SnowRaven

Well-Known Member

- Joined

- Jan 6, 2014

- Messages

- 128

- Reaction score

- 9

(PREFACE : Had Sent this to Spike and was told to look at what BeerSmith software recommenced) SMH

SO here is where I am at, I Upgrading My Current setup / MegaPot 10Gallon Boil, MegaPot 10Gallon Mash, Generic 14.5Gallon HLT

I currently brew for Corney Kegs (5 Gallons finished)

(need to order one of the below SPIKE KETTLE to start)

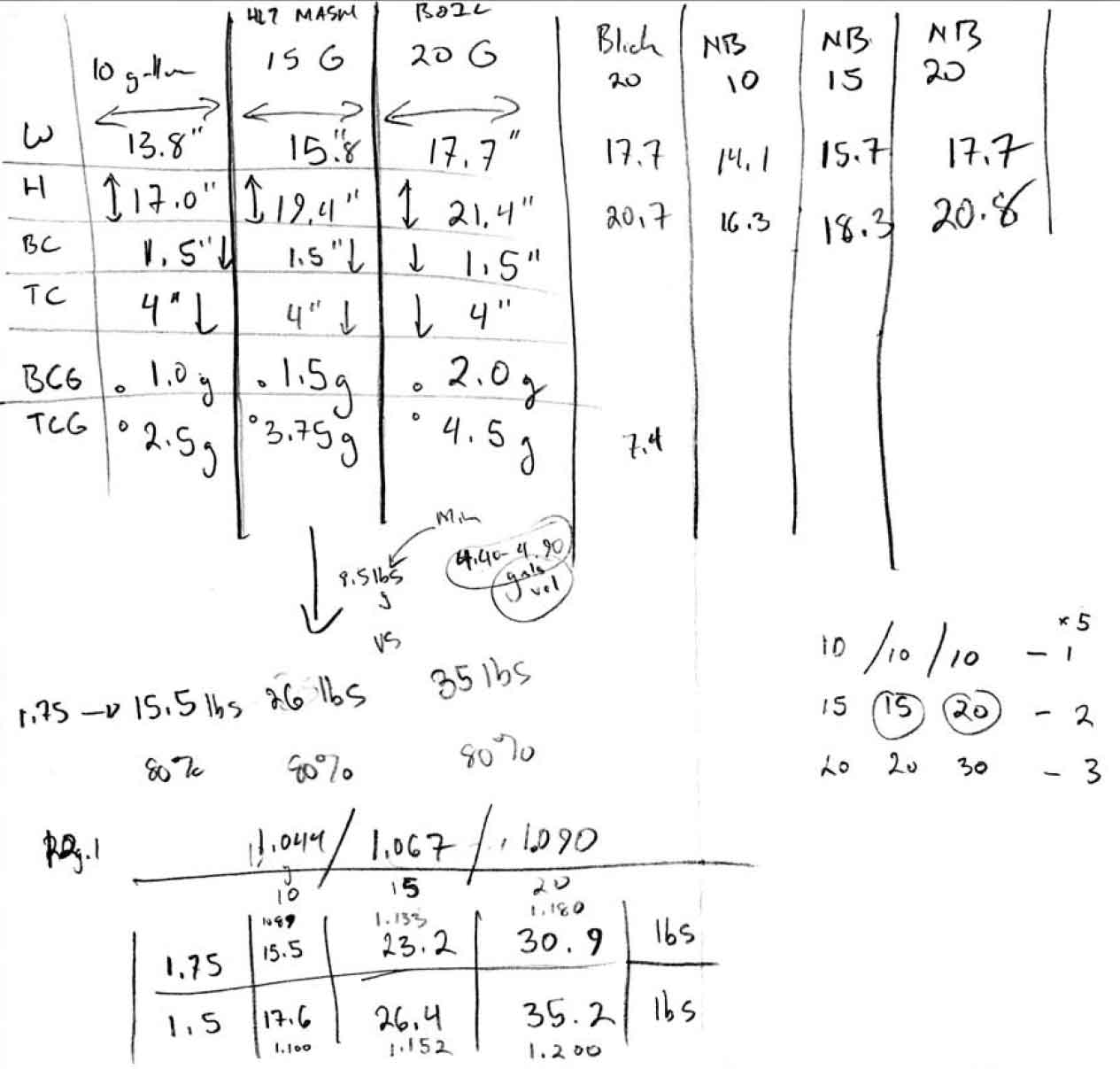

I am debating the SPIKE 15G (site glass) vs the SPIKE 20G (Site Glass) for a Mash Laughter Tun for my RIMMS (using the Blichman Gas Controller / RTD + Recirculation)

with The Ultimate Sparge Arm / USA

Can adjust from the top of your kettle to 12-13 inches down into your kettle

A single, large diameter outlet port trickles onto a stainless disc, which distributes sparge water gently and evenly. This port is also much easier to flush out and keep clean than many other sparge assemblies with multiple small holes that grain gets stuck in during recirculation

Stainless tube measures 18.5" from the top to the bend, and 8.5" from the bottom to the center of the distribution disc.

