I was reading a post by a biab brewer on mashing out when it occurred to me that with biab can't you just stop the enzymatic process by hoisting the bag? The only time I thought it might be useful is if you were going to sparge but even then it seems a waste of time. Am I missing something?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mashing out with biab

- Thread starter pretzelb

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

pricelessbrewing

Brewer's Friend Software Manager

My thoughts exactly. I never both with it, don't see the point unless you have a very long sparging process, and even then you'd be better off extending the mash imo to ensure complete conversion than doing a mashout.

No, the enzymatic process does not stop. It is still continuing in the grains and in the wort. But it is not a problem since you will raise the temperature soon when you begin the boil. The process stops when the right temperature is reached.

The concern with doing a mashout comes into play when doing afly sparge which can take a hour while the conversion continues.

The concern with doing a mashout comes into play when doing afly sparge which can take a hour while the conversion continues.

jekeane

Well-Known Member

It's purely anecdotal but every time I do a mashout I get better efficiency. I pull the bag heat the wort to 180ish and drop the bag back down to stir and let sit for 5-10 minutes. Then I pull the bag again and squeeze. I average mid 80's but when I mashout I hit 90-92.

It's purely anecdotal but every time I do a mashout I get better efficiency. I pull the bag heat the wort to 180ish and drop the bag back down to stir and let sit for 5-10 minutes. Then I pull the bag again and squeeze. I average mid 80's but when I mashout I hit 90-92.

Thats because the hotter the wort the more soluble the sugars.

pretzelb

Well-Known Member

No, the enzymatic process does not stop. It is still continuing in the grains and in the wort. But it is not a problem since you will raise the temperature soon when you begin the boil. The process stops when the right temperature is reached.

The concern with doing a mashout comes into play when doing afly sparge which can take a hour while the conversion continues.

Right. I was thinking with biab you could hoist the bag, ramp up the heat, pour some sparge if you want, but then just keep going to boil. I couldn't think of a reason to ramp to 170 and pause.

It's purely anecdotal but every time I do a mashout I get better efficiency. I pull the bag heat the wort to 180ish and drop the bag back down to stir and let sit for 5-10 minutes. Then I pull the bag again and squeeze. I average mid 80's but when I mashout I hit 90-92.

If you get an efficiency improvement by doing a mash out, it is because your saccharification (starch to sugar conversion) is incomplete. Alpha amylase will work faster at higher temperatures, until it has time to denature, at which point conversion will cease. Denaturing is not instantaneous at mash out temps.

If you had converted all of the starch during your allotted mash time, there would be no remaining starch to convert during the mash out, and there would be no increase in efficiency.

Brew on

Thats because the hotter the wort the more soluble the sugars.

While it is true that you can dissolve more sugar at higher temps, it does not matter. At 151°F, you can dissolve 66.7 wt% maltose in water. That is: 33.3 gm of water will dissolve 66.7 gm of maltose (1 lb of water [a little more than a pint] will dissolve 2 lb of maltose.) 66.7 wt% sugar is 66.7°Plato, which is equivalent to an SG of greater than 1.330. You can't get anywhere near that kind of sugar concentration in a mash, so you don't need hotter water to get all the sugar to dissolve.

You might counter with: "Well, the hotter water will make the sugar dissolve faster." Again, it doesn't matter. The sugar in a mash is in solution (dissolved) when it is created. There is never any solid sugar present in a mash which needs to be dissolved.

Brew on

Maybe at higher temperature the wort is less viscous also and therefore better to train....

The viscosity of pure sugar solutions does decrease at higher temperatures, however, wort is not a simple sugar solution (it contains proteins, etc.) which can affect the viscosity differently with temperature. There is some literature that suggests that viscosity can actually increase during a mash out:

"Coagulation of mash particles is favoured by an increase in final mash temperature, though this may also increase wort viscosity, which will tend to offset the beneficial effects of coagulation on run off rates." https://bsgcraftbrewing.com/Resourc...es_and_Techniques/WortandBeerFiningManual.pdf

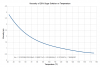

In any case the viscosity drop of a 20 Plato (SG = 1.083) sugar solution going from 150 F to 170 F is not dramatic. Using data from: http://www.engineeringtoolbox.com/sugar-solutions-dynamic-viscosity-d_1895.html the viscosity vs. temp looks like the following:

With BIAB, you normally have a much thinner mash than for other methods, and the viscosity reduction due to that is more important for grain draining than the temperature effect.

Brew on

The viscosity of pure sugar solutions does decrease at higher temperatures, however, wort is not a simple sugar solution (it contains proteins, etc.) which can affect the viscosity differently with temperature. There is some literature that suggests that viscosity can actually increase during a mash out:"Coagulation of mash particles is favoured by an increase in final mash temperature, though this may also increase wort viscosity, which will tend to offset the beneficial effects of coagulation on run off rates." https://bsgcraftbrewing.com/Resourc...es_and_Techniques/WortandBeerFiningManual.pdf

In any case the viscosity drop of a 20 Plato (SG = 1.083) sugar solution going from 150 F to 170 F is not dramatic. Using data from: http://www.engineeringtoolbox.com/sugar-solutions-dynamic-viscosity-d_1895.html the viscosity vs. temp looks like the following:

View attachment 310515

With BIAB, you normally have a much thinner mash than for other methods, and the viscosity reduction due to that is more important for grain draining than the temperature effect.

Brew on

Doug, I've missed you. Welcome back.

Thanks. It's nice when people notice that you are gone.Doug, I've missed you. Welcome back.

Brew on

pricelessbrewing

Brewer's Friend Software Manager

Doug, I've missed you. Welcome back.

Couldn't agree more.

Was going to say all of that, but with much less credibility and lack of sources and nice graphs...

Similar threads

- Replies

- 6

- Views

- 836