABasket setup. No issues with stuck recirculation, and I regularly get around 88% mash efficiency (as measured via volume of lost wort in the grains. Conversion efficiency is damn near 100%).

I'm wondering if the three roller mill would allow me to crush without conditioning and still retain the same flow through the grainbed.

Anyone have a comparison pic of grain milled at the same gap setting, 2 roller vs. 3 roller?