Can be mounted on a lip that is up to 7/8" wide

this USA is really 9" and in the 20G it would match up much better to the center ( love this device - https://www.morebeer.com/products/ultimate-sparge-arm.html )

and in the end What I am really looking to have, in the last kettles I will need to buy to produce 6 or 12 gallons to fill 1 or 2 corneys (5 gallons)

So my Questions:

Can I still do a (10-12 lbs of Grain with 3.75-4.0 gallons of water) 6 Gallon 1.040 batch in either of these,

SPIKE 15G or 20G -in the site glass model. (60% of my brewing)

I do do batches with 22 lbs of grain at 6 gallons (1.099 range)

Key Question

(**** or do I need to order Special order Horizontal versions with site glasses? if I want to have this capability? Will a 15G or 20G Horizontal even work)

So

I am looking for the capability to do either/both 6 & 12 gallon

all grain batches

(mostly 1.040 to 1.060 / (6 or 12 gallons)

but will sometimes do a double - triple 1.100 (at 6 gallons)

So in the end I will I have a setup / Spike 20Gallon Boil, Spike 15Gallon Mash, Spike 15 Gallon HLT

Numbers I have been basing things off provided by Blichman Eng data

HLT / Mash / Boil

10 gal batch: 15 / 15 / 20

15-20 gal batch: 20 / 20 / 30

or

10 / 20: Setup

10 gal -> 30 / 15 / 20 20 gal -> 15 / 20 / 30

I really appreciate any advice you can provide

aka do I eventually order a 15G and 20G (both with SiteGlass) with TriClamp so I can do the Boil in either?

or do I really need a 15 15 setup?

SO here is where I am at, I Upgrading My Current setup / MegaPot 10Gallon Boil, MegaPot 10Gallon Mash, Generic 14.5Gallon HLT

I currently brew for Corney Kegs (5 Gallons finished)

(need to order one of the below SPIKE KETTLE to start)

I am debating the SPIKE 15G (site glass) vs the SPIKE 20G (Site Glass) for a Mash Laughter Tun for my RIMMS (using the Blichman Gas Controller / RTD + Recirculation)

with The Ultimate Sparge Arm / USA

Can adjust from the top of your kettle to 12-13 inches down into your kettle

A single, large diameter outlet port trickles onto a stainless disc, which distributes sparge water gently and evenly. This port is also much easier to flush out and keep clean than many other sparge assemblies with multiple small holes that grain gets stuck in during recirculation

Stainless tube measures 18.5" from the top to the bend, and 8.5" from the bottom to the center of the distribution disc.

Can be mounted on a lip that is up to 7/8" wide

this USA is really 9" and in the 20G it would match up much better to the center ( love this device - https://www.morebeer.com/products/ultimate-sparge-arm.html )

and in the end What I am really looking to have, in the last kettles I will need to buy to produce 6 or 12 gallons to fill 1 or 2 corneys (5 gallons)

So my Questions:

Can I still do a (10-12 lbs of Grain with 3.75-4.0 gallons of water) 6 Gallon 1.040 batch in either of these,

SPIKE 15G or 20G -in the site glass model. (60% of my brewing)

I do do batches with 22 lbs of grain at 6 gallons (1.099 range)

Key Question

(**** or do I need to order Special order Horizontal versions with site glasses? if I want to have this capability? Will a 15G or 20G Horizontal even work)

So

I am looking for the capability to do either/both 6 & 12 gallon

all grain batches

(mostly 1.040 to 1.060 / (6 or 12 gallons)

but will sometimes do a double - triple 1.100 (at 6 gallons)

So in the end I will I have a setup / Spike 20Gallon Boil, Spike 15Gallon Mash, Spike 15 Gallon HLT

Numbers I have been basing things off provided by Blichman Eng data

HLT / Mash / Boil

10 gal batch: 15 / 15 / 20

15-20 gal batch: 20 / 20 / 30

or

10 / 20: Setup

10 gal -> 30 / 15 / 20 20 gal -> 15 / 20 / 30

I really appreciate any advice you can provide

aka do I eventually order a 15G and 20G (both with SiteGlass) with TriClamp so I can do the Boil in either?

or do I really need a 15 15 setup?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)